Hydraulic manifold cracked

Hydraulic manifold cracked

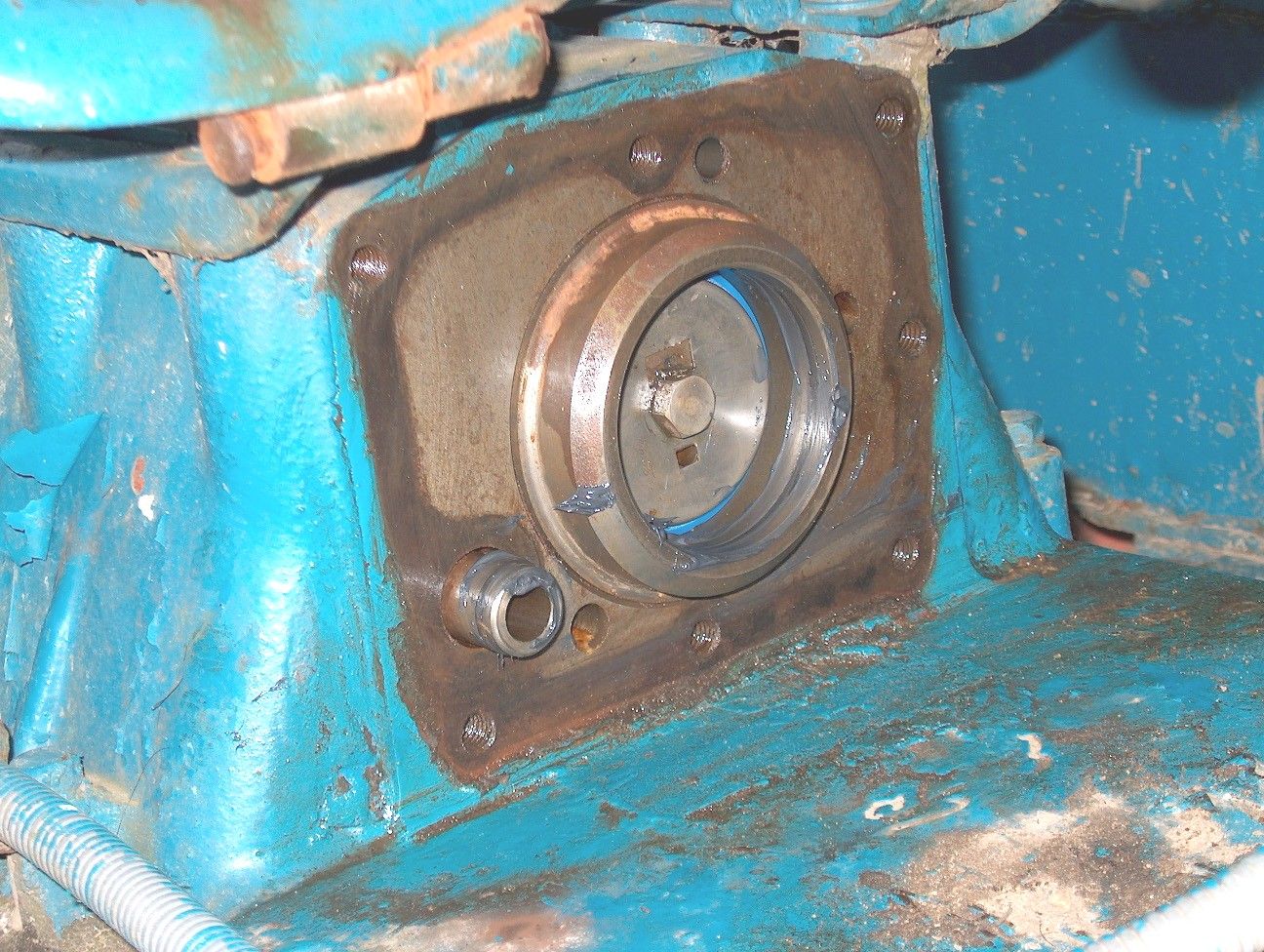

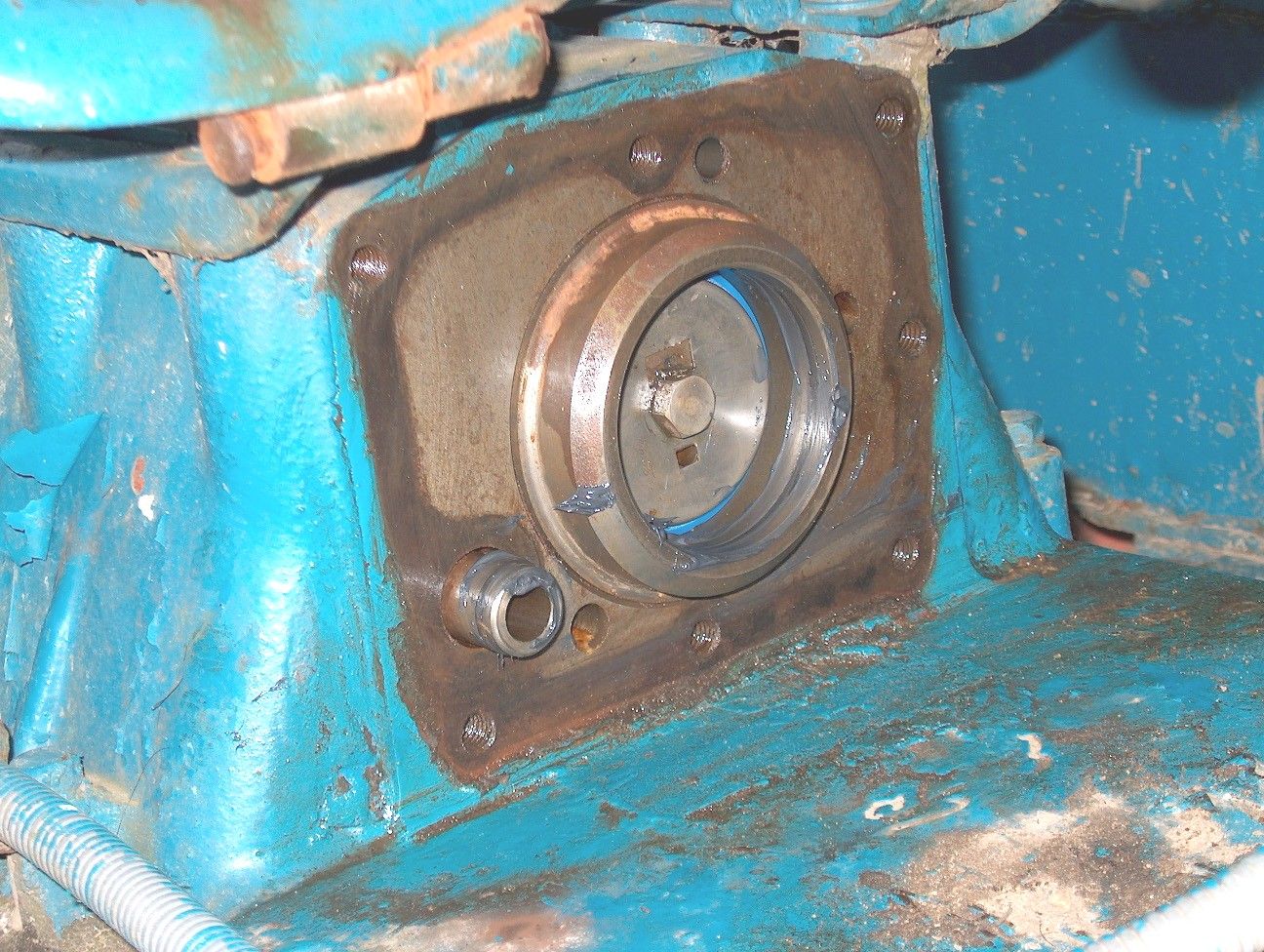

I'm on the final stage of rebuilding my '54 Major, after a complete rebuild i fired up the engine for the first time yesterday. Engine runs great, by i tried using the hydraulic lift, and when it reached it's highest point i heard a crack. Oils started pooring out of the hydraulic manifold. It seemed that the lid cracked at the topleft bolt. Could this be a faulted pressure valve of faulted O-ring somewhere?

Secondly, can this be repaired and how should i try and do that? It's casted iron, so welding could be tricky. I know the best option is going for another manifold, but they are hard to find and very expensive.

Secondly, can this be repaired and how should i try and do that? It's casted iron, so welding could be tricky. I know the best option is going for another manifold, but they are hard to find and very expensive.

Re: Hydraulic manifold cracked

Not quite sure what you mean by "hydraulic manifold" Tracy.

The pressure comes from a pipe in the centre of the rear axle then via a second pipe to the valve chest at the front of the lift. If your Pressure Relief valve jammed, I would have expected the pump to fail. I had it happen once and it blew the 5000 psi pressure guage and split the pump in half but did not damage any casting or "O" ring.

Piston and pressure pipe to the valve chest.

Valve chest.

The pressure comes from a pipe in the centre of the rear axle then via a second pipe to the valve chest at the front of the lift. If your Pressure Relief valve jammed, I would have expected the pump to fail. I had it happen once and it blew the 5000 psi pressure guage and split the pump in half but did not damage any casting or "O" ring.

Piston and pressure pipe to the valve chest.

Valve chest.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: Hydraulic manifold cracked

Brian, i used your picture to mark where the crack occured, maybe that will explain a bit more. It's not a big crack, but it's gone all the way from the top to the left side, all around the bolt, and it leaks hydraulic oil there.

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Re: Hydraulic manifold cracked

You could try and find a machine shop. It's not a hard job to make a new one.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

-

easy.start

- True Blue

- Posts: 55

- Joined: Sun Jun 14, 2015 10:57 pm

- Location: Somerset, UK

Re: Hydraulic manifold cracked

High Nickel cast iron welding rods are relatively cheap (especially for the amount you would need to weld) and are easy to use if using an inverter welder (or arc welder really). Search on the online auction site.

Take the chest off, lay it flat, grind a channel to fill with weld and bolt back on! Only one thing, why did it crack there in the first place

I'd be doing some basic visual checks first before welding it back together

Take the chest off, lay it flat, grind a channel to fill with weld and bolt back on! Only one thing, why did it crack there in the first place

I'd be doing some basic visual checks first before welding it back together

Easy Start (not required for the Fordson)

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: Hydraulic manifold cracked

And if you are not comfortable welding it and don't have a tame welder handy, a good clean and degrease and SifBronze braze will also work if you have a decent sized propane torch, Thermalite or Durox building blocks (dry!) make a good base and back for a temporary hearth to keep the heat in.

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

-

easy.start

- True Blue

- Posts: 55

- Joined: Sun Jun 14, 2015 10:57 pm

- Location: Somerset, UK

Re: Hydraulic manifold cracked

True oehrickoehrick wrote:And if you are not comfortable welding it and don't have a tame welder handy, a good clean and degrease and SifBronze braze will also work if you have a decent sized propane torch, Thermalite or Durox building blocks (dry!) make a good base and back for a temporary hearth to keep the heat in.

Easy Start (not required for the Fordson)

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: Hydraulic manifold cracked

You are quite right easystart but on something of this thickness full penetration welding and melting the corner off if too hot or leaving a leaking crack if not hot enough still remains a bit of a challenge. Unless I missed it I don't think Tracy mentioned a location and some of our number can be pretty remote !

How about weld for strength and if a leak remains degrease again and braze over as a compromise ??

Still begs the question if this is a recent failure due to some sort of pressure 'event' or an age old fatigue fracture which has finally let go - insufficient info so far

How about weld for strength and if a leak remains degrease again and braze over as a compromise ??

Still begs the question if this is a recent failure due to some sort of pressure 'event' or an age old fatigue fracture which has finally let go - insufficient info so far

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: Hydraulic manifold cracked

It will be pretty strange if that corner alone cracked off due to pressure as there are so many other bolts holding the valve chest on that have not failed. Could possibly be some object between the gasket/front housing that stopped the chest seating properyly when it was tightened down.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Re: Hydraulic manifold cracked

I was a bit dissy I think. Thought the crack wat at the place of the word but now I see it's the corner. A bit hard to machine that part.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

-

easy.start

- True Blue

- Posts: 55

- Joined: Sun Jun 14, 2015 10:57 pm

- Location: Somerset, UK

Re: Hydraulic manifold cracked

I agree oehrick and Brian. Having over the past year stripped and rebuilt my first blue Fordson, including the hydraulics, it seemed odd to me too that only this top left cracked off. As you mention Brian, the chest is indeed well bolted on. Makes me wonder whether the chest was securely bolted on or, as suggested, wasn't seated correctly for some other reason.

I would weld it as the chest is bolted on in so many other locations and this corner bolt serves to sandwich the gasket Or braze as I've had some success brazing the exhaust manifold on the P6 and stick welding a block of a MH, although my daughter was pretty miffed about her sandpit being emptied for the purpose

Or braze as I've had some success brazing the exhaust manifold on the P6 and stick welding a block of a MH, although my daughter was pretty miffed about her sandpit being emptied for the purpose

I would weld it as the chest is bolted on in so many other locations and this corner bolt serves to sandwich the gasket

Easy Start (not required for the Fordson)

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Re: Hydraulic manifold cracked

I would try to braze it. I think it will give less change to crack somewere else due to tension. Warm it up before on a heating plate. Let it coole down in sand to slowdown the cooling

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I