From Farm Implement and Machinery Review, July, 1945:

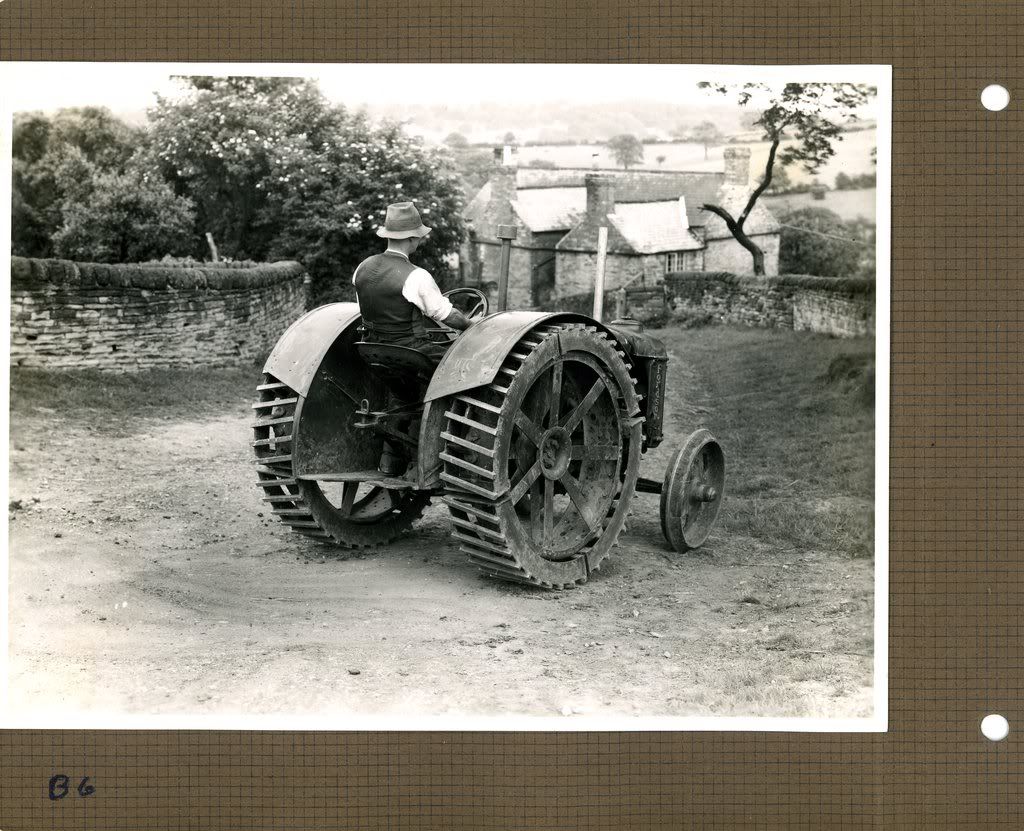

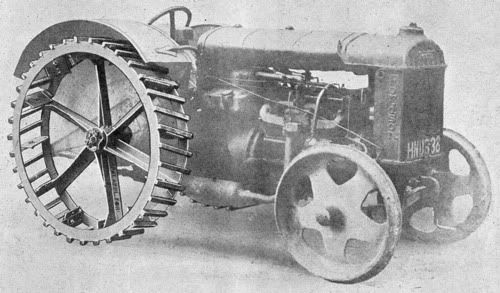

After an interval of some 12 months waiting for a licence to manufacture, Messrs. Isaac Cundey & Sons, engineers, Alfreton, Derby, announce they are in production with a new "Cundey" patent all-purpose tractor wheel. This wheel, while basically unaltered from the original one introduced to readers of THE REVIEW in May, 1943, is yet of improved construction, so it is pertinent to point out that "hundreds of pairs of these wheels are now in use in different parts of England, and," we are informed, “are giving every satisfaction,"

It may be remembered that the wheel was declared to be unique in that it can be used on hard roads without doing any damage to the surface and yet go straight into operation on cultivated land without adjustment or alteration in any way, thus eliminating the bugbear of roadband removal. The tread is claimed to be self-cleaning whatever the ground conditions, soil passing through the tread spacings and falling away to leave the good continuous grip of the crossbars quite unimpaired.

Twelve retractable spuds can be fitted to each wheeI to give maximum possible adhesion under extremely bad conditions, but all ordinary ploughing and discing can be done without such assistance. In fact, it is said that two 8in. deep furrows can be turned in this way in old grassland on heavy clay soil. When the wheel is used for harvesting, it runs over hay swaths and other crops without pinning them to the ground.

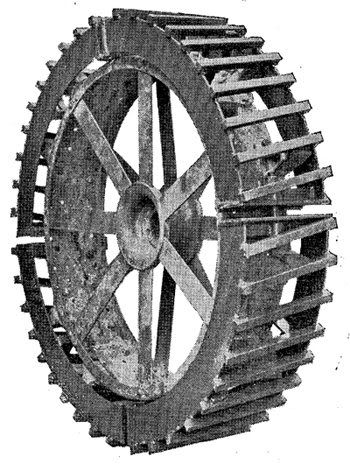

The new wheel, which like the original one is interchangeable with the standard "Fordson" rear wheel and is removed and replaced in the same way, differs mainly in spoke design, angle section material now being used instead of " I " section. This allows the spokes to lie right up against the inside ring of the rim and makes for better soil clearance. These angle section spokes are also stronger sideways than the " I " section ones. Furthermore, on the new type wheel the rims and the square tread bars have been increased in section, thereby giving greater strength and durability. The wheel is also now much heavier, and is of miid steel throughout, with full use made of electric welded fabrication; no rivets are used and the only bolts are those for attaching the retractable spuds.

Their theories sound good. How about in practice? They look to be larger than the Fordson wheel.

Any owners wish to report?

Eric