New Performance Major Rev Counter

New Performance Major Rev Counter

One item that I never managed to complete satisfactorily on the rebuild of my July 1963 NP Super Major (about 6 years ago) was the rev counter. In the collection of bits that I started with was an old AC rev counter. I sent this away to one of the available companies to be reconditioned and it was sent back, stating "beyond repair". I have since struggled to find someone to recondition my old one, find a restorable one, find a correct "new" one, or even find one in working condition at the most amazing prices on "our" ever popular auction site. So here is something for you to consider.

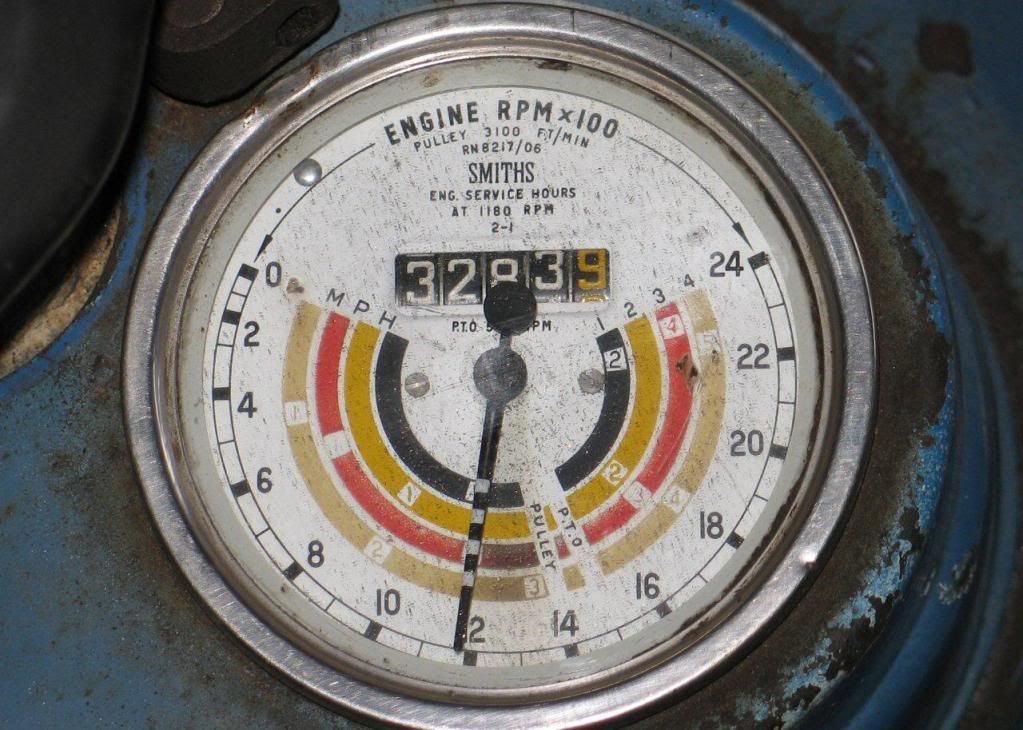

From detailed study of other NP Super Majors and older Super Majors, I understand that as the NPM had different PTO drive ratios, the rev counter is peculiar to tractors fitted with it. There appears to be two manufacturers with subtle differences between the two. The one manufactured by Smiths (and the most common) has a serial no: RN 8217/06 and I have seen ones with Serial No 8217/07. The face goes from 0 to 2,400 rpm in an anti-clockwise direction from 10 o clock to 4 o clock. Pulley speed is indicated at 1400RPM by a "bar" across the speed "rings". PTO speed is indicated at just under 1500RPM by a similar "bar".

The AC ones appear to be much rarer. Their speed "bars" are a different colour than the Smiths ones. The face goes from 0 to 2,400rpm starting at 4 o clock and going anticlockwise to 8 o clock. I have seen 2 types of marking on these AC types. One type had a "Std PTO" bar at 1200rpm, a Pulley bar at 1400rpm and a "Raised PTO" bar at 1600rpm. The other AC type just had Pulley and PTO "bars" at 1400rpm and 1500rpm respectively.

I have bought about 8 new rev counters over the last 6 years, all claiming to fit the anti-clockwise drive of the NP Super Major and despite the best efforts of the supplier, (Dunlops) they last about 4-5 months on the tractor before failing. Yes, I am aware of the anticlockwise wound cables, but it is the rubbish quality repro rev counters that fail, not the cable

Is my review of the rev counter situation (above) on NP Super Majors correct? Why did Fordsons fit 2 different makes of rev counters to NP Super Majors? (Presumably to mitigate against production hold-ups if one supplier was remiss) Was there any coherence in Fordson's production regime; Were Smiths ones fitted at first and then AC ones, or was it totally random throughout the NP Super Major production run as to which type would be fitted? Does anyone know of any instrument reconditioning company which is willing to take on a serious case (such as mine) in the UK? Finally, has anyone got a restorable Smiths one and don't want to make their fortune? Tootlepip Tim E (N Dorset)

From detailed study of other NP Super Majors and older Super Majors, I understand that as the NPM had different PTO drive ratios, the rev counter is peculiar to tractors fitted with it. There appears to be two manufacturers with subtle differences between the two. The one manufactured by Smiths (and the most common) has a serial no: RN 8217/06 and I have seen ones with Serial No 8217/07. The face goes from 0 to 2,400 rpm in an anti-clockwise direction from 10 o clock to 4 o clock. Pulley speed is indicated at 1400RPM by a "bar" across the speed "rings". PTO speed is indicated at just under 1500RPM by a similar "bar".

The AC ones appear to be much rarer. Their speed "bars" are a different colour than the Smiths ones. The face goes from 0 to 2,400rpm starting at 4 o clock and going anticlockwise to 8 o clock. I have seen 2 types of marking on these AC types. One type had a "Std PTO" bar at 1200rpm, a Pulley bar at 1400rpm and a "Raised PTO" bar at 1600rpm. The other AC type just had Pulley and PTO "bars" at 1400rpm and 1500rpm respectively.

I have bought about 8 new rev counters over the last 6 years, all claiming to fit the anti-clockwise drive of the NP Super Major and despite the best efforts of the supplier, (Dunlops) they last about 4-5 months on the tractor before failing. Yes, I am aware of the anticlockwise wound cables, but it is the rubbish quality repro rev counters that fail, not the cable

Is my review of the rev counter situation (above) on NP Super Majors correct? Why did Fordsons fit 2 different makes of rev counters to NP Super Majors? (Presumably to mitigate against production hold-ups if one supplier was remiss) Was there any coherence in Fordson's production regime; Were Smiths ones fitted at first and then AC ones, or was it totally random throughout the NP Super Major production run as to which type would be fitted? Does anyone know of any instrument reconditioning company which is willing to take on a serious case (such as mine) in the UK? Finally, has anyone got a restorable Smiths one and don't want to make their fortune? Tootlepip Tim E (N Dorset)

Re: New Performance Major Rev Counter

Speedograph-Richfield, Nottingham are the experts at fixing them. They are specialists in parts/servicing for Smiths Instruments.

Perhaps you've tried them already??

Perhaps you've tried them already??

Last edited by Bensdexta on Wed Oct 03, 2012 5:51 pm, edited 1 time in total.

Bensdexta - 1961 working for a living!

Re: New Performance Major Rev Counter

Many thanks. I have a feeling that they were the first ones I tried, but I need to check back in my rebuild notes. They may be worth another go, as their experience and availability of parts should have developed over the last 6 years.

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: New Performance Major Rev Counter

Hi Tim

The major difference came when they changed over to Minimec injector pump, this changed the rotation direction as the later unit is driven from the back of the pump rather than the little 90° drive up front.

You may be correct about Ford using different vendors at the same time, my Super Major and the County Super 4 were built only a few months apart and had different units, and again one of them may have been replaced. The County had an AC unit in it.

Pat

The major difference came when they changed over to Minimec injector pump, this changed the rotation direction as the later unit is driven from the back of the pump rather than the little 90° drive up front.

You may be correct about Ford using different vendors at the same time, my Super Major and the County Super 4 were built only a few months apart and had different units, and again one of them may have been replaced. The County had an AC unit in it.

Pat

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: New Performance Major Rev Counter

My 1960 Power Major had an AC drive and AC meter which both were beyond repair. I replaced both also with repro's and the unit has since failed. I have not had time to pick it apart to see why it failed, but may do so at some point. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

Matt 1944 N

- True Blue

- Posts: 105

- Joined: Tue Apr 29, 2008 5:44 pm

- Location: Somerset, England, UK

Re: New Performance Major Rev Counter

I always thought that there were two rev counters for the two different ratio back axles fitted to NP majors, a New Performance revcounter shouldnt have a different bar for raised pto as the new performance raised pto is a 1:1 ratio because they have proper 540

1945 Ransomes MG2, 1950 P6 E27N, 1963 NP Super Major

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: New Performance Major Rev Counter

As I said, I have not investigated, but I have a feeling the problem with the repros is lack of enough lubrication. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

Kiwi Kev

- Site Governance Team & Expert Team

- Posts: 802

- Joined: Thu Apr 17, 2008 7:44 am

- Location: Norfolk Island. South Pacific.

Re: New Performance Major Rev Counter

DaveDandy Dave wrote:As I said, I have not investigated, but I have a feeling the problem with the repros is lack of enough lubrication. Dandy Dave!

I spend abit of time on the net reading forums, and looking at tractors for sale, and it's surprising how many rev counters are not working.

I would like to get a rev counter(repro) for my Major(not that she needs one at the moment, seen that she's died) and one for the 5000

I've been watching this thread and wondering why they fail. Had thought that it would probably be because of lubrication, or lack of.

Would love to hear what you find if you ever get the time to investigate.

Kiwi Kev

"Classic Contracting"

66 Ford 5000 6X (semi retirement)

International 784 4WD

& looking at another tractor!

66 Ford 5000 6X (semi retirement)

International 784 4WD

& looking at another tractor!

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: New Performance Major Rev Counter

Looks like I have now been elected for a mission.  Onward and upward mate. I'll report back back when I get some info and photos. Dandy Dave!

Onward and upward mate. I'll report back back when I get some info and photos. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

marveltone

- Not Quite Blue Yet

- Posts: 35

- Joined: Mon Aug 27, 2012 4:40 am

- Location: Extreme Northern Minnesota

Re: New Performance Major Rev Counter

Dave,

Let us know what you find out. My Major is also in need of a rev counter. I'd hate to shell out good money on a unit that self destructs in short order.

Joe

Let us know what you find out. My Major is also in need of a rev counter. I'd hate to shell out good money on a unit that self destructs in short order.

Joe

1957 Fordson Major Diesel.

Re: New Performance Major Rev Counter

Well, what a tangled web we weave? I was very interested to see that a raised PTO does not need a different rpm "bar", but I have a photograph of an AC one with just that. The other point to consider is the information that anticlockwise rev counters came in with Minimec FIPs. The change to different PTO shaft and ratios came with NP Super Majors, as Fordson found that customers could not drive high HP implements (Such as rotary side delivery dungspreaders). So there was a need for a different rev counter for Super Majors with Minimec FIP, another one for NP Super Majors with different PTO speeds/RPM and then different ones to reflect the different land speeds for those with the higher ratio differentials. Or didn't Ford bother for those with the higher ratio diff? I haven't got my parts list with me at the moment, it would be interesting to see if there were different part nos for up to 4 different rev counters with at least 2 different manufacturers. Many thanks for your interest.

Tim E (just arrived in New York!)

Tim E (just arrived in New York!)

Re: New Performance Major Rev Counter

Many, many years ago my brother-in-law worked as a time and motion engineer at Smiths Industries, Cricklewood, London. As far as speedometers were concerned - those returned under warranty or for repair - he said that a very high proportion of them were because of over lubrication of the speedo cable with grease or oil. Because of the spiral wire windings of the inner cable, which acted as a virtual 'auger', excessive lubricant found itself inside the speedo head itself and gummed up the works. Smiths maintained that the cable should not be over lubricated and that the last foot before it entered the speedo head should be lightly lubed and then WIPED OFF.

Another problem was the ingress of moisture [water/rain], which would apply to out in the weather tractors [even though their speedos were equipped with a rubber sealing ring]. This had the tendency to also cause the small bearing surfaces, with only microns of freeplay, to induce drag and eventually seize.

For over zealous lubrication, provided the pointer could still be gently turned by hand, de-greasing the whole unit by immersion in petrol, then metho, usually restored proper movement and the bearing surfaces were then oiled again with something the equivalent of sowing machine oil.

As far as the contaminated bearing surfaces were concerned, if not too bad then machine oil sometimes helped. I have also, in the past, found that a light coating of silicon cement between the glass and body keeps moisture out.

I should mention, though, that in all instances the heads were then re-calibrated. As well, anyone contemplating the stripping down of the head for investigation must not, under any circumstances, remove the pointer/needle as all calibration would then be lost.

Pavel

Another problem was the ingress of moisture [water/rain], which would apply to out in the weather tractors [even though their speedos were equipped with a rubber sealing ring]. This had the tendency to also cause the small bearing surfaces, with only microns of freeplay, to induce drag and eventually seize.

For over zealous lubrication, provided the pointer could still be gently turned by hand, de-greasing the whole unit by immersion in petrol, then metho, usually restored proper movement and the bearing surfaces were then oiled again with something the equivalent of sowing machine oil.

As far as the contaminated bearing surfaces were concerned, if not too bad then machine oil sometimes helped. I have also, in the past, found that a light coating of silicon cement between the glass and body keeps moisture out.

I should mention, though, that in all instances the heads were then re-calibrated. As well, anyone contemplating the stripping down of the head for investigation must not, under any circumstances, remove the pointer/needle as all calibration would then be lost.

Pavel

Re: New Performance Major Rev Counter

Don't know if this will help or hinder, but this is the face of a scrap tacho that came with the PM last year.

I don't even know if it belonged to a power major originally.

I don't even know if it belonged to a power major originally.

'Lily' 1959 Fordson Power Major

Re: New Performance Major Rev Counter

Dear Halloween

So you have a clockwise Smiths which is correct for a Power Major, with 2 speed "bars" for PTOs, one for Standard PTO and another for Raised PTO. Matt's point about NP Supers with a Raised PTO at 1:1, then makes one wonder why earlier Majors with Raised PTOs were not 1:1, or were they? Getting very confused now.

Tim

So you have a clockwise Smiths which is correct for a Power Major, with 2 speed "bars" for PTOs, one for Standard PTO and another for Raised PTO. Matt's point about NP Supers with a Raised PTO at 1:1, then makes one wonder why earlier Majors with Raised PTOs were not 1:1, or were they? Getting very confused now.

Tim

Re: New Performance Major Rev Counter

Hi

all the majors up until the blue grey super ( new performance) had the same pto 540 was at a fast idle (around 1200 rpm), so used the same raised unit. It bought the motor revs up and got the 540 at more usable higher rpms .

The new performance was geared for 540 pto at higher engine revs like 1500, so it only needed the 1:1 gear ratio. All this unit did on blue greys was to raise the height of the shaft to standard height. And allowed the use of hydraulics without the pto turning as with the older ones. This is why you have to be carefull what the unit came from to match the higher pto speed engine revs, This is why they are like rocking horse poo to find for the NPSM, not many guys had them fitted from new as they didn't need them for there application.

Regards Robert

all the majors up until the blue grey super ( new performance) had the same pto 540 was at a fast idle (around 1200 rpm), so used the same raised unit. It bought the motor revs up and got the 540 at more usable higher rpms .

The new performance was geared for 540 pto at higher engine revs like 1500, so it only needed the 1:1 gear ratio. All this unit did on blue greys was to raise the height of the shaft to standard height. And allowed the use of hydraulics without the pto turning as with the older ones. This is why you have to be carefull what the unit came from to match the higher pto speed engine revs, This is why they are like rocking horse poo to find for the NPSM, not many guys had them fitted from new as they didn't need them for there application.

Regards Robert

A Fordson is for life not just for Christmas !.