Page 2 of 2

Re: TS 59 J

Posted: Mon Sep 24, 2012 8:55 am

by tom lad

ploughs all back together

had a few hours practise / play

entered local match last sunday , which was fun , it seems traditional for it to rain alot for that match

basically working well , plough was set to 12" tractor rears 56" centers , as im struggleing to turn furrows propperly , sitting on edge abit , i think ill drop to 10" furrows , i'm told the yls do better on 10" and most other people r on 10 . i'll then have to narrow my bloomin rear track again wont i ? 52" ?

never used a implement with a depth wheel be for , so i left it in possition control and set quadrant as low as poss. ? seemes to work .

add photos wen i get a mo.

i can now see why they use the screw adjuster for the sliding cross shaft that i dissagreed with , might make one

as ground around here is now WET prob. winter conditions, with local farmer not even finished harvest , let alone the autumn ploughing /sowing might not get to play anymore for a while .

Re: TS 59 J

Posted: Tue Sep 03, 2013 8:52 am

by tom lad

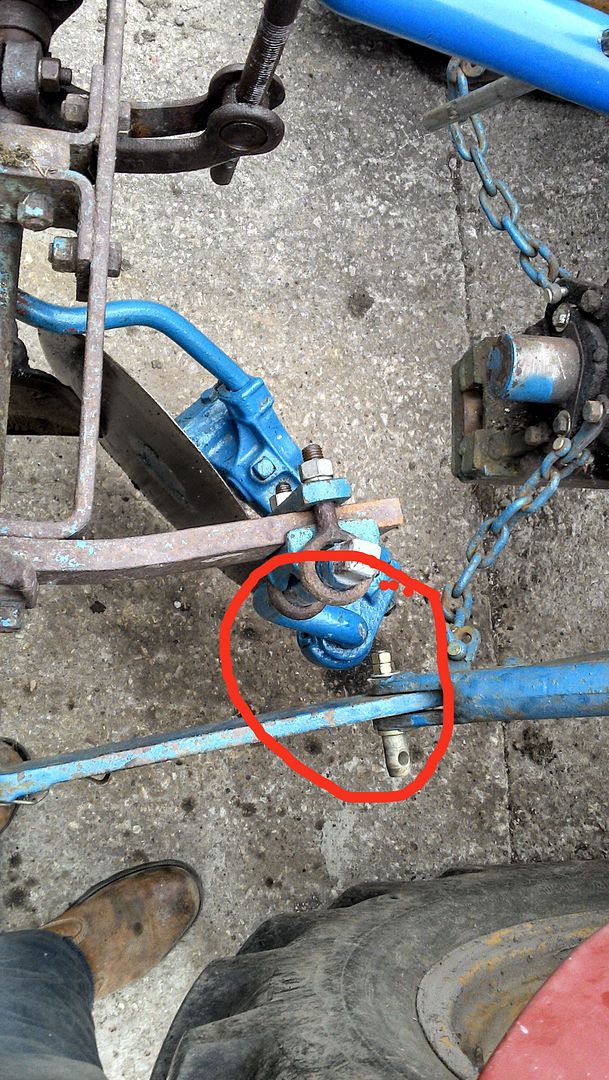

cant decide how best to assemble the legs for the 10 " width , ie which side to bolt them on ?

the way I was advised , needing a 1" spacer puts the front disc coulter arm too near my right hand link arm . altho that way I may get away with the 56" wheal setting .

manual don't show it done that way .

photo needed

I think

Re: TS 59 J

Posted: Tue Sep 03, 2013 9:21 am

by tom lad

Re: TS 59 J

Posted: Tue Sep 03, 2013 9:00 pm

by henk

Tom,

Maybe this will help

http://people.zeelandnet.nl/hmdetroije/ ... index.html

Mine is set on 12 inch.

I can't see how wide the frame is, but it should messure from left inside to right outside 12 inch. Both legs on the inside should than be 10 inch, Both legs on the outside should give 14 inch.

When your sharepoints are not the same wide, something is bended.

The bar for the diskcoulter is bended so it can give you trouble.

Re: TS 59 J

Posted: Tue Sep 03, 2013 11:33 pm

by tom lad

thanx for the link , very interesting .

I was using my yl 183 bodies set at 12 " but it doesn't fully turn the furrow well , I have been advised be for and since that yl s are best at 10 " so that's what i'm going for .

in a farming sence ploughing a big field only turning 20" a pass seems slow going but that's what they did I guess.

my neighbours 5 f lemkin reversible, I think is set on 14" , poss. 16" not sure , 70 " a pass and travels faster . interesting .

is that a prop on the rear leg , mine had a odd piece of angled rusty metal on the back leg near the long landslide , badly worn , I haven't replaced it yet . it hinged down .

Re: TS 59 J

Posted: Sun Sep 08, 2013 11:52 am

by henk

That's the support of the rear moulboard. It has an eye where the support rod for the landslide is held in.

Re: TS 59 J

Posted: Sun Sep 08, 2013 1:23 pm

by tom lad

ok I read some were a comment about a hinged prop that if the plough was lowered , quick it propped the shares of the floor so u didn't snap anything , it hinged rearward when u ploughed forward .

if I understood it all correctly

never seen one tho.

not mentioned in my repro.hand book

Re: TS 59 J

Posted: Sun Sep 08, 2013 4:44 pm

by henk

I know what you mean. I'll try to take a picture of it next week.

Re: TS 59 J

Posted: Mon Sep 09, 2013 8:46 am

by tom lad

Re: TS 59 J

Posted: Sun Sep 15, 2013 1:29 pm

by henk

Sorry Tom, there was no one with that device on there plough at the match.

Re: TS 59 J

Posted: Mon Sep 16, 2013 7:57 am

by tom lad

no prob m8

I entered the local match yesterday ,my third year it is held on the farm next door to mine .

I never thought to look for the bracket on the other ploughs.

to my shock I came second in my class , vintage mounted .

the chap that won has won the last 2, I think , a nice guy.

I made a total mess of my finish , think I will have to make that screw adjuster, I also need the left hand disc coulter .

it rained again for most of the day ,as it has for the last 3 years

it does ruin everything.

good day out , I learned more about my plough through help.

my darling filmed a bit for me , in the rain sorry,

http://youtu.be/1Lj453PzJzA

http://youtu.be/332kUUlUrqA

Re: TS 59 J

Posted: Tue Aug 19, 2014 8:51 am

by tom lad

must be ploughing time again

left hand disc advise please gentlemen

I need a left hand disc for me plough

I have a disc / bearing that will prob. do , but no L H arm

anyone have one for sale ?

I think match lads just loosen the collar and swap the arm ass. ? rather than the whole stem

I have some more R H arms , is it simply chop off and re weld , is the socket / pivot the same or L H / R H ?

advice please

I know / believe west lake will prob have it all for a fee , is one better to bite the bullet than mess about in the workshop when I could be ploughing ???????

Re: TS 59 J

Posted: Tue Aug 19, 2014 10:44 pm

by henk

Tom,

I made one myself. Just get it in half, turn it around and weld it back together. Havend used it so far. Still working on the opening and start. The end furrow is still a difficult part for me.

Made some adjustments tonight, and hope I can make some hours before the match on 9 september.

Re: TS 59 J

Posted: Tue Aug 19, 2014 11:36 pm

by tom lad

Thanks henk mig welded. ??

My last finish looked more like a canal

I'd forgotten to graduly shallow up

It was pouring down rain in my defence

All the best mate

Re: TS 59 J

Posted: Wed Aug 20, 2014 8:01 am

by henk

I used welding electrodes.

Do you have any troubles with your dept wheel during the second last run?

Mine is running behind the tractor wheel on the bottum of the furrow and can't get deep enough to make a un deep furrow for the last run.

Re: TS 59 J

Posted: Wed Aug 20, 2014 2:54 pm

by tom lad

I think I used the tractor depth control on the second to last run

I can get my wheel a long way down ./shallow

Wheel will touch the floor when un hitched. If that makes sense.

Stops it falling over.

Re: TS 59 J

Posted: Sun Sep 21, 2014 8:07 pm

by henk

Found out that the settings of my plough was not right. The beams were on the wrong side from the beginning. Made the plough go heave trough the soil and not cutting clean. Now it works much better, but it ment that the hole setup from dept wheel and toplink for the opening furrow and the crown was different.

Looking from behind the plough:

Ploughing 10": the plough beams need to be on the inside of the frame and the frame needs to be on the right side of the cross shaft.

Ploughing 14": the plough beams need to be on the outside of the frame and the frame needs to be on the left side of the cross shaft.

Ploughing 12": the front plough beam need to be on the inside of the frame. The rear plough beam needs to be on the outside of the frame and the frame needs to be on the midlle of the cross shaft.

The dept wheel will run much better next to the rear wheel of the tractor and run on the unploughed land in the second last run.

Sorry the text is in Dutch.

Re: TS 59 J

Posted: Mon Oct 06, 2014 3:57 pm

by tom lad

glad you got it sorted

looks a bit like the pictures in my ransomes booklet , but mines in English .

I bought a second hand , left hand disc for west lake in the end , im glad I did I'm happy with it , came with new disc un bearings ok , so should see me out

I'm gonna make the winder for the cross shaft + the adjustable depth wheel , if/ when , I can , or at least that is the plan.

all the best