Page 1 of 1

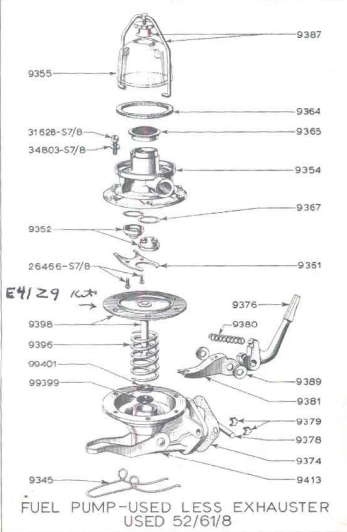

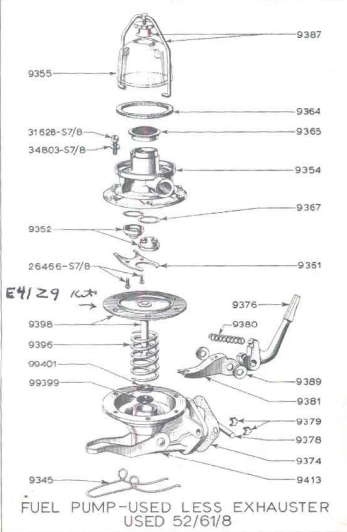

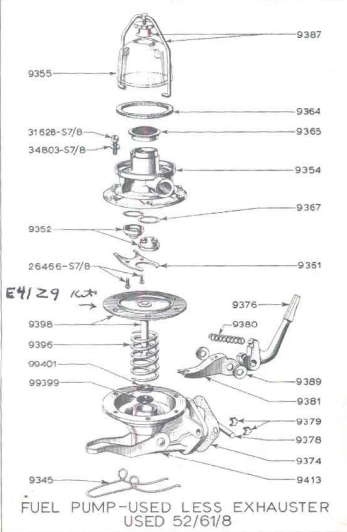

Fuel lift pump and glass bowl

Posted: Mon May 10, 2010 4:35 pm

by Ian

So we were using our tractor the other day to pull out some fence posts, and it totally conked out. Started it up, it did the same. Realised air was getting into the the fuel system from the fuel lift pump, or around the glass bowl more specifically, and diesel was leaking out. The seal seems to have gone. When I took it apart to clean it I realised the little gauze thing has also gone. Agriline do a seal, only £2, but where can i get a replacement gauze ? Didn't especially want to buy the whole thing.

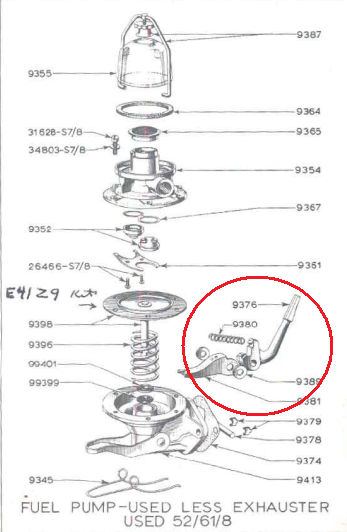

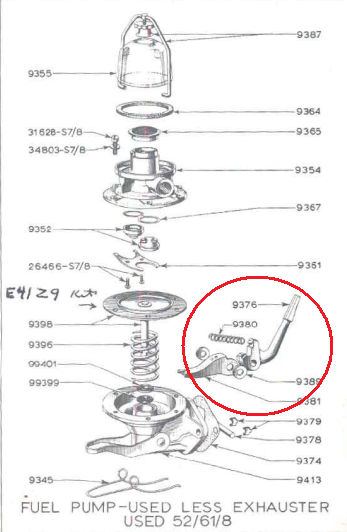

The parts are 9364 and 9365

Posted: Mon May 10, 2010 5:50 pm

by henk

Ian,

I know there are repair set for sale. Agriline must have them. Old20 sells them to.

Fuel lift pump and glass bowl

Posted: Mon May 10, 2010 6:35 pm

by devondom

Hi

It sounds like the pump could do with an overhaul.

A Major Lift Pump Repair Kit will cost about £12. It is probably

worth getting it as a bad pump will cause the tractor to run

erratically and could damage the engine.

Posted: Mon May 10, 2010 6:46 pm

by Tmac

When I acquired my first FMD (54) in the early 90s I run into the same problem. This was before the Inet and parts were scarce for this machine. So I rebuilt the screen and resurfaced the glass bowl.

To repair the screen I removed the inner and outer rim very carefully. First I put it on a hot plate and heated it very hot then dipped it in water, this annealed the brass rims. I just then happened to have some matching screen. I cut the screen to fit the rims closed them down. While the original screen wasn't soldered in, I did put a touch of solder on both rims in spots to make sure it stayed together. That screen is still in place today.

This isn't the easiest or cheapest way to fix, but if all else fails it is an option.

Posted: Mon May 10, 2010 7:08 pm

by Grani

Every time i look at a Major fuelpump i wonder if the designer of it was holding the drawing upside down. All the dirt ends up in the pump mechanism instead of in the easy cleaned bowl.

The Trader pump designer held it right.

Posted: Mon May 10, 2010 7:21 pm

by Tmac

Grani

The Ag model is the only FMD?SMD that uses the upside down pump. The Industrial models use a bowl that is separate from the pump.

When I got my first Major and had the pump off for the first time, I had no manuals or Inet to go to and FMDs were SCARCE in my area, I reinstalled the boost pump upside down, I just forgot which way it was. Of course every other pump ever made, at least in the USA, had the bowl correctly installed

) with bowl on the bottom. I quickly found that way wrong as it had NO pumping action.

Posted: Wed May 12, 2010 1:28 pm

by Ian

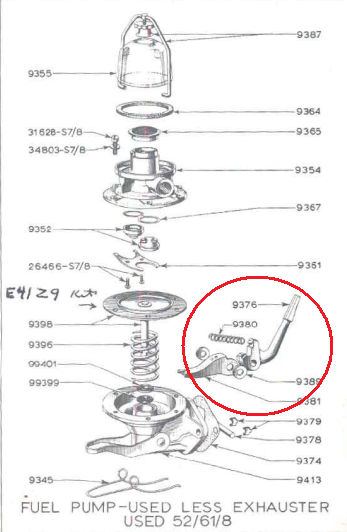

Okay, I bought a new fuel lift pump with glass bowl. Now my only question is, what is the part circled for ? Does this attach to something inside ?

Posted: Wed May 12, 2010 4:29 pm

by Gman

Ian wrote:Okay, I bought a new fuel lift pump with glass bowl. Now my only question is, what is the part circled for ? Does this attach to something inside ?

Hello Ian, this part of the pump goes into the block. Once you remove the old one you can see inside where it fits to the cam. You will need to turn the engine in order for it to be easy to install new pump.

Posted: Wed May 12, 2010 4:32 pm

by Ian

turn the engine ? What does this part do ?

Is oil gonna leak out when I remove this ?

Posted: Wed May 12, 2010 4:48 pm

by Tmac

This is the pump actuator arm it is moved back and forth by a special lobe on the camshaft. This arm shouldn't be either removed from the pump or be off a new one. Nothing leaks from the pump when the pump is taken off the engine. That is unless you have fuel in the tank and forget to shut the valve on the tank!!

Posted: Wed May 12, 2010 4:56 pm

by Ian

I see, does this somehow pump the fuel through the system ?

Posted: Thu May 13, 2010 1:23 pm

by Dandy Dave

There is an eccentric in the cam shaft that the pump arm rubs against. The arm is spring loaded so that it will be in contact with the cam to pump the fuel. Inside of the pump there is a diaphram and that arm actuates. If you hold the pump and push the arm toward the pump you will feel the resistance. It will push a little hard. Also you will hear the valves burping. Be sure that when you install the new pump that the arm is tucked up in so that it is rubbing against the cam. Just put in the two bolts and hook up the lines and you are good to go. If you are just curious as to how it works, just take the old one apart and it will be fairly straight forward for anyone with a Mechanical mind.

In fact, look here.This is the same basic principal that our Fordson pumps work on. Dandy Dave!

http://www.secondchancegarage.com/public/535.cfm

Posted: Thu May 13, 2010 3:47 pm

by Ian

Many thanks Dandy Dave, that filled the gap in my knowledge perfectly ! I thought the fuel injection pumped sucked the fuel through the system, I didn't realise there was a seperate pump for this.

Right.. I installed the new pump. But it doesn't work at all. At least the level on the outside does nothing at all. When I open up the bleed valve and started it up, the glass bowl fills up, and soon it starts chucking diesel out the side of the pump. So clearly I installed it correctly, just the outside primer does absolutely nothing. Have i been sold a dud ? The old one still works okay, just clearly all the seals have gone on it. I also managed to spray diesel in my face lol.

Posted: Thu May 13, 2010 8:24 pm

by john.n

try the pump after turning the crank one revolution by hand. the cam could just be at the top of its stroke.

Posted: Thu May 13, 2010 8:33 pm

by Ian

How do i turn the crank? I tried turning it over a few times with the starter

Posted: Thu May 13, 2010 9:15 pm

by henk

Ian,

Lift the valves with the lever in front of the valve cover.

Use a wrench on the nut in front of the engine.

Posted: Thu May 13, 2010 10:50 pm

by Ian

i just turned the engine over with the starter, and the pump worked fine. Clearly it was just in the wrong position. But when i loosened the bleeder bolt on the pump, the head snapped off ! Disaster. I've no clue how to get the rest of it out. If it was anywhere else i'd just drill it out, but i cant risk getting metal in there.

Posted: Fri May 14, 2010 12:49 pm

by Dandy Dave

You should bleed the fuel filter first, and then the injection pump. The only way I know of to remove a broken plug is to drill a hole. Sometimes you can use an "easy out" I have sometimes used a magnet to remove metal filings from a hole. kind of touchy work around an injection pump though. Dandy Dave!

Posted: Fri May 14, 2010 1:53 pm

by Gman

Ian wrote:i just turned the engine over with the starter, and the pump worked fine. Clearly it was just in the wrong position. But when i loosened the bleeder bolt on the pump, the head snapped off ! Disaster. I've no clue how to get the rest of it out. If it was anywhere else i'd just drill it out, but i cant risk getting metal in there.

Hi Ian, when I worked in a machine shop when I came out of high school we had a lot of screws we had to remove with the head broken off. We drilled a small hole into the screw, not all the way through to avoid metal going in, then would tap a piece of metal that was like the end of a flat head screw driver into hole and back the screw out, most easy outs were to large because the screws were small similar to the bleed screw on the pump. Good luck.

Posted: Fri May 14, 2010 3:02 pm

by Ian

I managed to get it out with a hammer and a chain saw file. Just twisted it around inside and it popped out. No drilling required.

I measured the bolt with a ruler, i think it's 3/8 BSW, gonna try and get a new one today.

Posted: Fri May 14, 2010 3:10 pm

by Gman

Ian wrote:I managed to get it out with a hammer and a chain saw file. Just twisted it around inside and it popped out. No drilling required.

I measured the bolt with a ruler, i think it's 3/8 BSW, gonna try and get a new one today.

Good job Ian, check the parts manual on this site and it may give you correct size of bleed screw.