Page 8 of 16

Posted: Sun Aug 30, 2009 8:43 pm

by Pascal

Hi guys,

Yesterday I managed to get the liners into the engine.

It went great thanks to the pictures and advices of the members of this board! Thank You!

The crankshaft has little rust on it. It fell on it, when I removed the liners. Unfortunatly I didn't removed it immediately. No I have some trouble cleaning the crankshaft. Anybody any advices?

The first piston is in. I'll try to do the rest this week.

I'll keep you updated.

Posted: Mon Aug 31, 2009 1:59 am

by JC

Hi Pascal,

It looks like there may be some rust pits in your crankshaft, but its hard to tell from a picture. If its just rust flakes that fell on there and stuck, I would spray some WD-40 on it and try to wipe it off with a rag. If it doesn't come off, then use some fine emery cloth to polish the bearing surfaces. Have you measured the diameter of the bearing journals?

Do you have any pictures of your engine block with the liners out of it? It looks like it should be too old to use the 2 o-ring liners.

Posted: Mon Aug 31, 2009 8:59 am

by Pascal

Hi JC,

Luckily there are no rust pits in my crankshaft. When I removed the pistons, the crankshaft was completely without rust.

I'll try with WD40. Thank you for your advice!

I'll keep you updated.

I have some pictures of the engine, but not with me right now.

I thought (too) that I had the older version and needed the liners with one o-ring. But I needed 2 o-rings.

The head is from 1959 and the engine block is from 1961. Perhaps one of the first blocks with 2 o-rings?

The reason I have a vacuum governor instead of the mechanical one, is perhaps because of the vacuumbrakes of the truck (where the engine is coming from).

I believe, that only the vacuum governor had 2 outputs: one for the distribution and one for the vacuum brakes.

Posted: Mon Aug 31, 2009 9:41 am

by Grani

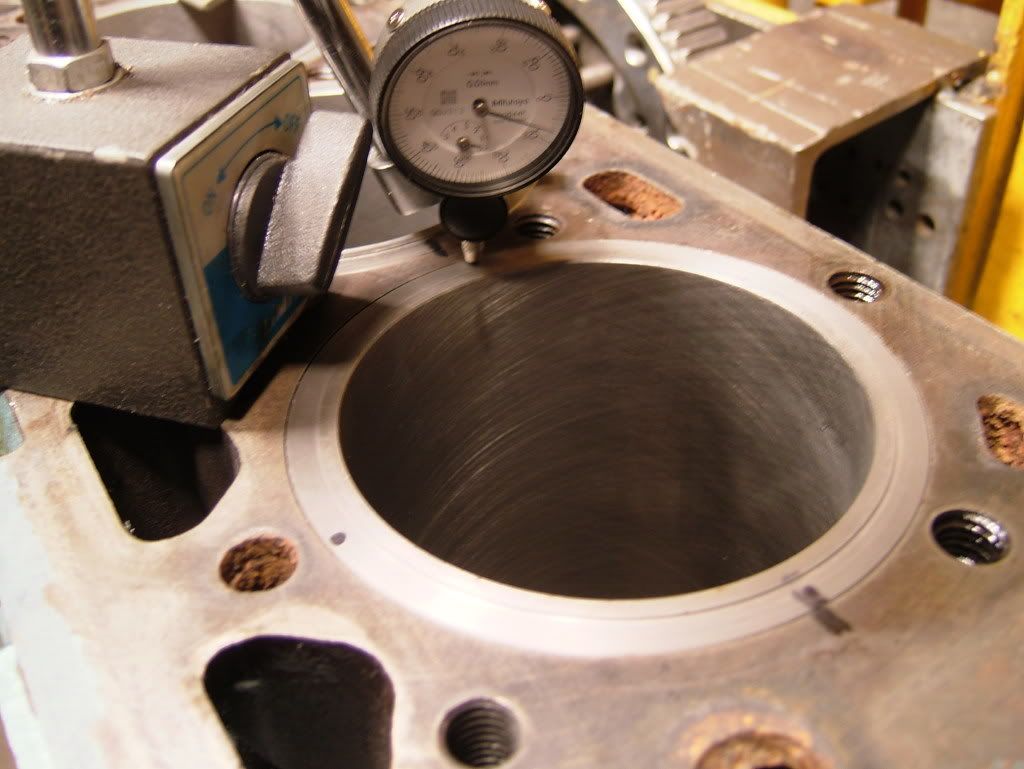

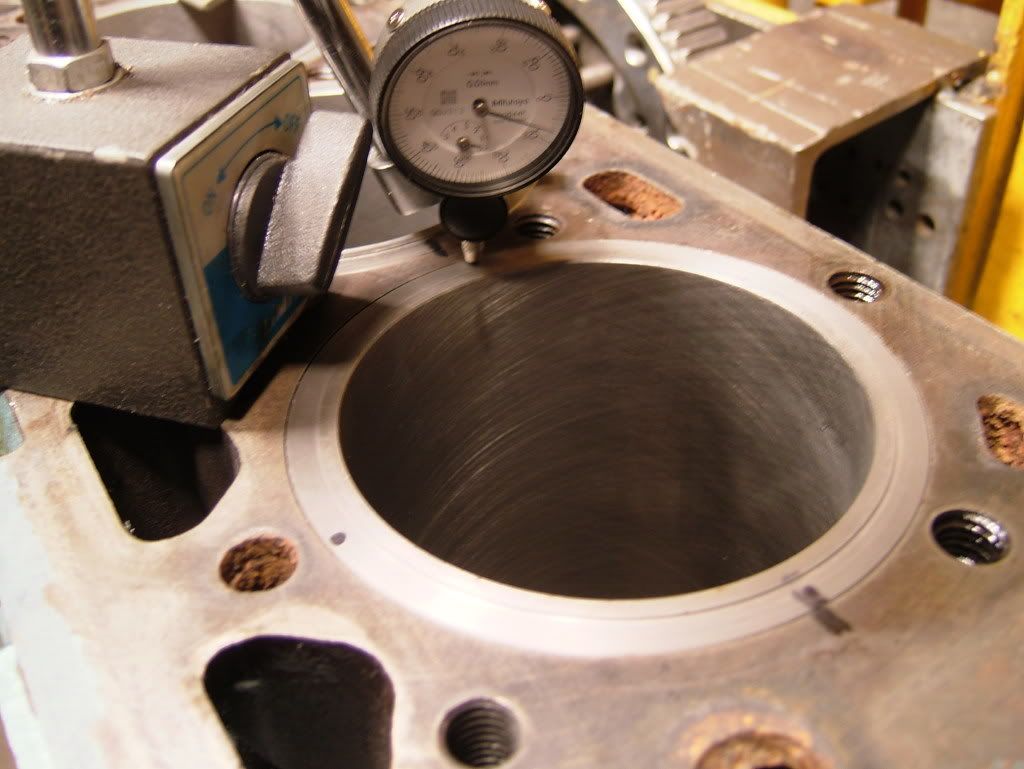

Hard to tell from the picture but the liners seems to protrude more than 0,1mm. I hope I am wrong about it.

The Minimec has shaft drive output at the rear too.

Posted: Mon Aug 31, 2009 9:53 am

by Pascal

Hi Grani,

I hope you are wrong too.

but it's good, that you mention it.

When I placed the liners, the liners (the outer ring) didn't protrude. Do you perhaps have an picture of your block with the liners placed?

Posted: Mon Aug 31, 2009 10:22 am

by Grani

Shims are available only for the older liners with one O-ring, not to the new one. Turning them in the bores or changing them from one bore to another is the only way to get them to protrude whithin limits. This procedure has to be done without the O-rings and the position has to be marked so they can be placed exactly in the same place later with the O-rings. (The dots in my picture)

Posted: Mon Aug 31, 2009 2:10 pm

by Pascal

Hi Grani,

Thank you for your explanation and the picture!

Do you measure the 0,1mm from the outside or the inside (higher part) of the top of the liner?

On the picture, it looks like if the outside of your liner is a little lower than the upper part of the engine block. Or is it just an optical illusion? Or is that the way it should be?

What's the consequence if the liners are too high?

Posted: Mon Aug 31, 2009 2:32 pm

by Grani

It is the outer lower part of the liner that has to be 0,05-0,1mm higher than the surface of the block. If it is too high the gasket is not pressing the outer area with the cooling channels enough to keep it from leaking and if it´s too low the liners may move up and down in the bore and tear them and the block.

Here is a link to all you have to know about your engine repair. This is for Fordson Major but it goes for the 590 E too. This problem is explained on page 13.

http://www.fordson.se/1A_Motor_Suplemen ... 01-031.pdf

I hate to say this but if you did not take the crankshaft and camshaft out when you took the liners out, then you can not possibly keep everything clean enough for assembly. The cooling water section has to be washed and the oil grid with the blinds taken off. A wery small amount of rust or dirt can ruin the whole thing.

Posted: Thu Sep 10, 2009 6:02 am

by Mark

I've enjoyed this post from the beginning, makes we wish I had a major to go with my dexta.

Keep up the good work men!

Posted: Thu Sep 10, 2009 6:18 am

by Grani

Mark wrote:I've enjoyed this post from the beginning, makes we wish I had a major to go with my dexta.

Keep up the good work men!

I hope I have not scared him away?

Posted: Mon Sep 14, 2009 2:47 am

by Mark

I doubt that Grani, this thread is 8 pages long, you all are giving him good sound advice, that he is listening to. I'm sure he is very grateful for everyones personal experience's on engine building.

Once again this is a very informative topic.

Posted: Mon Sep 14, 2009 7:02 am

by Pascal

Hi guys,

Here a quicke update from Amsterdam.

I have been busy lately, so I haven't made much progress on the 590e.

I managed to get the pistons in. After turning the engine round (by hand) a couple of times, the engine runs smoothly.

I cleaned the coolingwatersystem quite good. I even vacuumcleaned (with permission of the missus to use the vacuumcleaner

) it. I will have to clean the crankshaft section (under the engine). I will do that, just before mounting the sump.

Grani, what do you mean with the blinds?

Thank you for all your advices!

Posted: Mon Sep 14, 2009 7:55 am

by Grani

Pascal wrote:Grani, what do you mean with the blinds?

Zorry for my bad english

I mean the plugs in the ends of the oilchannels in the block.

Posted: Mon Sep 14, 2009 9:59 am

by Pascal

Hi Grani,

Your English is good, but the problem is the lack of knowledge about engines.

Do you may be have a picture of the blinds? Perhaps I know what they are, but I am not familiar with the name?

Thank you in advance!

Posted: Mon Sep 14, 2009 11:47 am

by Grani

One is abow the oilpressure switch and the oilpressure switch itself has to be removed, then one plug is behind the flywheel and one in the front end of the same oil channel behind the front mountingplate. All the oil holes are drilled from these point and then closed with plugs. The only way to clean the holes (or oil grid) is to remove the plugs and ofcourse with the shafts removed.

Posted: Mon Sep 14, 2009 6:39 pm

by Pascal

Hi Grani,

Are these two of the plugs you mean?

Posted: Mon Sep 14, 2009 7:46 pm

by Grani

Yes they are and there are more of them. I found 8 holes of the oilgallery on just the outside of the block, some with plugs and som (like the pipe on your picture and) to the oilfilter and cylinderhead. Then there are the holes for each bearing inside the block. Every hole has to be open so that you can clean the gallery properly.

Here is a picture of an oilgallery of an other engine, but you can se the princip of the gallery.

http://www.youtube.com/watch?v=ALuFWuXlyb8

Posted: Mon Sep 14, 2009 8:55 pm

by Pascal

Wow, Grani! Thank you so much for your advices, picture and flick!

I hope to find sometime this week to find all of them.

What's the best way to clean the oilgallery? Blow air through them?

Or some kind of fluid?

Posted: Mon Sep 14, 2009 9:14 pm

by Grani

Yes use some solvent and a pipe cleaner first and then flush with water and then blow with compressed air and then look through and make sure all dirt is gone.

Posted: Tue Sep 15, 2009 6:06 am

by Pascal

Thank you for the advice!

I'll keep you updated.

Posted: Tue Sep 15, 2009 6:33 am

by JC

Hi Pascal,

I don't know if you read it, but Grani said in an earlier post, that you need to remove the crankshaft and the camshaft before you clean the oil passages. If you don't, you will push the dirt into your bearings.

Posted: Tue Sep 15, 2009 8:14 am

by Pascal

Hi JC,

Yes I have read the advice of Grani in his previous post.

I must say, that I fear a little bit to remove both shafts... mainly the camshaft

Especially because I don't have the opportunity to turn the engine up side down or to lift it quite high and remove both shafts.

Both shafts need to be removed from the lower side of the engine?

And to remove hte camshaft, the crankshaft needs to be out first?

Guess there no solution to clean both shafts, while leaving them in?

Posted: Wed Sep 16, 2009 8:00 am

by JC

Can you get someone to help you turn the engine upside down, Pascal? You should take the liners out first or use some bolts and flat washers to hold them in. Roll the engine onto something soft, so you don't damage any machined surfaces. The camshaft comes out the front.

Posted: Wed Sep 16, 2009 2:52 pm

by Pascal

Hi guys,

I guess I'll gather my courage together

and remove both shafts. Quite a big job to me.

I agree with you, that when one does something, it has to be done right.

I think, that removing the crankshaft won't be such a problem: just unbolt it. Perhaps removing the gear on the front of the engine will be a challenge?

But the camshaft looks a bit complicated to me. I guess I'll have to remove the front plate first? Does it comes out then, of do I have to remove some bolts?

Looking forward to your advices.

Posted: Wed Sep 16, 2009 3:07 pm

by Grani

Read this carefully because it has all the information you need. It is for the four cylinder engine but it goes for the six to, except for the serialnumbers.

Keep all parts in the specific order so you can be shore to get them back in the same place as before.

http://www.fordson.se/1A_Motor_Suplemen ... 01-031.pdf