Fordson Major Pump install issues

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Fordson Major Pump install issues

I have a 1958 Fordson Major Backhoe loader engine # 1415161 I had a mechanic shop remove and replace the head, check the fuel lines, re-do the diesel pump. They almost got it working but said my injector pump was bad so it sat for a few months. I recently bought a rebuilt SIMMS injector from ebay and I am having problems installing it. I was able to install it and prime the injectors, and get the tractor to run. The mechanics told me to run some ether into it, and eventually it did idle and rev up and I was able to drive around (no power steering) But ever since then, I have been unable to get it to start again abesent of an entire can of starter fluid. My current theory is that the Injector Pump Coupling was bad or that one of the Injector Pump Coupling adjustment bolts were loose.

I looked at the Injector Pump Coupling, and it did appear to be heavily warn. I bought a new coupler (from amazon of all places). The new coupler is one piece. The coupler on the tractor is two separate & thinner pieces. I have not yet installed the new one piece it. Why is the old one two pieces and the replacement one (old style, yellow) one piece? Also, it is not immediately obvious how the adjustment is done. Is the pump armature adjusted while the coupler pushes against the new adjustment using the two bolts? Isn't that a pretty bad design, or am I missing something?

Second issue, I am unable to find the flywheel timing mark opening. The mechanic said it is near the starter. I can't for the life of me find it. From the Fordson Fuel manual, my engine (Mark III #1415161 ) should be 23 degrees. My question is, where exactly is the Flywheel Timing Mark opening? Remember, this is a backhoe, and there is a large loader installed on it -- so the loader part might be obscuring where it might be. I'm just not finding it and its frustrating.

Third question, when/if I do find the timing mark, how do I rotate the engine? Do I use the starter until it lines up? Or do I put a breaker bar on the front of the engine and turn it?

The mechanic, when it was at their shop, before I had the new injector on, cranked it relentlessly to get it to run. There are two 6v heavy duty commercial tractor batteries installed. They cost a fortune. The mechanic was cranking it, and I remember him cranking it for several half minutes. But now, when I run it -- I can barely get it to crank for perhaps more then once or twice perhaps 5 or 6 seconds before the batteries are dead and I have to charge them. However, the batteries test good under a load charger. Combined the should provide 1600 amps. With the smoke from the cable, I'm pretty sure it probably is actually pushing that much. I also get a lot of smoke from the cables. So I replaced all of the connectors, put on electric gel, and replaced the relay. I am still getting smoke and dead batteries after a few cranks. The problem is, it takes almost two days for me to charge the batteries to try any adjustment. I brought in my start to the mechanic shop and they check it out. It tested good. The starter appears to crank the engire backhoe hydrolic pumps when it starts. There are three pumps on it (yeah its a old backhoe), front, one on the side (?), and I think one behind the backhoe as the PTO. I do not know how to disengage the PTO -- would this help with my starter? Right now, if I make any changes, I get one or two cranks, and I have to recharge both batteries. Is there a better setup?

Fourth question, the generator and voltage regulator: I do not think my battery is getting a charge. I looked, and I can get a new generator for $120 and a new relay for $50. Before I do this, what should I do to check my setup before I shell out money?

Hopefully I got the right forum -- is the Major the same as the New Major? Thanks

Edit: Typos

I looked at the Injector Pump Coupling, and it did appear to be heavily warn. I bought a new coupler (from amazon of all places). The new coupler is one piece. The coupler on the tractor is two separate & thinner pieces. I have not yet installed the new one piece it. Why is the old one two pieces and the replacement one (old style, yellow) one piece? Also, it is not immediately obvious how the adjustment is done. Is the pump armature adjusted while the coupler pushes against the new adjustment using the two bolts? Isn't that a pretty bad design, or am I missing something?

Second issue, I am unable to find the flywheel timing mark opening. The mechanic said it is near the starter. I can't for the life of me find it. From the Fordson Fuel manual, my engine (Mark III #1415161 ) should be 23 degrees. My question is, where exactly is the Flywheel Timing Mark opening? Remember, this is a backhoe, and there is a large loader installed on it -- so the loader part might be obscuring where it might be. I'm just not finding it and its frustrating.

Third question, when/if I do find the timing mark, how do I rotate the engine? Do I use the starter until it lines up? Or do I put a breaker bar on the front of the engine and turn it?

The mechanic, when it was at their shop, before I had the new injector on, cranked it relentlessly to get it to run. There are two 6v heavy duty commercial tractor batteries installed. They cost a fortune. The mechanic was cranking it, and I remember him cranking it for several half minutes. But now, when I run it -- I can barely get it to crank for perhaps more then once or twice perhaps 5 or 6 seconds before the batteries are dead and I have to charge them. However, the batteries test good under a load charger. Combined the should provide 1600 amps. With the smoke from the cable, I'm pretty sure it probably is actually pushing that much. I also get a lot of smoke from the cables. So I replaced all of the connectors, put on electric gel, and replaced the relay. I am still getting smoke and dead batteries after a few cranks. The problem is, it takes almost two days for me to charge the batteries to try any adjustment. I brought in my start to the mechanic shop and they check it out. It tested good. The starter appears to crank the engire backhoe hydrolic pumps when it starts. There are three pumps on it (yeah its a old backhoe), front, one on the side (?), and I think one behind the backhoe as the PTO. I do not know how to disengage the PTO -- would this help with my starter? Right now, if I make any changes, I get one or two cranks, and I have to recharge both batteries. Is there a better setup?

Fourth question, the generator and voltage regulator: I do not think my battery is getting a charge. I looked, and I can get a new generator for $120 and a new relay for $50. Before I do this, what should I do to check my setup before I shell out money?

Hopefully I got the right forum -- is the Major the same as the New Major? Thanks

Edit: Typos

Re: Fordson Major Pump install issues

Hi welcome to the board.

Does not sound as if your mechanic has any experience with these tractors at all. Using ether to start her is the sure way of ruining the engine if it has not already happened. From your description the engine sounds like it is out of time and if the pump has been off and not replaced correctly this could be your problem.

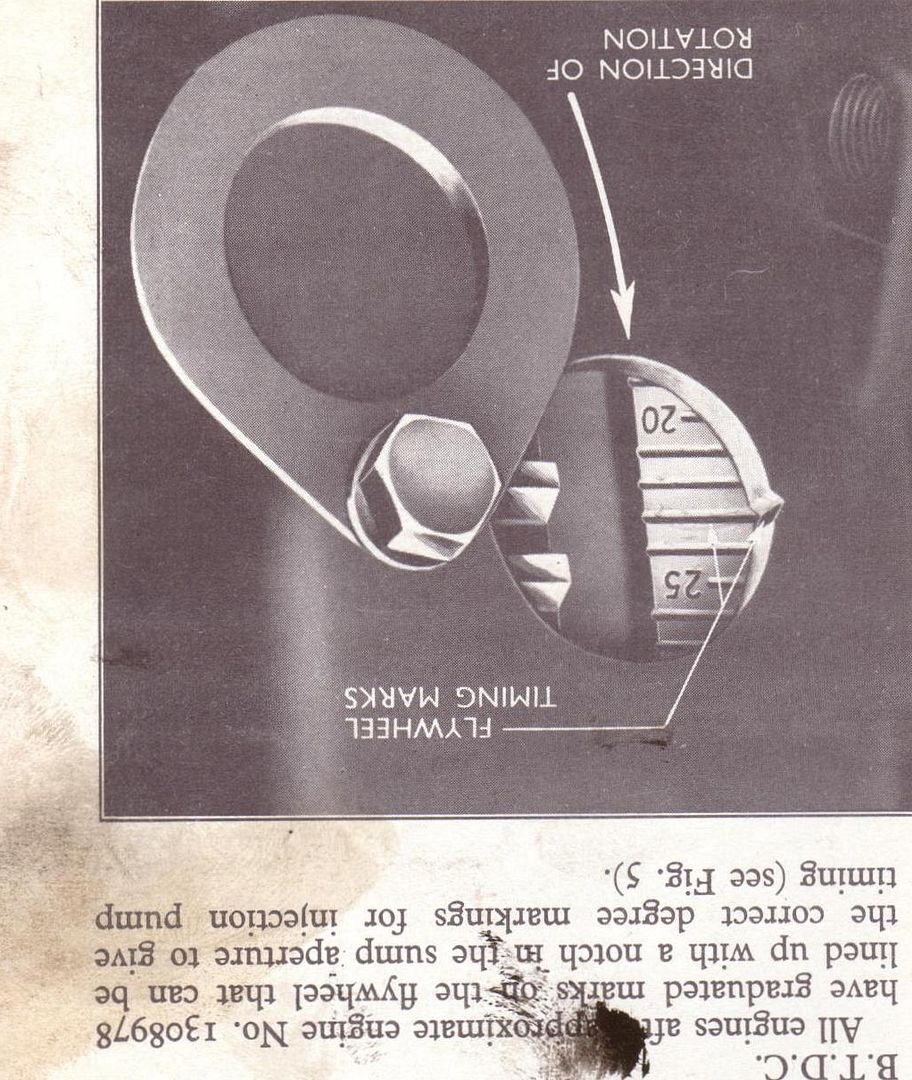

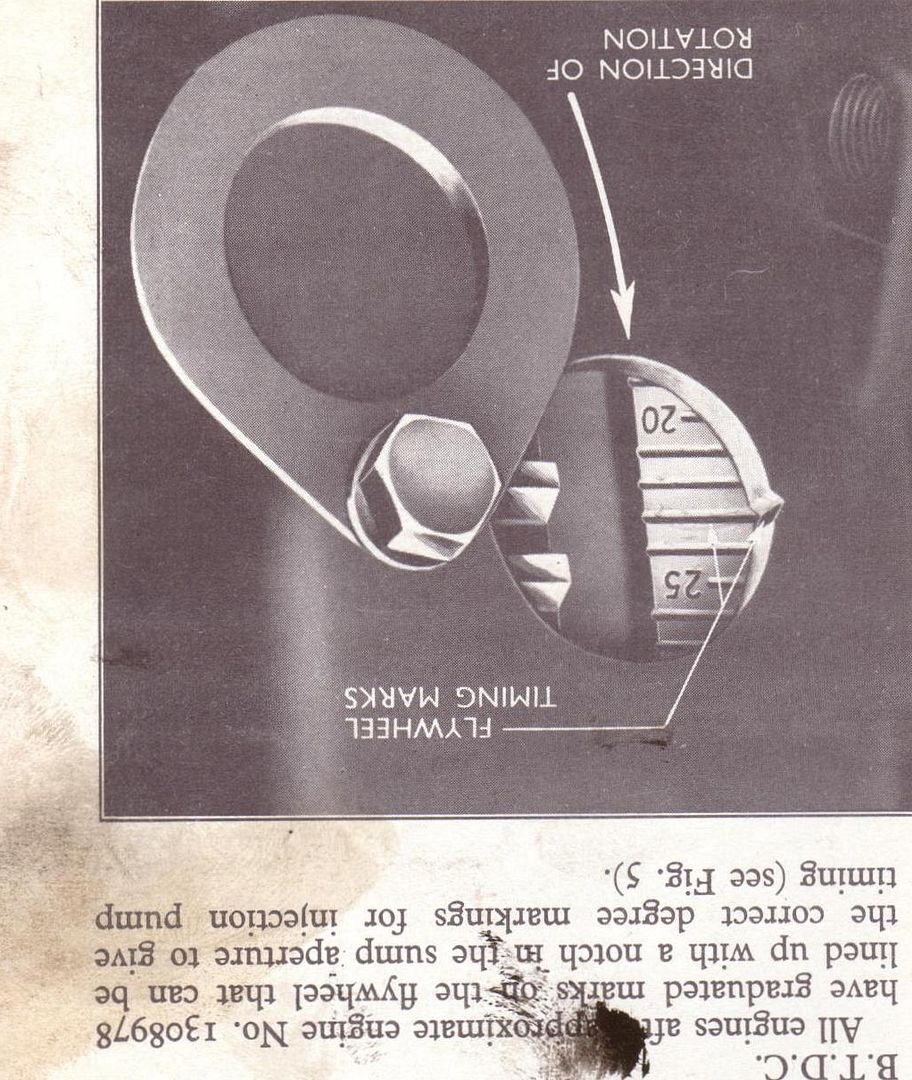

Your engine number is from February 1957 not 1958 and this could be the reason you cannot find a timing cover hole in your sump. It is possible that you have a pointer and a notch on the front crankshaft pulley to line up. Your engine number is close to the change and they could have been using up stock parts.

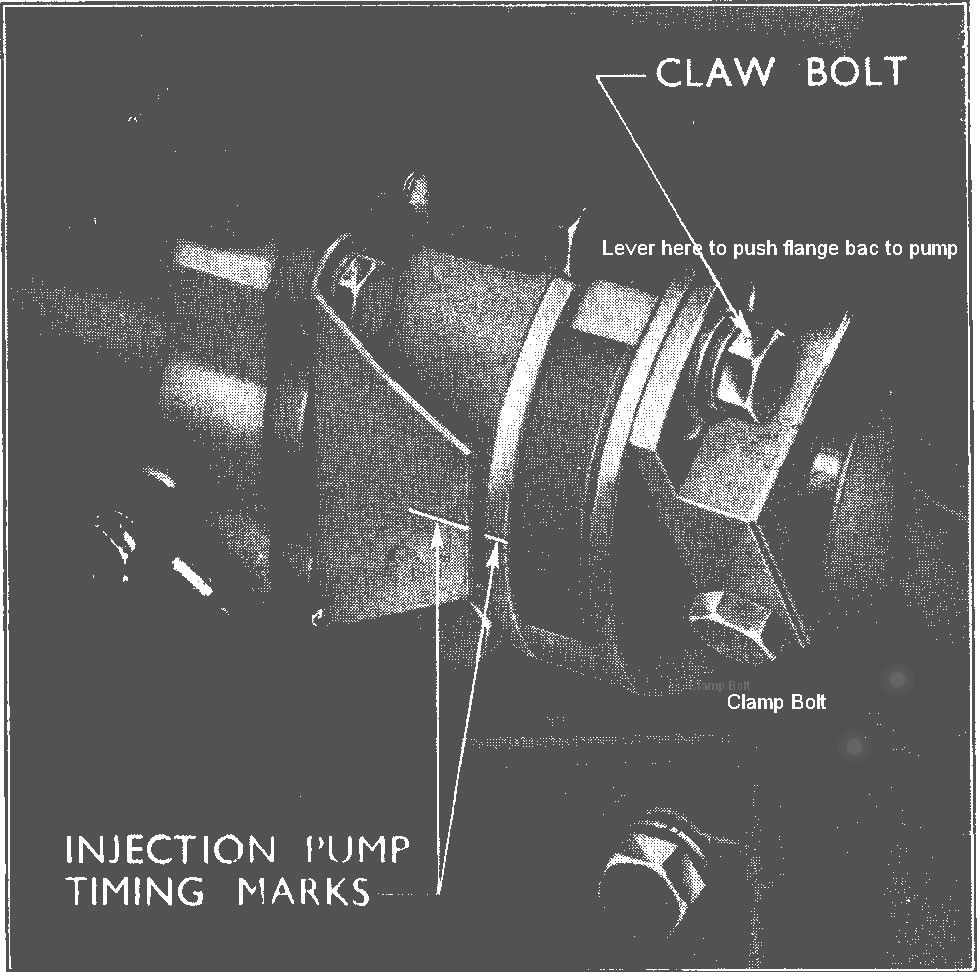

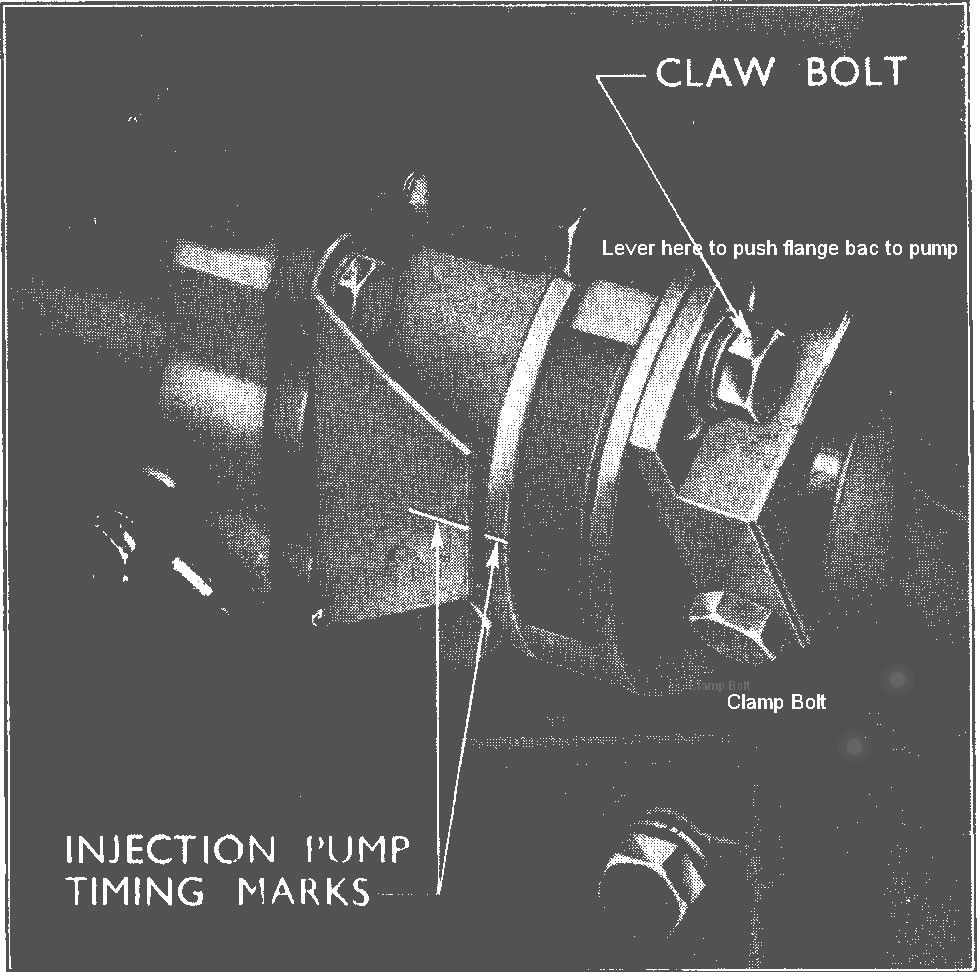

The marks on your drive coupling should look like this and the drive should be a single fibre pad. Some tractors have been fitted with a "Quiet" coupling from a truck, over the years. It is normal for Majors to clatter a bit in this area.

The timing window will be in the sump on the pump side, if you have one.

The timing marks line up in two positions in the engines cycle. BTDC No. 1 and BTDC No. 4. It is important that you fit the pump and line up the marks on BTDC No.1. Note the position of the clamp bolt in the first picture, slightly below the drive shaft is No.1, above the drive shaft is No.4.

I turn the engine on either the fan or bump the starter until it is nearly in position then turn it with a screw driver in the starter ring gear teeth to get the marks to line up.

To disconnect the PTO there is a flat lever near the clutch pedal that puts the PTO in and out of gear. You have to use the clutch like the main gear shift to get it into gear.

When you get her running, at about 1200 rpm but a volt meter across the battery terminals + to -, you should have around 13.6 to 14.5 volts. If it remains around 12 volts or less you should replace dynamo and regulator. The regulator is behind the lower dash panel, you will need to dismantle the instrument panel to get to it. You could replace just the dynamo but, if the regulator is the cause of the original dynamo failure, it will happen again.

Does not sound as if your mechanic has any experience with these tractors at all. Using ether to start her is the sure way of ruining the engine if it has not already happened. From your description the engine sounds like it is out of time and if the pump has been off and not replaced correctly this could be your problem.

Your engine number is from February 1957 not 1958 and this could be the reason you cannot find a timing cover hole in your sump. It is possible that you have a pointer and a notch on the front crankshaft pulley to line up. Your engine number is close to the change and they could have been using up stock parts.

The marks on your drive coupling should look like this and the drive should be a single fibre pad. Some tractors have been fitted with a "Quiet" coupling from a truck, over the years. It is normal for Majors to clatter a bit in this area.

The timing window will be in the sump on the pump side, if you have one.

The timing marks line up in two positions in the engines cycle. BTDC No. 1 and BTDC No. 4. It is important that you fit the pump and line up the marks on BTDC No.1. Note the position of the clamp bolt in the first picture, slightly below the drive shaft is No.1, above the drive shaft is No.4.

I turn the engine on either the fan or bump the starter until it is nearly in position then turn it with a screw driver in the starter ring gear teeth to get the marks to line up.

To disconnect the PTO there is a flat lever near the clutch pedal that puts the PTO in and out of gear. You have to use the clutch like the main gear shift to get it into gear.

When you get her running, at about 1200 rpm but a volt meter across the battery terminals + to -, you should have around 13.6 to 14.5 volts. If it remains around 12 volts or less you should replace dynamo and regulator. The regulator is behind the lower dash panel, you will need to dismantle the instrument panel to get to it. You could replace just the dynamo but, if the regulator is the cause of the original dynamo failure, it will happen again.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

I guess the pto hydraulic pump powers your backhoe and the crankshaft pump drives the front loader, or vice versa? The pump (belt-driven) on the side of the engine will be the power-steering pump. Some photos would be interesting!

If the starter cables are smoking then they are not big enough: however I guess you mean the crimp-on terminals on the ends are smoking, so you're as well to get all-new cables made up, of a suitable size; something like this: http://www.ebay.co.uk/itm/POSITIVE-EART ... qGC9Qc8s_w . Cranking for long periods won't do the starter any good, although I wouldn't expect it to harm the batteries. It shouldn't take long to recharge them, even with a small 4-amp 'car' charger; maybe the battery terminals aren't connecting properly?

If the starter cables are smoking then they are not big enough: however I guess you mean the crimp-on terminals on the ends are smoking, so you're as well to get all-new cables made up, of a suitable size; something like this: http://www.ebay.co.uk/itm/POSITIVE-EART ... qGC9Qc8s_w . Cranking for long periods won't do the starter any good, although I wouldn't expect it to harm the batteries. It shouldn't take long to recharge them, even with a small 4-amp 'car' charger; maybe the battery terminals aren't connecting properly?

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Can you tell me what the Sump Aperture looks like and how to identify it? What does it do? If I find it, the timing window should be there if I have one, correct? Is there a picture showing where this part is?

Thanks

Thanks

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

I think I found it. There are two bolts covering a cover near the injector pump. I can not get to the second bolt without removing the pump. I need to replace the coupler anyway, so I'll see if that is it. But since I have no covered area to work in, I have to wait for a break in the rain (it rains here everyday for 5 months). I might get lucky next week. If you have any additional information (like a picture of the Sump to make sure its the right part), that would be awesome. This forum is great i'm glad it exists and thanks in advance for help. I almost have this thing going, I think if I can ask a few more questions and get a little more lucky, I can get this thing working. I will take pictures next time as well.

Re: Fordson Major Pump install issues

The timing window is nowhere near the injection pump, it is on the side of the sump back near the clutch housing flange on the pump side. Look under the side frame, on the sump, under the four bolts that hold the side frame on. It is just like the picture.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

I took this photo by lying on the floor - the timing window is right in the centre of the pic, a round cover plate held on by one 1/2" AF bolt. As yours is a backhoe/loader, it's possible you may not have the tractor chassis rail like here, and instead some other chassis or frame (as our JCB has). The marks you are looking for are actually stamped into the flywheel

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

BlackBob I was able to find it thanks to your picture.

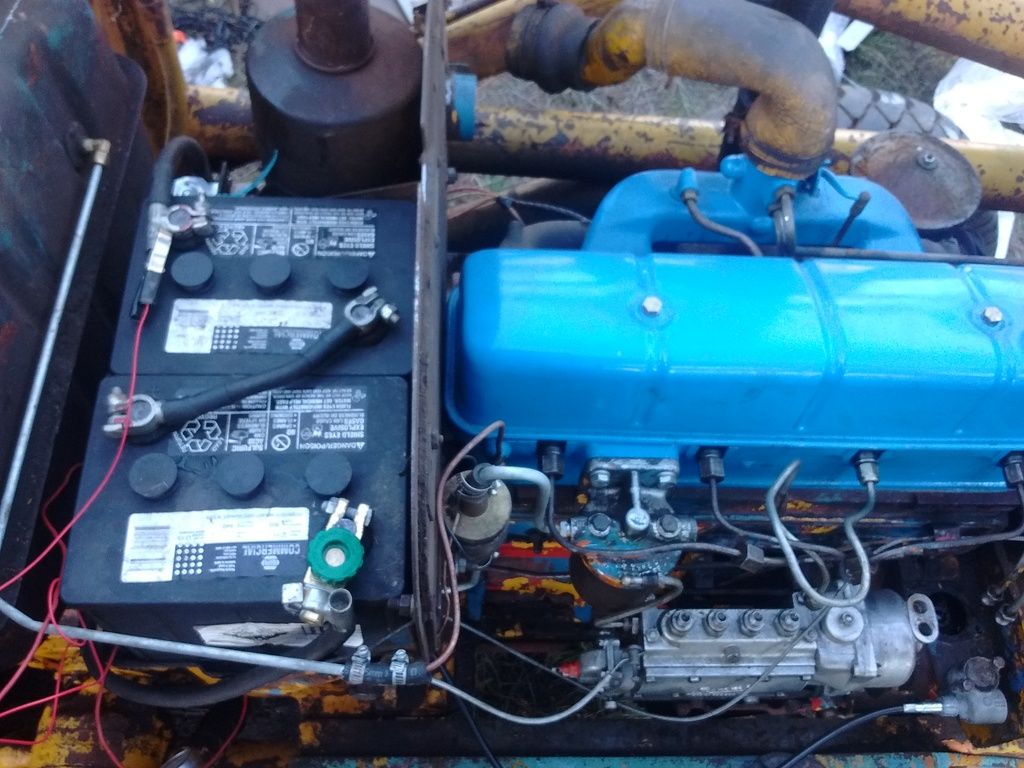

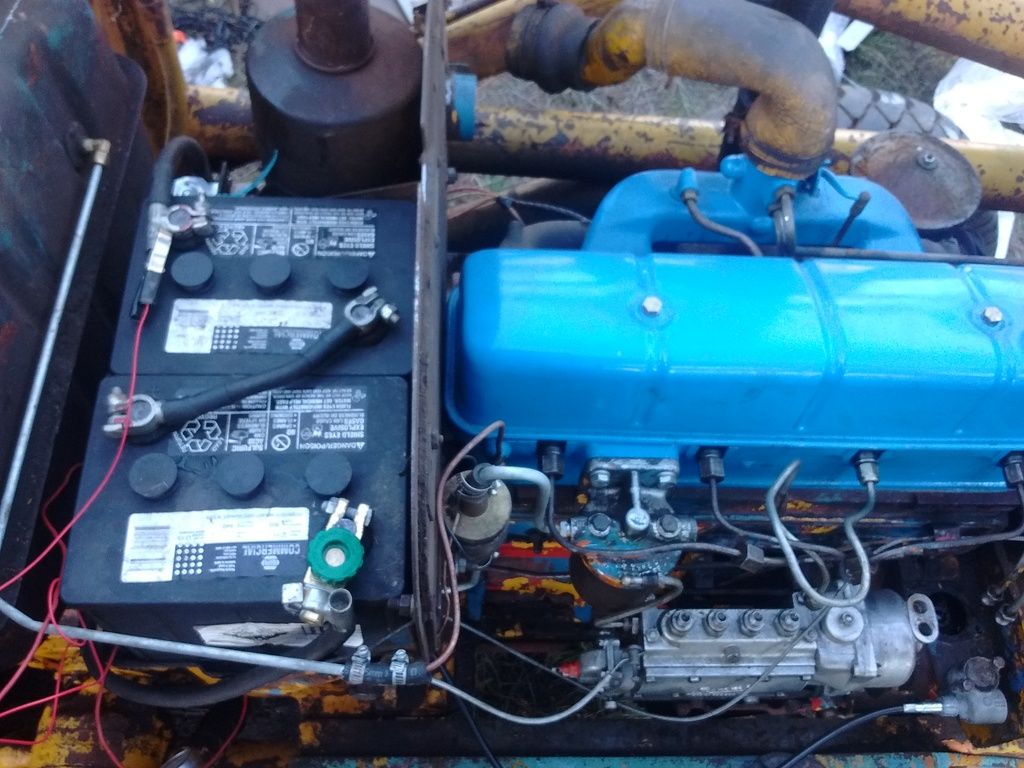

Before I saw you and Brian's post, I went to replace the pump connector and look for the window. I took some pictures for you.

As you requested, here are pictures of the Fordson Backhoe. I do not know much about it. The mechanic guys put on the new parts you see in the pictures. Notice the old paint red, blue, yellow. There are several company logos washed away, painted on top of each other. I am unable to make out any of them.

Before I saw you and Brian's post, I went to replace the pump connector and look for the window. I took some pictures for you.

As you requested, here are pictures of the Fordson Backhoe. I do not know much about it. The mechanic guys put on the new parts you see in the pictures. Notice the old paint red, blue, yellow. There are several company logos washed away, painted on top of each other. I am unable to make out any of them.

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

Wow thanks for the photos, that looks a strong loader and in good condition, I don't pretend to know what make it is but I hope you (we?  ) can get it running properly.

) can get it running properly.

From here I would say your battery cables look fine, we can't see them all but I'd be surprised if any of these ones are smoking? Unless there are some terminals not tight?

You were asking about the pto, if you haven't already found it, it's the vertical lever with the piece of grey pipe on it, pull it back to engage. Yes the front pump will be running continuously even while starting and can't be disengaged, but that shouldn't be a problem if the fuel and electrical systems are in good order.

I don't know if you put on that new-looking piece of chain on the backhoe, but there's no way that would be strong enough to support it if a pipe burst! You wouldn't normally need it unless you are going on the road.. and maybe there is somewhere to put in a locking pin? (can't see one from here)

You wouldn't normally need it unless you are going on the road.. and maybe there is somewhere to put in a locking pin? (can't see one from here)

I don't know anything about the injection pump drive coupling so I'll leave it to others to comment.

Edit: Ahh on looking again I see that you have a hydraulic pump fitted in front of the brake pedals, where a standard tractor has a flat belt pulley to drive sawbenches etc, is this what you mean by pto, I thought you meant at the back of the tractor? Yours doesn't look to have the belt-pulley disengagement lever so that pump will also be running constantly, probably provided the clutch is engaged - and the belt pulley is driven in such a way that it has 2 'speeds' selected by changing the high-low transmission lever - perhaps your pump has too??

From here I would say your battery cables look fine, we can't see them all but I'd be surprised if any of these ones are smoking? Unless there are some terminals not tight?

You were asking about the pto, if you haven't already found it, it's the vertical lever with the piece of grey pipe on it, pull it back to engage. Yes the front pump will be running continuously even while starting and can't be disengaged, but that shouldn't be a problem if the fuel and electrical systems are in good order.

I don't know if you put on that new-looking piece of chain on the backhoe, but there's no way that would be strong enough to support it if a pipe burst!

I don't know anything about the injection pump drive coupling so I'll leave it to others to comment.

Edit: Ahh on looking again I see that you have a hydraulic pump fitted in front of the brake pedals, where a standard tractor has a flat belt pulley to drive sawbenches etc, is this what you mean by pto, I thought you meant at the back of the tractor? Yours doesn't look to have the belt-pulley disengagement lever so that pump will also be running constantly, probably provided the clutch is engaged - and the belt pulley is driven in such a way that it has 2 'speeds' selected by changing the high-low transmission lever - perhaps your pump has too??

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

Re: Fordson Major Pump install issues

If you put the High/Low lever into neutral (between the upper and lower positions), the pump driven off the pulley drive (by your right foot) will be disengaged.

Tim E

Tim E

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Thanks Tim, Bob, and Brian.

Today I went to move the flywheel to the timing mark first with the starter. short story: The starter does not work and is broken. long story: I installed the batteries. I hit the start, and the starter did not turn. I removed the starter, and tested the switch: the starter turned. Then I moved the start gear with a screw driver, the engine turned easily. So then I by passed the starter's power with jumper cables, and manually engaged the starter -- thinking there wasn't enough juice somewhere in the relay/starter wiring. The starter (not installed) moved freely. Then I re-installed the starter, and manually engaged the starter gear, and turned it. It would NOT turn. The starter does not have enough torque to turn the motor (although a screwdriver can) but turns uninstalled fine.

So I took the starter to the mechanics who worked on it. Previously, the backhoe was at their shop. When it was there, they did a re-wire. At one point, they had the batteries in PARALLEL (not SERIES), and I told them that was wrong. They told me I was wrong. They seemed pretty sure about it, but I insisted they test it. They refused. Eventually, they said I had problems with my starter and removed and cleaned it. They got it working (at 6v!) I told them again, NO it is wired wrong, and forced them to test it. They saw that it was 6v and immediately fixed it. I told them they could have wrecked something by undervolting things.

I think they did wreck the starter, by undervolting it, when the had the battery hooked up wrong, and it just took until now for me to realize it.I told them my theory, of course they denied it. They said it wasn't possible to undervolt electric motors, I tried to explain to them they did not care. I didn't tell them, but I know they are to proud of being stupid to admit they screwed it up. Anyway, they are not helping (after charging me hundreds of dollars on working on the starter). I have a blown starter now. I ask them if they would make it right, they said yes, and left it over there. But now I am thinking I am going to go back and pick it up.

So I am unable to start the backhoe without a working starter. I looked at I can get a new one for $300. Unfortunately, I am in dire financial situation and cannot afford it now. If I had $300, I would need to rent a backhoe anyway because there are some emergencies on the farm I need to move some heavy things anyway. So I'm damned if I do and damned if I don't.

So my question is, with a small budget, is it possible to fix my starter to get enough torque to get it to start the backhoe? Or is it possible there is a bolt-on motor/spindle, that I can easily modify (even with a welder) just to get by? I have a starter from a Ford 300 inline 6 motor I wanted to see if I could weld the spindle directly to the old stelnoid mechanism? is this crazy?

What about getting the starter re-built at a local re-build shop? Is that an option?

Also I noticed there is a starter that will apparently retrofit onto my Fordson. The model number is S65575, is sold as a replacement fit for Fordson. It seems like the starter is for various other brands of tractors. Here is one: http://www.ebay.com/itm/New-Sparex-STAR ... Swu-BWPp-2

Its cheaper then the "Original" $300 Fordson starter I found on amazon: https://www.amazon.com/FORDSON-DDN11000 ... B00KLGY6ZS

$300 isn't bad, but $180 is better. But if there is something I can do even cheaper or free, or to fix it, that would be best. Or a rebuild? I've already spent $200+ to this mechanic shop for them to fix it, they basically broke it in the first place.

Any suggestions?

The good news is, I manually turned the starter gear with a screw driver. And after 45 minutes and almost giving up, I did find the timing mark. Tomorrow I will install the coupling and bolt the pump back on at the correct timing mark. But I will not be able to prime the pump, or start it now.

Today I went to move the flywheel to the timing mark first with the starter. short story: The starter does not work and is broken. long story: I installed the batteries. I hit the start, and the starter did not turn. I removed the starter, and tested the switch: the starter turned. Then I moved the start gear with a screw driver, the engine turned easily. So then I by passed the starter's power with jumper cables, and manually engaged the starter -- thinking there wasn't enough juice somewhere in the relay/starter wiring. The starter (not installed) moved freely. Then I re-installed the starter, and manually engaged the starter gear, and turned it. It would NOT turn. The starter does not have enough torque to turn the motor (although a screwdriver can) but turns uninstalled fine.

So I took the starter to the mechanics who worked on it. Previously, the backhoe was at their shop. When it was there, they did a re-wire. At one point, they had the batteries in PARALLEL (not SERIES), and I told them that was wrong. They told me I was wrong. They seemed pretty sure about it, but I insisted they test it. They refused. Eventually, they said I had problems with my starter and removed and cleaned it. They got it working (at 6v!) I told them again, NO it is wired wrong, and forced them to test it. They saw that it was 6v and immediately fixed it. I told them they could have wrecked something by undervolting things.

I think they did wreck the starter, by undervolting it, when the had the battery hooked up wrong, and it just took until now for me to realize it.I told them my theory, of course they denied it. They said it wasn't possible to undervolt electric motors, I tried to explain to them they did not care. I didn't tell them, but I know they are to proud of being stupid to admit they screwed it up. Anyway, they are not helping (after charging me hundreds of dollars on working on the starter). I have a blown starter now. I ask them if they would make it right, they said yes, and left it over there. But now I am thinking I am going to go back and pick it up.

So I am unable to start the backhoe without a working starter. I looked at I can get a new one for $300. Unfortunately, I am in dire financial situation and cannot afford it now. If I had $300, I would need to rent a backhoe anyway because there are some emergencies on the farm I need to move some heavy things anyway. So I'm damned if I do and damned if I don't.

So my question is, with a small budget, is it possible to fix my starter to get enough torque to get it to start the backhoe? Or is it possible there is a bolt-on motor/spindle, that I can easily modify (even with a welder) just to get by? I have a starter from a Ford 300 inline 6 motor I wanted to see if I could weld the spindle directly to the old stelnoid mechanism? is this crazy?

What about getting the starter re-built at a local re-build shop? Is that an option?

Also I noticed there is a starter that will apparently retrofit onto my Fordson. The model number is S65575, is sold as a replacement fit for Fordson. It seems like the starter is for various other brands of tractors. Here is one: http://www.ebay.com/itm/New-Sparex-STAR ... Swu-BWPp-2

Its cheaper then the "Original" $300 Fordson starter I found on amazon: https://www.amazon.com/FORDSON-DDN11000 ... B00KLGY6ZS

$300 isn't bad, but $180 is better. But if there is something I can do even cheaper or free, or to fix it, that would be best. Or a rebuild? I've already spent $200+ to this mechanic shop for them to fix it, they basically broke it in the first place.

Any suggestions?

The good news is, I manually turned the starter gear with a screw driver. And after 45 minutes and almost giving up, I did find the timing mark. Tomorrow I will install the coupling and bolt the pump back on at the correct timing mark. But I will not be able to prime the pump, or start it now.

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Hi. I am doing more research. It looks like I can buy a rebuild kit and maybe with everyone help, do it myself. I think it is a Lucas starter and I am looking for a a starter rebuild kit much like this one:

http://www.jcrsupplies.co.uk/products/S ... _KIT_.html

or

http://www.aspwholesale.com/starter-reb ... lucas.html

Am I on the right track? How do I narrow down which exact part kit I need? Is this the correct path to repair my starter?

http://www.jcrsupplies.co.uk/products/S ... _KIT_.html

or

http://www.aspwholesale.com/starter-reb ... lucas.html

Am I on the right track? How do I narrow down which exact part kit I need? Is this the correct path to repair my starter?

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

It depends what's wrong with your starter..

The loader is sitting with the bucket on the ground so you can't use another tractor, truck, whatever, to tow-start it..

I've seen people fit modern starters with the solenoid on top, like the one in your first link, so it must be possible. For example, this: http://www.ebay.co.uk/itm/Fordson-Major ... SwQiRUmCXL Ideally you would take the time to wire it to the ignition switch, but if you're in a hurry, hot-wiring by touching the terminals with a spanner would be ok for now?

I would go bring your own starter home, and try to establish what has gone wrong with it. Other people will know a lot more about starters than me, but, if it spins over on the bench but hasn't enough oomph to turn the engine, I think it might be worth gambling a few more dollars on one of those overhaul kits, including brushes etc My worry would be that some of the coils in the starter are damaged/melted, which would be a more specialist repair.

Photobucket is 'closed for maintenance' just now so I can't send any photos meantime.. might be worth having a search for starter repair info on here though?

The loader is sitting with the bucket on the ground so you can't use another tractor, truck, whatever, to tow-start it..

I've seen people fit modern starters with the solenoid on top, like the one in your first link, so it must be possible. For example, this: http://www.ebay.co.uk/itm/Fordson-Major ... SwQiRUmCXL Ideally you would take the time to wire it to the ignition switch, but if you're in a hurry, hot-wiring by touching the terminals with a spanner would be ok for now?

I would go bring your own starter home, and try to establish what has gone wrong with it. Other people will know a lot more about starters than me, but, if it spins over on the bench but hasn't enough oomph to turn the engine, I think it might be worth gambling a few more dollars on one of those overhaul kits, including brushes etc My worry would be that some of the coils in the starter are damaged/melted, which would be a more specialist repair.

Photobucket is 'closed for maintenance' just now so I can't send any photos meantime.. might be worth having a search for starter repair info on here though?

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

Re: Fordson Major Pump install issues

IMHO I would not even consider attempting to repair a starter when a new one is available, I did spend time in the electrical shop servicing these starters back in the day. Back then it was the normal thing to replace the field coils as these did tend to break down due to heating over time. The coils themselves do not fail but the shellac insulation breaks down and the coils short out. Even if the brushes are replaced you will most likely need to skim the commutator, this can be done with emery paper but is far better done on a lathe. You may even find that soldering the new brushes in place is not as simple as it looks.

OK, with time and a little luck you can get it to work but I have tried it a few times over the past few years on Nuffy, Harriet and Super Sue and had to put replacement units on anyway.

The later type Ford starter will fit with a modification to a push button or key type starter switch. All that is required is a switch, wire to switch from the live feed of the battery then a wire from the other switch terminal to the small tag on the solenoid. The only other issue that could cause you a problem is, when the starter is mounted, the solenoid protrudes over the side channel so check it would not foul on your loader.

This later starter could be cheaper than an original type and more easily found.

Check that your clamp bolt on the coupling is to the underside of the shaft when you have your timing marks lined up otherwise you will never get her to start.

OK, with time and a little luck you can get it to work but I have tried it a few times over the past few years on Nuffy, Harriet and Super Sue and had to put replacement units on anyway.

The later type Ford starter will fit with a modification to a push button or key type starter switch. All that is required is a switch, wire to switch from the live feed of the battery then a wire from the other switch terminal to the small tag on the solenoid. The only other issue that could cause you a problem is, when the starter is mounted, the solenoid protrudes over the side channel so check it would not foul on your loader.

This later starter could be cheaper than an original type and more easily found.

Check that your clamp bolt on the coupling is to the underside of the shaft when you have your timing marks lined up otherwise you will never get her to start.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

According to this article, when an electric motor is undervolted, the #1 part that breaks is the insulation between the coils.

http://ecmweb.com/content/how-save-your ... g-brownout

(article is not specific to starters but actually three phase motors, but the science is the same)

"Excess heat is a problem for motors because insulation life is halved for every 10°C increase in temperature (Fig. 2). At the same time, the temperature of the winding will rise 10°C to 15°C for each 10% drop in voltage. That means the insulation life of a motor that operates on 10% lower voltage will decrease to only 50% to 75% of its expected life."

The voltage was probably at, the most, the high side of 6v. So it was most definitely 45% or 50% lower. I'm almost certain this is what killed the starter.

This is my concern that the 6v that was ran into the starter caused it to burn out the insulation, exactly what you are telling me Brian.

So we're off to a new starter. By chance, do you know whats the most economic replacement starter for the Fordson Major?

Also thanks guys.

http://ecmweb.com/content/how-save-your ... g-brownout

(article is not specific to starters but actually three phase motors, but the science is the same)

"Excess heat is a problem for motors because insulation life is halved for every 10°C increase in temperature (Fig. 2). At the same time, the temperature of the winding will rise 10°C to 15°C for each 10% drop in voltage. That means the insulation life of a motor that operates on 10% lower voltage will decrease to only 50% to 75% of its expected life."

The voltage was probably at, the most, the high side of 6v. So it was most definitely 45% or 50% lower. I'm almost certain this is what killed the starter.

This is my concern that the 6v that was ran into the starter caused it to burn out the insulation, exactly what you are telling me Brian.

So we're off to a new starter. By chance, do you know whats the most economic replacement starter for the Fordson Major?

Also thanks guys.

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Brian, Bob, and friends,

http://www.fordsontractorpages.nl/phpbb ... 0CE#p42764

I found this conversation on the forum, from 2014, that looks like will help me with the information regarding the most economical way to install the starter. Again, Brian, you are absolute right about the starter's wiring change modification. It seems like something I can do myself. I found a starter for $110, is my best bet to buy one of these starters (D8NN11000CE, D4NN11000BR, or 83981923) and do the wiring modification? I can afford $110. Is there any risk with these parts and not fitting? Like, has anyone ordered them and not had them work? Before I buy, perhaps somebody here might know?

http://www.fordsontractorpages.nl/phpbb ... 0CE#p42764

I found this conversation on the forum, from 2014, that looks like will help me with the information regarding the most economical way to install the starter. Again, Brian, you are absolute right about the starter's wiring change modification. It seems like something I can do myself. I found a starter for $110, is my best bet to buy one of these starters (D8NN11000CE, D4NN11000BR, or 83981923) and do the wiring modification? I can afford $110. Is there any risk with these parts and not fitting? Like, has anyone ordered them and not had them work? Before I buy, perhaps somebody here might know?

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Hi, I took the part numbers from JonNWY 2014 post to the Mechanics. I told them, that the part numbers of these starters are extremely common (Lucas starters are used on Ford/New Holland/ Case/ IH as JonNWY post explins), and that, if the bolt holes match, it should just work. They have about an acre of donor tractors (they specialize in tractor restoration, I'm sure you guys would go nuts around there. They have a couple older fordson restored as well). So we walked out and the first tractor we looked at -- some early 60s something, looked like a match. They said they would take the starter off, clean it up, and test it and get back to me. So it looks like I might have a solution. So hopefully, things will work out. We have rain again for a week so I might not be able to work on it. I did however work on my carport shop today and frame in one wall with a window, so I can work on things when there is rain.

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

I was going to ask if you are in the Rocky Mountains, but having looked at a map I see that they are further inland?

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Hi, I am located in a rural town inland, 30 nautical miles from the pacific coast, near the northern border of the State of California. But in the state of Oregon.

Basically its way out in the middle of nowhere. The mountains in the picture are the Coastal Range. The nearest monument that is the most famous is probably the Red Wood National Forest, which is about 15 miles away from me. But the terrain where I am at is dramatically different then the Red Wood Forest because I am further away from the coast. But you could go there on your lunch break.

https://www.google.com/maps/place/O'Bri ... 8584?hl=en

Basically its way out in the middle of nowhere. The mountains in the picture are the Coastal Range. The nearest monument that is the most famous is probably the Red Wood National Forest, which is about 15 miles away from me. But the terrain where I am at is dramatically different then the Red Wood Forest because I am further away from the coast. But you could go there on your lunch break.

https://www.google.com/maps/place/O'Bri ... 8584?hl=en

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

Wow send that tanker truck over here, with his gas at less than $3/gallon  https://www.google.com/maps/@42.0660679 ... 6656?hl=en

https://www.google.com/maps/@42.0660679 ... 6656?hl=en

Once Rick gets a bigger blade for his saw, he'll be able to come over with his Major and cut up some of those trees for you

It's great to have a nosey round other peoples' neighbourhoods, thanks for posting your location!

https://www.google.co.uk/maps/@57.57746 ... a=!3m1!1e3

Once Rick gets a bigger blade for his saw, he'll be able to come over with his Major and cut up some of those trees for you

It's great to have a nosey round other peoples' neighbourhoods, thanks for posting your location!

https://www.google.co.uk/maps/@57.57746 ... a=!3m1!1e3

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Did some Fordson majors come with no flywheel numbers on the mark? I found "TDC" at the beginning of the mark -- but no "20" and "25" like in the picture. Maybe I need to clean it some more? If I find TDC, and then count the bars to 26 that would be correct? 26 degrees from TDC? The problem is, I am by myself and have to go to the other side of the tractor to move it -- so I lose which gear notch I am at. Am I not looking correctly for the numbers (keep looking)?? Or do I need a different method? I could put some whiteout on the pully belt at the top, and move the motor until the angle of the whiteout dot on the pull measurement is at 26 degrees? What should I do? keep looking or think of something else? thanks

Re: Fordson Major Pump install issues

You should be setting at 23 degrees not 26 degrees, the engine needs to be exact not a few degrees out either side or it will not run right.

What sort of fan belt do you have? If it is a wide one the timing mark could be on the front pulley with a pointer on the dynamo bracket. You do have an early engine with the throttle through the block so it is possible that you have no timing marks on the fly wheel although if TDC is marked the other marks should be there.

http://www.fordsontractorpages.nl/pics/ ... aul_14.jpg

What sort of fan belt do you have? If it is a wide one the timing mark could be on the front pulley with a pointer on the dynamo bracket. You do have an early engine with the throttle through the block so it is possible that you have no timing marks on the fly wheel although if TDC is marked the other marks should be there.

http://www.fordsontractorpages.nl/pics/ ... aul_14.jpg

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Hi Brian,

I installed the pump and set it to 23 degrees.

I also tried the junk yard starter -- it did not fit.

I ordered this starter:

https://www.amazon.com/gp/product/B00Q8 ... dp_summary

Db Electrical Slu0002. It appears it will work with my bolt pattern. However, it has an electric solenoid. And it also does not require a relay.

When I was trying something different with the old starter, I blew up the ignition switch. Also, remember I am having charging problems with my generator/dynamo and regulator -- but I have not been able to get the tractor to start, to test the voltage across the battery to see if it is charging.

Given that I am replacing the starter with the "db electrical " Slu0002, which does not require the relay, and I need a new iginition switch, and I need a new generator, I am going to completely re-do the electrical system, starter,etc and go with an alternator. I am going to also order a Chevy Small Block one-wire alternator -- a ACDelco SI10, and just remove the generator, regulator, relay, and now blown ignition switch. They sell a Chromed version of the 105 amp alternator that self regulates for $68USD.

However it is raining again, and everything is on hold. The new starter should be here by the end of the week when the rain stops. And when I get paid again at the end of the week, I'll buy the alternator. This one here:

https://www.amazon.com/Chrome-Alternato ... tor+chrome

Has anyone tried a setup like this? I got the idea after seeing the alternator on my Ford 2n is the same alternator on my GMC 6000 20ft flatbed, and I brought it up to the mechanics, and they said my idea is a good idea. I googled it and it seemed to be a fairly common thing to upgrade to the "one wire alternator" from the chevy alternator for tractors since it self regulates.

This is the wiring diagram I am going to use: https://youtu.be/SC8dovHUB2I?t=406 (around minute 7:15 in the youtube video)

Thanks for your help everyone, I will continue to update. Hopefully with a new injector pump, new coupler, new starter, new alternator, new battery, machine shop cleaned head, and head gaskget -- I can finally get it working. So far I am $3500 in (including the $1200 I paid for the backhoe with the seized motor 'as is')

I installed the pump and set it to 23 degrees.

I also tried the junk yard starter -- it did not fit.

I ordered this starter:

https://www.amazon.com/gp/product/B00Q8 ... dp_summary

Db Electrical Slu0002. It appears it will work with my bolt pattern. However, it has an electric solenoid. And it also does not require a relay.

When I was trying something different with the old starter, I blew up the ignition switch. Also, remember I am having charging problems with my generator/dynamo and regulator -- but I have not been able to get the tractor to start, to test the voltage across the battery to see if it is charging.

Given that I am replacing the starter with the "db electrical " Slu0002, which does not require the relay, and I need a new iginition switch, and I need a new generator, I am going to completely re-do the electrical system, starter,etc and go with an alternator. I am going to also order a Chevy Small Block one-wire alternator -- a ACDelco SI10, and just remove the generator, regulator, relay, and now blown ignition switch. They sell a Chromed version of the 105 amp alternator that self regulates for $68USD.

However it is raining again, and everything is on hold. The new starter should be here by the end of the week when the rain stops. And when I get paid again at the end of the week, I'll buy the alternator. This one here:

https://www.amazon.com/Chrome-Alternato ... tor+chrome

Has anyone tried a setup like this? I got the idea after seeing the alternator on my Ford 2n is the same alternator on my GMC 6000 20ft flatbed, and I brought it up to the mechanics, and they said my idea is a good idea. I googled it and it seemed to be a fairly common thing to upgrade to the "one wire alternator" from the chevy alternator for tractors since it self regulates.

This is the wiring diagram I am going to use: https://youtu.be/SC8dovHUB2I?t=406 (around minute 7:15 in the youtube video)

Thanks for your help everyone, I will continue to update. Hopefully with a new injector pump, new coupler, new starter, new alternator, new battery, machine shop cleaned head, and head gaskget -- I can finally get it working. So far I am $3500 in (including the $1200 I paid for the backhoe with the seized motor 'as is')

-

oregondave

- Not Quite Blue Yet

- Posts: 17

- Joined: Sun Feb 07, 2016 7:42 am

Re: Fordson Major Pump install issues

Hi,

I finally got the original starter and installed it.

It spins the motor great.

But there's a lot of problems with the wiring. The wires look original or very very very old. The starter wouldn't work, and with a volt meter, I determerined the wiring is all shot. Eventually after shaking the wiring around I was able to do a positive test that the starter works.

I'm holding off using the backhoe until I can re-wire it correctly so I don't have to shake the wires around or see any more strange sparks.

My question is now about re-wiring the tractor (all of it).

What Gauge wire should I use for everything but the battery cables? I'm hoping, 12 gauge. For the battery cables, I am using 1/0 its plenty.

Is there a link to the wiring original diagram? I have the original starter instead of getting a different starter so everything is original.

When the tractors guys worked on it, they added an ignition key. But I broke it. Did the fordson come with an ignition key or push button? Do I need one? If so, which one should I get?

My fordson was modified to have the fuel pump removed, and a generic electric one installed. Where on the starter solenoid should it be connected?

There's light fixtures, but I never bothered to look if there are bulbs. What about that?

Any info would be appreciated.

I finally got the original starter and installed it.

It spins the motor great.

But there's a lot of problems with the wiring. The wires look original or very very very old. The starter wouldn't work, and with a volt meter, I determerined the wiring is all shot. Eventually after shaking the wiring around I was able to do a positive test that the starter works.

I'm holding off using the backhoe until I can re-wire it correctly so I don't have to shake the wires around or see any more strange sparks.

My question is now about re-wiring the tractor (all of it).

What Gauge wire should I use for everything but the battery cables? I'm hoping, 12 gauge. For the battery cables, I am using 1/0 its plenty.

Is there a link to the wiring original diagram? I have the original starter instead of getting a different starter so everything is original.

When the tractors guys worked on it, they added an ignition key. But I broke it. Did the fordson come with an ignition key or push button? Do I need one? If so, which one should I get?

My fordson was modified to have the fuel pump removed, and a generic electric one installed. Where on the starter solenoid should it be connected?

There's light fixtures, but I never bothered to look if there are bulbs. What about that?

Any info would be appreciated.

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Fordson Major Pump install issues

I found a wiring diagram - from your side of the Pond, so it's suitable for left-hand-drive tractors  http://www.yesterdaystractors.com/cgi-b ... n&th=19166

http://www.yesterdaystractors.com/cgi-b ... n&th=19166

The lever to the left of your instrument panel, should operate the starter - pressing it, moves the pinion into engagement with the flywheel, and at the same time activates the solenoid so that the starter gets power.

I don't see an original-style solenoid in your photos, it should be behind the air-cleaner with big cables connected to the battery and the starter. Whoever fitted the modern-style pre-engaged starter presumably removed all that. What kind of starter have you got now anyway, you mention an original one, so a lever-operated one?

Originally the ignition switch was combined with the light switch

I'll take some photos, although it may not help you any.,

The lever to the left of your instrument panel, should operate the starter - pressing it, moves the pinion into engagement with the flywheel, and at the same time activates the solenoid so that the starter gets power.

I don't see an original-style solenoid in your photos, it should be behind the air-cleaner with big cables connected to the battery and the starter. Whoever fitted the modern-style pre-engaged starter presumably removed all that. What kind of starter have you got now anyway, you mention an original one, so a lever-operated one?

Originally the ignition switch was combined with the light switch

I'll take some photos, although it may not help you any.,

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.