Problems with Super Major external hydraulics

Problems with Super Major external hydraulics

Hello to everyone I am new to the forum and located in Alberta Canada. I look forward to any and all advice available here and I understand there are numerous highly experienced users just eager to share their knowledge. I recently purchased a Fordson Super Major (serial #8D955088) and it has the usual signs of wear and tear for a 50+ year old tractor. The engine is very sound and the tires are virtually new. The tilt bucket loader takes some time to get used to but I don't expect it will be a serious learning curve. There is an issue however and I would like some advice. I've checked everywhere I can think of on the forum but my specific issue doesn't appear to have been covered. I have drained the milky oil in the differential, refilled with new and was able to lift the FEL but now it won't come down from full up position. I downloaded as many PDF files as I could find and placed them in my library as references but even these don't appear to address this problem. I think the issue is a sticking valve but I really don't know for certain and I am hoping someone can direct me to the solution. I'm just becoming familiar with the names of the various hydraulic controls so I may be a little slow but I'm sure we would all agree there is no such thing as a stupid question.

I look forward to any suggestions. Thanks Wayne

I look forward to any suggestions. Thanks Wayne

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: Problems with Super Major external hydraulics

Hi Wayne and welcome, you may find someone in your neck of the woods on the forum from time to time

What oil did you use, if it was a heavy gear oil like EP90 then it is possibly too thick, the other thing is have you inadvertently operated the valve which selects TPL or external service under the front of the seat ?? I don't have a Super these days and its a long time since I last delved into the back of the one we did have, so best leave it for someone more hands on familiar to come along

Did you find the Swedish Fordson site ? if not Major service manual (all versions in one manual) in sections, are here http://www.fordson.se/phpBB2/viewtopic.php?f=13&t=1844

HTH

Rick

What oil did you use, if it was a heavy gear oil like EP90 then it is possibly too thick, the other thing is have you inadvertently operated the valve which selects TPL or external service under the front of the seat ?? I don't have a Super these days and its a long time since I last delved into the back of the one we did have, so best leave it for someone more hands on familiar to come along

Did you find the Swedish Fordson site ? if not Major service manual (all versions in one manual) in sections, are here http://www.fordson.se/phpBB2/viewtopic.php?f=13&t=1844

HTH

Rick

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: Problems with Super Major external hydraulics

Hello Rick, thanks for the quick reply.

The oil I used is 15/40 diesel oil, new and I filled the case to the dipstick level or maybe slightly higher.

(the other thing is have you inadvertently operated the valve which selects TPL or external service under the front of the seat ??) Is the valve that you refer to the one that screws in and out? What position should it be in? As for the files you mentioned, yes I located them and saved them on my computer. I noted that they refer to the Dexta Super and I assume that is just another name for the Fordson Super Major as sold in North America? As I was searching this site I also came across a page that stated that the PTO shaft has to be engaged to operate the external hydraulics. Now that I think of it I may have disengaged the PTO so perhaps I shut off the flow to the external, does that sound right.

Wayne

The oil I used is 15/40 diesel oil, new and I filled the case to the dipstick level or maybe slightly higher.

(the other thing is have you inadvertently operated the valve which selects TPL or external service under the front of the seat ??) Is the valve that you refer to the one that screws in and out? What position should it be in? As for the files you mentioned, yes I located them and saved them on my computer. I noted that they refer to the Dexta Super and I assume that is just another name for the Fordson Super Major as sold in North America? As I was searching this site I also came across a page that stated that the PTO shaft has to be engaged to operate the external hydraulics. Now that I think of it I may have disengaged the PTO so perhaps I shut off the flow to the external, does that sound right.

Wayne

Re: Problems with Super Major external hydraulics

If the loader is stuck up in the air it could be one of many little problems.

1. PTO has to be engaged to lift the loader but it should come down under its own weight.

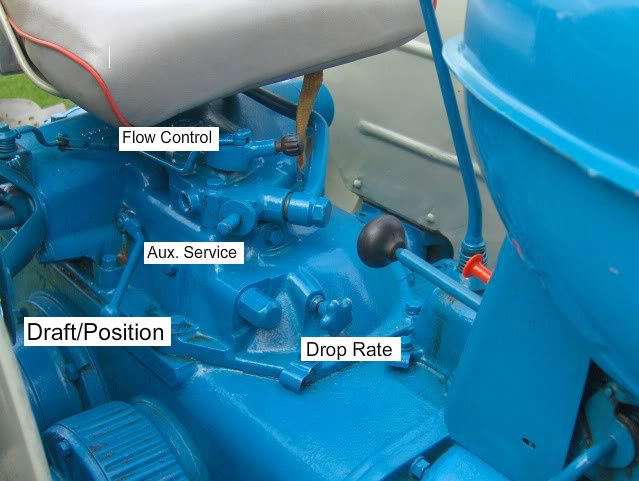

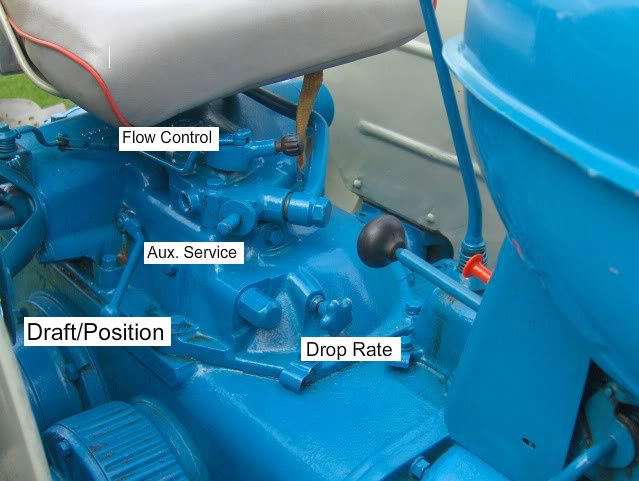

2. Auxiliary Service Selector should be pulled out. This diverts the oil away from the lift arms and to your loader.

3. The small metal lever on the lift housing should be pointing upwards not horizontal.

4. The Main Control Lever should be at the bottom of the quadrant to lower the loader.

5. Is there a tap on the loader pipework?

6. BE CAREFUL IT COULD DROP VERY QUICKLY WHEN YOU CLEAR THE PROBLEM.

7. What sort of pipe connections do you have? Some quick couplers can fail and block the oil flow.

The Dexta, Super Dexta are not the same as the Major and Super Major, they are much smaller. That is why I hate certain manuals that mix the two types of tractor. Majors and Super Majors were known as the Ford 5000 over there but not to be confused by the Ford 5000 from 1965 which waqs a different tractor all together.

Start checking the points I have raised, the problem could still be internal in the lift. Do your lift arms go up and down with the Auxiliary Service Valve pushed in?

1. PTO has to be engaged to lift the loader but it should come down under its own weight.

2. Auxiliary Service Selector should be pulled out. This diverts the oil away from the lift arms and to your loader.

3. The small metal lever on the lift housing should be pointing upwards not horizontal.

4. The Main Control Lever should be at the bottom of the quadrant to lower the loader.

5. Is there a tap on the loader pipework?

6. BE CAREFUL IT COULD DROP VERY QUICKLY WHEN YOU CLEAR THE PROBLEM.

7. What sort of pipe connections do you have? Some quick couplers can fail and block the oil flow.

The Dexta, Super Dexta are not the same as the Major and Super Major, they are much smaller. That is why I hate certain manuals that mix the two types of tractor. Majors and Super Majors were known as the Ford 5000 over there but not to be confused by the Ford 5000 from 1965 which waqs a different tractor all together.

Start checking the points I have raised, the problem could still be internal in the lift. Do your lift arms go up and down with the Auxiliary Service Valve pushed in?

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: Problems with Super Major external hydraulics

Brian, I appreciate your reply and will address the issues you mention. The PTO, auxiliary service selector and lever on the quadrant are simple corrections I will try immediately. I have noticed no tap on the leader anywhere and by tap I assume you mean like a shut-off valve? There are two issues that causes me concern. There is a diverter valve that looks "after market" mounted right on the front of the flow selector housing which diverts the flow from the loader to the rear external connection that is plugged off I assume for some other application, a log splitter maybe. The arm on this "diverter" is quite floppy and does not seem to have any resistance when manipulated. Maybe I'll see what happens when I loosen the fitting there. The other lever you mentioned doesn't seem to do anything at all as it falls straight down under its own weight and the horizontal shaft it is attached to can be rotated (when I removed the selector arm) without any effect on the hydraulics at all. From what I've read this does not appear to be good. I will attempt to send a photo if I can and I'm certain it will give you a better idea, if you don't mind another response. I just attempted to load a photo and it seems I will have to do more research to be able to do so.

Thanks again, Wayne

Thanks again, Wayne

Re: Problems with Super Major external hydraulics

You need to load your pictures to something like Photobucket then add the IMG url in your post. On Photobucket you just click on the url and it loads automatically and will appear when you paste it in the post.

There are many valves that have been put on these tractors but some have the wrong porting and will only allow you to work the loader. This is true if the valve is designed for the later tractors.

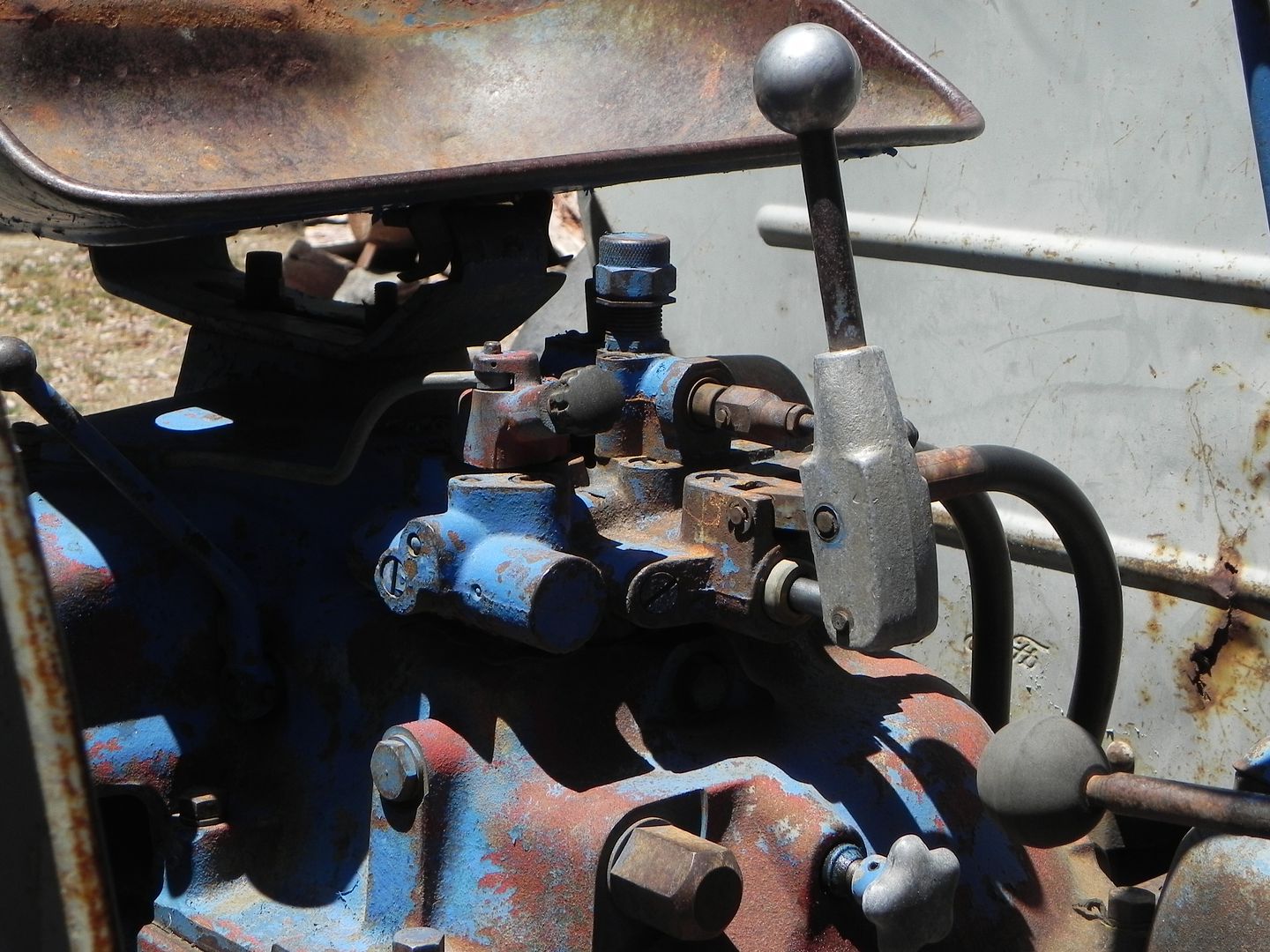

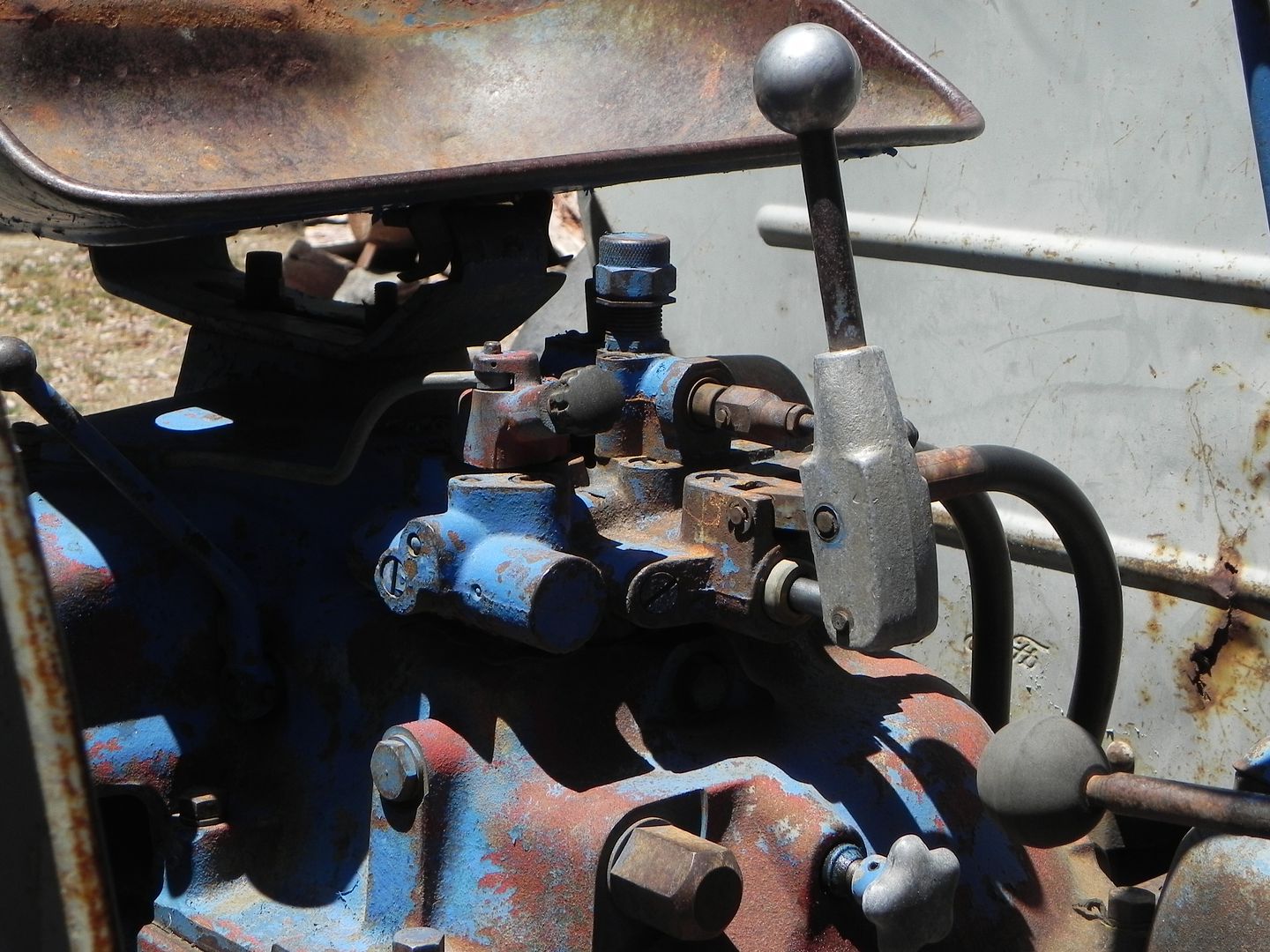

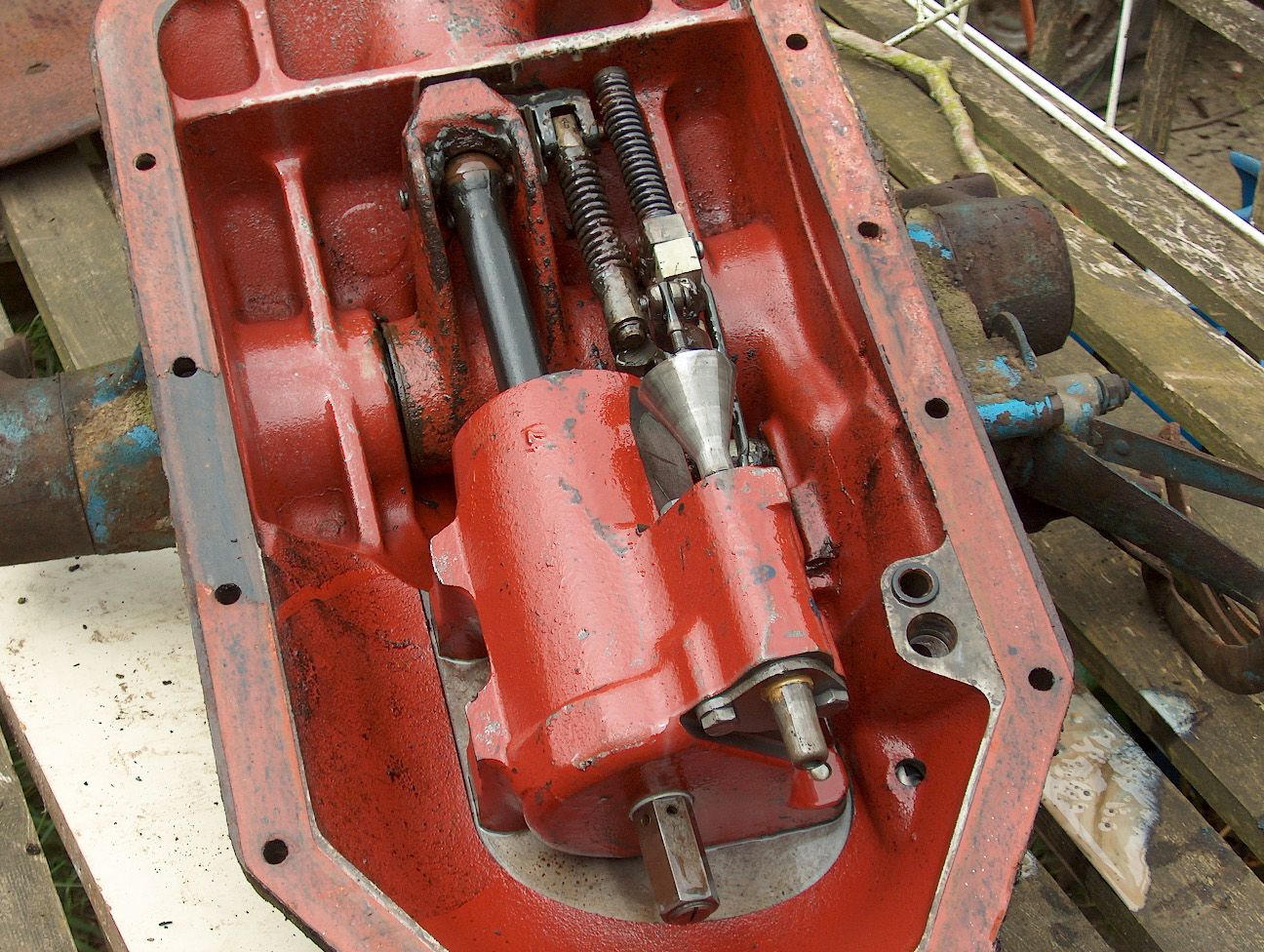

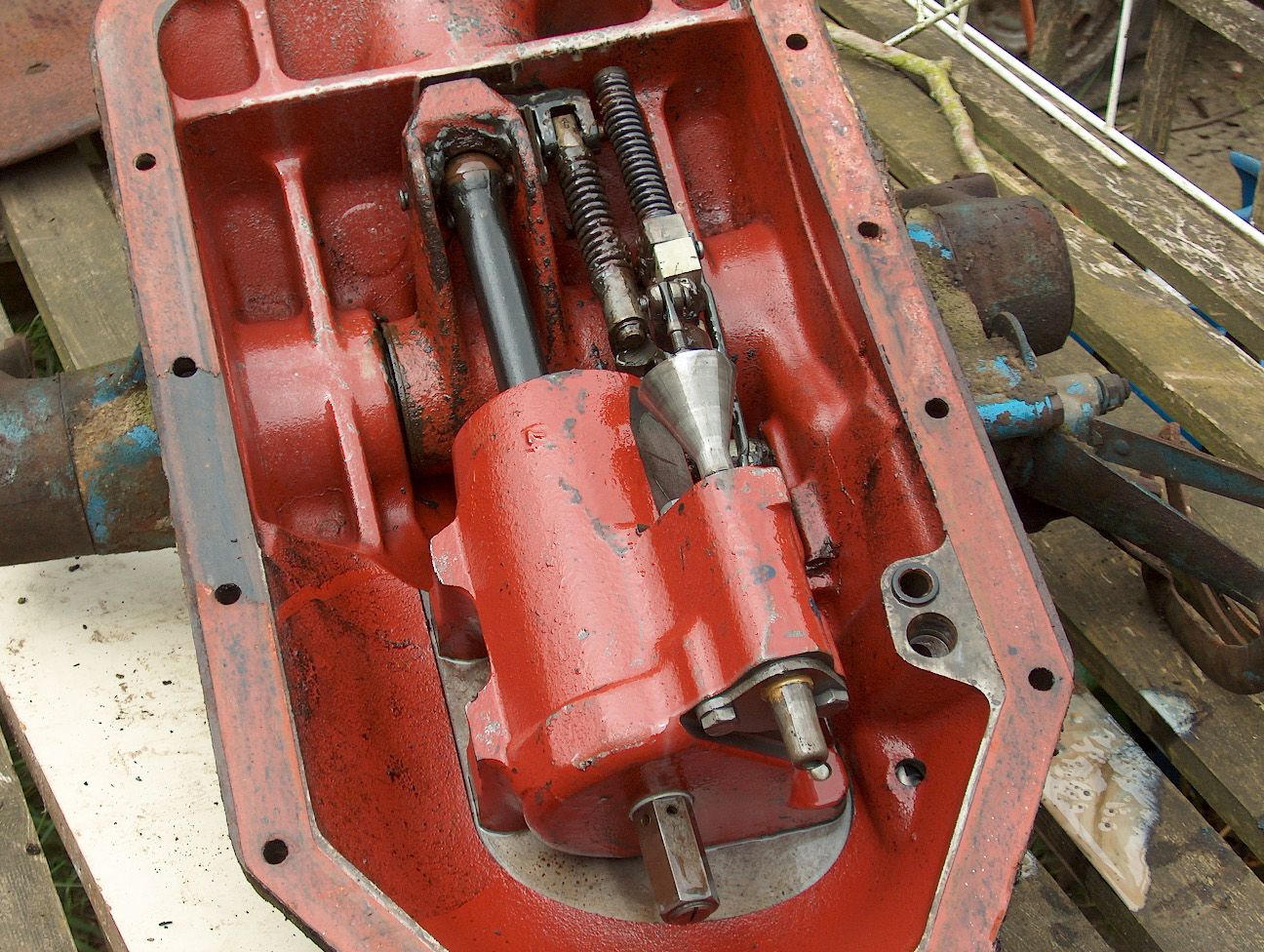

This is what it looked like before butchery.

There are many valves that have been put on these tractors but some have the wrong porting and will only allow you to work the loader. This is true if the valve is designed for the later tractors.

This is what it looked like before butchery.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: Problems with Super Major external hydraulics

[URL=http://s1221.photobucket.com/user/wdeni ... 0.jpg.html] [/URL ]

[/URL ]

Brian I hope the image shows up in my post. But I tried to operate the hydraulics without positive results. I made certain the PTO was engaged and the auxiliary selector was pulled out and the main control was in the full down position. The draft position lever was placed in the up position but as I mentioned it easily falls straight down under its own weight as there is no resistance whatsoever in any position. Is it disconnected internally somehow? My photo clearly shows the "diverter" valve I mentioned but this too has no resistance when the handle is rotated. The handle I mentioned is under the square valve in the photo and can't be seen here. Yes the lift arms go up and down with the Auxiliary Service Valve pushed in but will only remain in that position when I pull the auxiliary selector out or the arms will drop under their own weight. What do you think with this new information?

Thanks, Wayne

[/URL ]

[/URL ]Brian I hope the image shows up in my post. But I tried to operate the hydraulics without positive results. I made certain the PTO was engaged and the auxiliary selector was pulled out and the main control was in the full down position. The draft position lever was placed in the up position but as I mentioned it easily falls straight down under its own weight as there is no resistance whatsoever in any position. Is it disconnected internally somehow? My photo clearly shows the "diverter" valve I mentioned but this too has no resistance when the handle is rotated. The handle I mentioned is under the square valve in the photo and can't be seen here. Yes the lift arms go up and down with the Auxiliary Service Valve pushed in but will only remain in that position when I pull the auxiliary selector out or the arms will drop under their own weight. What do you think with this new information?

Thanks, Wayne

Re: Problems with Super Major external hydraulics

You have a very simple system there, pull the ASV = external oil, push it back in = lift arms. The fact that your lift arms drop when the ASV is pushed in and will not hold up means you have a major leak on the control circuit. If they hold with the ASV pulled out, that means the piston and seal in the ram cylinder are OK, but I would change them anyway.

First remove the Auxiliary Service Chest from the top of the housing and check "O" rings under it.

If they are all OK then the whole top has to come off to get to the linkage inside. This is very heavy and you will need some form of lifting device. Also watch out for the two studs and nuts under the lift arms, they can get missed in the excitement.

Once you have the top off post as many pictures as you can.

This is what you have when you get the top off. DO NOT LOOSE THE PARTS THAT LOOK LIKE A BROKEN SPRING WASHER FROM AROUND THE PRESSURE PIPE. They are very important and ireplaceable.

First remove the Auxiliary Service Chest from the top of the housing and check "O" rings under it.

If they are all OK then the whole top has to come off to get to the linkage inside. This is very heavy and you will need some form of lifting device. Also watch out for the two studs and nuts under the lift arms, they can get missed in the excitement.

Once you have the top off post as many pictures as you can.

This is what you have when you get the top off. DO NOT LOOSE THE PARTS THAT LOOK LIKE A BROKEN SPRING WASHER FROM AROUND THE PRESSURE PIPE. They are very important and ireplaceable.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: Problems with Super Major external hydraulics

Brian,

I thought I would do some further checking before I remove and examine the Auxiliary service "chest" (new word for me) and look at the "O" rings. As you know here in Alberta Canada it can get chilly and the oil in the rear end gets rather thick. As the temp has dropped to well below freezing I decided to drain some of the oil to have a look and it came out like thick honey. I suspect this may be having a negative effect on the hydraulics so I will have to thin the oil or use a lighter grade I think. After running the engine for a while I will see if this allows me to drop the loader. Do you have any idea why the draft arm has no tension and will not stay in the up position? How does it connect on the inside? I believe you stated that this arm has to be in the "up" position for the Auxiliary system to work.

Wayne

I thought I would do some further checking before I remove and examine the Auxiliary service "chest" (new word for me) and look at the "O" rings. As you know here in Alberta Canada it can get chilly and the oil in the rear end gets rather thick. As the temp has dropped to well below freezing I decided to drain some of the oil to have a look and it came out like thick honey. I suspect this may be having a negative effect on the hydraulics so I will have to thin the oil or use a lighter grade I think. After running the engine for a while I will see if this allows me to drop the loader. Do you have any idea why the draft arm has no tension and will not stay in the up position? How does it connect on the inside? I believe you stated that this arm has to be in the "up" position for the Auxiliary system to work.

Wayne

Re: Problems with Super Major external hydraulics

Brian,

I just had a bright thought and decided to disconnect the hydraulic lines from the loader's cylinders and the loader wouldn't drop. I had to put a come-along (you may have another name for it, similar to a hand winch) to pull the loader down and it released and dropped slowly on its own. Earlier when I raised the loader just to check how high it would raise, apparently it locked in that position and would not come back down under its own weight. After my happy dance (don't tell me you've never done that, lol) I tried the hydraulics for the loader and they worked but would still not stay up on their own unless the auxiliary valve was pushed in so I guess the "O" rings will still have to be checked. I would still like to know why the draught arm is so floppy though. Because its so cold out and Christmas I won't be tackling the rings for a bit. Any thoughts on why the loader locks like that?

Wayne

I just had a bright thought and decided to disconnect the hydraulic lines from the loader's cylinders and the loader wouldn't drop. I had to put a come-along (you may have another name for it, similar to a hand winch) to pull the loader down and it released and dropped slowly on its own. Earlier when I raised the loader just to check how high it would raise, apparently it locked in that position and would not come back down under its own weight. After my happy dance (don't tell me you've never done that, lol) I tried the hydraulics for the loader and they worked but would still not stay up on their own unless the auxiliary valve was pushed in so I guess the "O" rings will still have to be checked. I would still like to know why the draught arm is so floppy though. Because its so cold out and Christmas I won't be tackling the rings for a bit. Any thoughts on why the loader locks like that?

Wayne

Re: Problems with Super Major external hydraulics

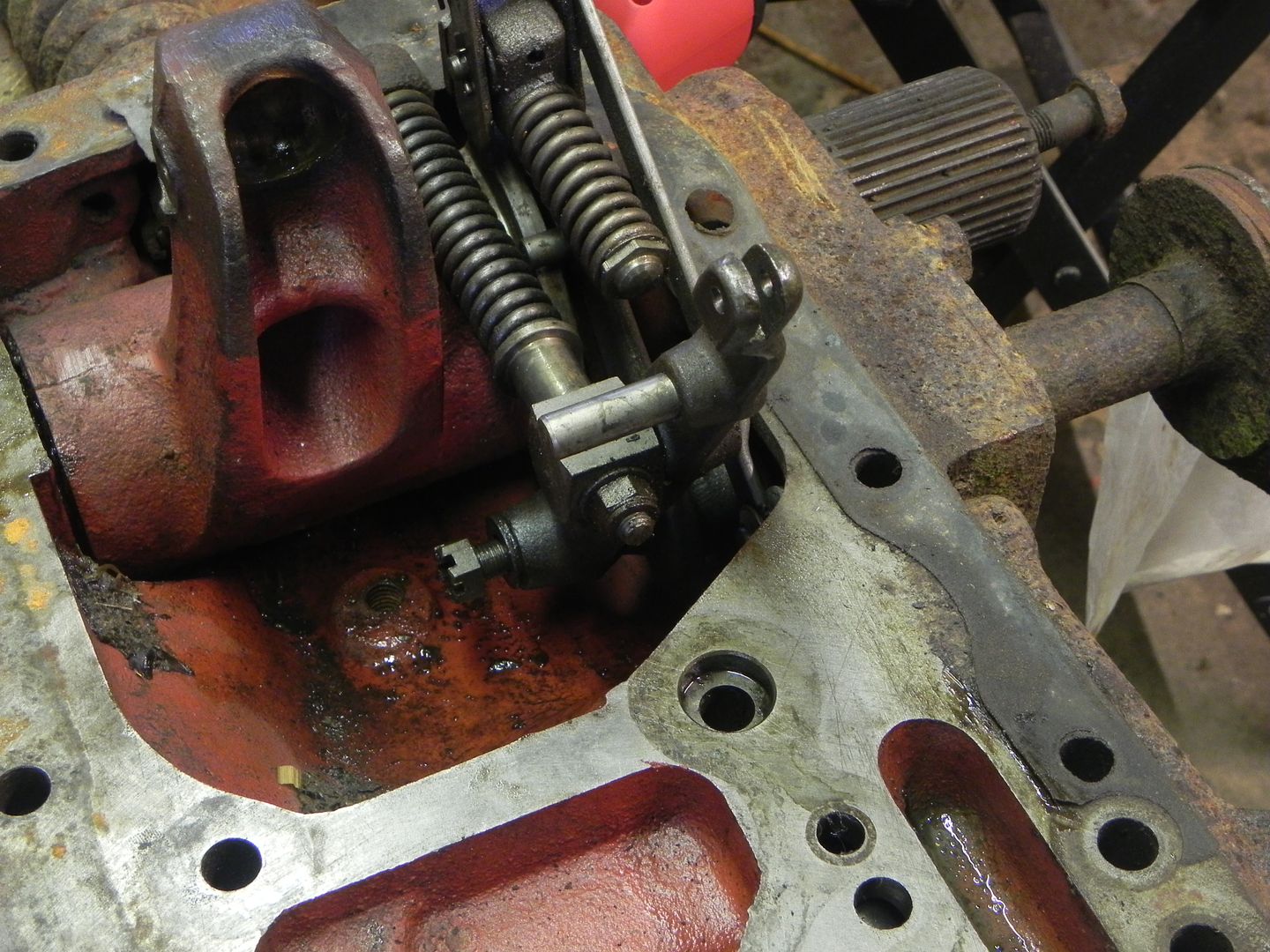

Its not quite the same as this is from a Dexta but you can just make out the flat link that comes from your handle and goes up to the springs. If the pins drop out of this or if it has been taken out for some reason, it will not change the springs and links to Draft or Position.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

blackbob

- True Blue

- Posts: 290

- Joined: Sat Jul 30, 2016 4:00 pm

- Location: Turriff, Aberdeenshire, Scotland

Re: Problems with Super Major external hydraulics

So maybe you have a problem with one of the loader rams, bent or somehow sticking at full extension, so the loader won't come down on its own? What happens if you try to lift something heavy, does the loader drop with weight on it?

We had something similar when using the grey Fergie with loader, and strong stabilisers (not pick-up-hitch) on the back into the top-link bracket - but Fergie hydraulics are much different to Major ones so I wouldn't make any further comparison

We had something similar when using the grey Fergie with loader, and strong stabilisers (not pick-up-hitch) on the back into the top-link bracket - but Fergie hydraulics are much different to Major ones so I wouldn't make any further comparison

1440276 - 1957 - working

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

1335674 - err - one day..

Claeys combine M103 - 1963 703129 - working

Ford 7710 2wd, 1983 - working

The Fordson Tractor Pages. Built to be relied on.

Re: Problems with Super Major external hydraulics

Hello Brian,

I was able to get the loader to come down as I mention above in my last reply. So yes something caused it to stick but I have to say that I extended it to max height and I don't think anyone would find that necessary in real world use.....I won't be doing that again for sure.

Re: the "flat link" you mentioned, is it the flat bar sitting on edge next to the shorter spring? Its obvious that the entire cover has to come off to access that part and I won't be doing any plowing that would require its use. Maybe if I do decide to go after the major leakage you mention then I would be dealing with it then. I any case let me extend my best wishes to you and your family this Christmas and perhaps we can communicate further in the new year.

Blessings, Wayne.

I was able to get the loader to come down as I mention above in my last reply. So yes something caused it to stick but I have to say that I extended it to max height and I don't think anyone would find that necessary in real world use.....I won't be doing that again for sure.

Re: the "flat link" you mentioned, is it the flat bar sitting on edge next to the shorter spring? Its obvious that the entire cover has to come off to access that part and I won't be doing any plowing that would require its use. Maybe if I do decide to go after the major leakage you mention then I would be dealing with it then. I any case let me extend my best wishes to you and your family this Christmas and perhaps we can communicate further in the new year.

Blessings, Wayne.

Re: Problems with Super Major external hydraulics

Thanks for your Good Wishes Wayne and may we say the same to you.

There is a slightly complicate reason why the tractor has to be set in Draft Control when using things like a loader. In Draft the only way that the main control lever can be overidden is by pressure or tension on the top link. This can be prevented by using two pins in the rocker bracket to lock it.

In Position Control however the lift can overide the main quadrant lever easily when using implements on the Auxiliary Service Port causing rather embarrassing and potentially fatal consequences. In Position Control the position of the lift arms, via the linkage, control the lift control valve. If the lift arms drop, the control valve moves into the "Raise" cycle trying to bring them back to the position the control lever is set at. But you have diverted the oil away from the ram cylinder and to the externally connected loader or tipping trailer by pulling out the Auxiliary Control Valve.

The oil is therefore lifting the implement and, no mater where you place the control lever the implement will continue to raise. The only way to stop it is to kill the engine or knock the Auxiliary Service Valve into ram cylinder mode.

It was a common problem back in the day when operators did not read the drivers handbook! Been there, done that, helped clear loads of corn and sugar beet off the Norfolk roads.

And Oooops!!!!!

Done it myself with a load of pantomime scenery in the middle of Swaffham Market Place.

Done it myself with a load of pantomime scenery in the middle of Swaffham Market Place.

So, to avoid problems the selector lever must always be in Draft Control when using implements on the Auxiliary Service Port. If you have a linkage fault, I would suspect that it has defaulted to Position Control and could possibly have a bearing on your original fault.

There is a slightly complicate reason why the tractor has to be set in Draft Control when using things like a loader. In Draft the only way that the main control lever can be overidden is by pressure or tension on the top link. This can be prevented by using two pins in the rocker bracket to lock it.

In Position Control however the lift can overide the main quadrant lever easily when using implements on the Auxiliary Service Port causing rather embarrassing and potentially fatal consequences. In Position Control the position of the lift arms, via the linkage, control the lift control valve. If the lift arms drop, the control valve moves into the "Raise" cycle trying to bring them back to the position the control lever is set at. But you have diverted the oil away from the ram cylinder and to the externally connected loader or tipping trailer by pulling out the Auxiliary Control Valve.

The oil is therefore lifting the implement and, no mater where you place the control lever the implement will continue to raise. The only way to stop it is to kill the engine or knock the Auxiliary Service Valve into ram cylinder mode.

It was a common problem back in the day when operators did not read the drivers handbook! Been there, done that, helped clear loads of corn and sugar beet off the Norfolk roads.

And Oooops!!!!!

So, to avoid problems the selector lever must always be in Draft Control when using implements on the Auxiliary Service Port. If you have a linkage fault, I would suspect that it has defaulted to Position Control and could possibly have a bearing on your original fault.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: Problems with Super Major external hydraulics

Brian,

In an attempt to decipher the terminology you use (my limitation not yours) I believe the bottom line is to re-attach the draft arm as well as check for the major leak you referenced earlier. This would require the removal and servicing of the whole hydraulic cover if I'm correct? That said, this operation may have to wait for a warmer day and a full day at that. In the meantime I will see what I can do about the Auxiliary control "block" (my terminology) and check the "O" rings which should be a relatively easy repair....we'll see.

Wayne

In an attempt to decipher the terminology you use (my limitation not yours) I believe the bottom line is to re-attach the draft arm as well as check for the major leak you referenced earlier. This would require the removal and servicing of the whole hydraulic cover if I'm correct? That said, this operation may have to wait for a warmer day and a full day at that. In the meantime I will see what I can do about the Auxiliary control "block" (my terminology) and check the "O" rings which should be a relatively easy repair....we'll see.

Wayne

Re: Problems with Super Major external hydraulics

My Fordson Super Major 5000 has a different type valve body than the ones i can find pictures of, and I can not get the lift to work. I have had the top off 4 times the piston goes in and out the control valve seems to work fine the internal parts are all working I get oil to the plug on the right side and up into the top valve but I think it is just circulating. I have no manual and am not sure where the valves are supposed to be. there is a twist valve on the front of the top cover and two valves on the valve body th front of the seat but it does not look like the ones I have seen pictures of. I don't know if it is a loader type attachment or what. Can anyone help with suggestions.

Thanks, Garry ^Space^

Thanks, Garry ^Space^