Water leak! Help please!

Water leak! Help please!

Ive just put the head back on my major, torqued it down etc (my mate did this for me). So earlier i filled the rad up with water just to check for leaks, and after 10 mins or so, water started seeping out the where the head gasket is, and through the sump. So i emptied it out again, and checked the head bolts one by one, and low and behold, one was loose (could move it with my finger). So its now tightened up and after 2 hours is now holding water gladly, however there does seem to be a slight water leak coming from around the throttle rod, exhaust side where it goes through the block. What can i do about this? Also what are your thoughts on the first leak?

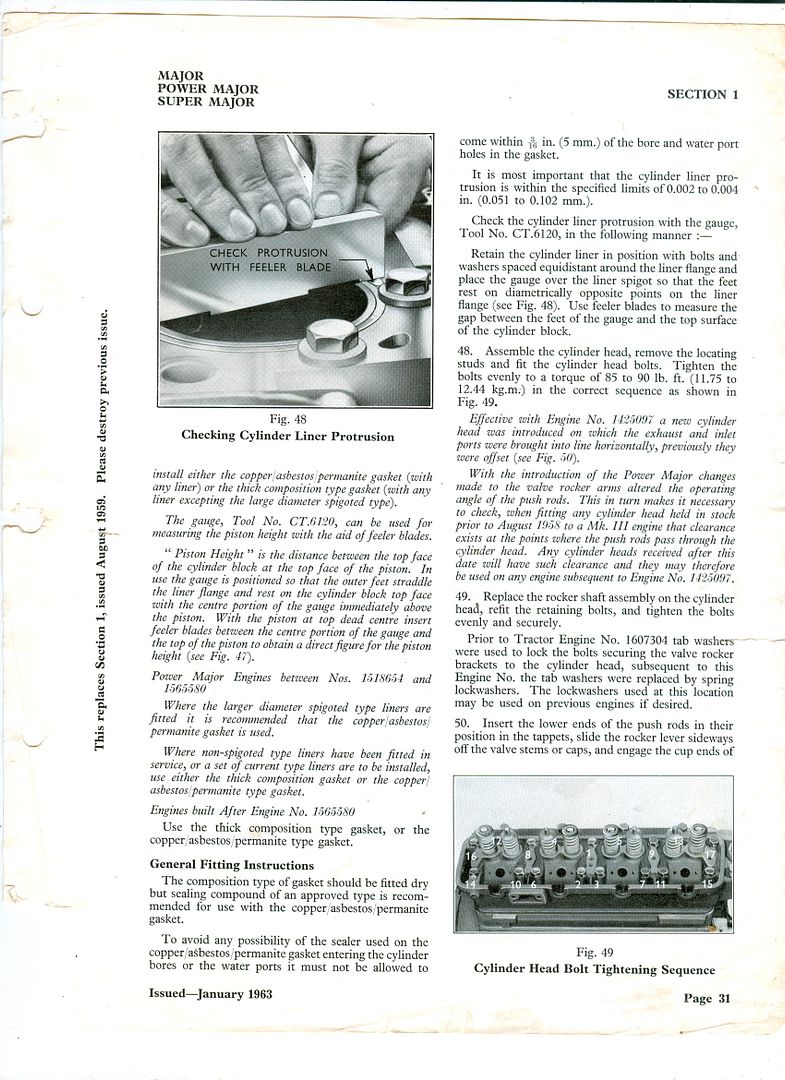

well, its still leaking unfortunately, but less than before. I think the liner protrusion is too much for the head gasket to seal, however they were properly measured, so its off with the head too see what is wrong i think. Just so ive got this right, the outside ring of the liner should protrude 0.002 - 0.004, am i right?

I seem to remember those are the figures Brian quoted.

Just a few thoughts here.

Are you measuring them from the right place and are you sure there are no hair line cracks in the head / block. or that the head/block is not warped that could be causing it to weep from the gasket.

I hope something here helps you.

I know you have put a lot of work into getting this right for your first go at a motor re build .

.

I wish I was a bit closer than Canada As I would come and help you with it.Actually seeing the problem can give better problem Diagnoses than a description and messages.

good luck

Regards Robert

Just a few thoughts here.

Are you measuring them from the right place and are you sure there are no hair line cracks in the head / block. or that the head/block is not warped that could be causing it to weep from the gasket.

I hope something here helps you.

I know you have put a lot of work into getting this right for your first go at a motor re build

I wish I was a bit closer than Canada As I would come and help you with it.Actually seeing the problem can give better problem Diagnoses than a description and messages.

good luck

Regards Robert

A Fordson is for life not just for Christmas !.

well i hope i was measuring from the correct place, there are two surfaces at the top of the liner, i was measuring the lower part, should it have been the top part? The head has been skimmed and tested and i cant see any cracks in the block. Thing is it wasnt leaking out of here before, so it must be something ive done wrong

Thankyou for your reply mate

Thankyou for your reply mate

The lower surface is correct.

The gasket you have used to be called a "Klinger" gasket and was used on all the Majors at the end of production and into preservation. It is the one I have on my petrol/paraffin 1952 Major.

I think Henk had a similar problem in an earlier post but it is something I have not come across.

Did you use guide studs to hold it all in place when you dropped the head on?

The gasket you have used to be called a "Klinger" gasket and was used on all the Majors at the end of production and into preservation. It is the one I have on my petrol/paraffin 1952 Major.

I think Henk had a similar problem in an earlier post but it is something I have not come across.

Did you use guide studs to hold it all in place when you dropped the head on?

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

no there were no studs in the head or the block, but all the head bolt holes lined up ok. What made me think it was the liners being too high was my old super major next door, there is a hell of alot of difference in this one and that one in that mine stick out more, so i reckon this is the problem, wish i had seen this before i put the head on!

The studs are just to hold things in line whilst you get the head on. We made them and they saved hours. You thread them into a couple of holes, lower the head down, thentake them out once you have a couple of bolts back in.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

right, head is back off now. Its obvious that water has got everywhere and the gasket feels soaking wet. Now ive looked at the liners again, im not so sure it is that. The head was torqued up to 90 ft/lbs, which is roughly 120nm i think. What does stick in my mind is when i tightened it down first, and it leaked alot, then tightened it down properly and it took over night to leak.

Hi Nick, I hope you find your problem. I believe I need to put a head gasket on my Power Major and hope to see if I can do it this winter. Do you have any pictures? Also I seem to remember reading there is a small water seal between head and block that must be replaced. Do you have to remove exhaust and intake manifolds to take head off? Thanks and good luck.

Gman: 1959 Power Major

i havent taken the inlet and exhaust off my head. i havent taken any pictures of what ive done recently, but there are some pictures on a previous thread of when the liners were out etc. Ive just come in from the thread after blacking the surface of the head with a parrafin and oil flame and ran a straight edge along the head, straight as a die. Just one thing, the new gasket really stuck to the head so ive found when i took it off, is this normal? Could all this leaking just be because the head bolts werent done in the proper order?

On those heads the order of the bolt tightening is not an issue. It is better to tighten them in order but it is not the end of the world if you did not do it in the correct order.

The seal Gman mentions is an oil seal for the rocker shaft feed.

The problem you have means the head was not down on the gasket. It could be that the head bolts have bottomed out and the head was not down tight on the gasket. Something prevented the head coming down on the gasket.

The seal Gman mentions is an oil seal for the rocker shaft feed.

The problem you have means the head was not down on the gasket. It could be that the head bolts have bottomed out and the head was not down tight on the gasket. Something prevented the head coming down on the gasket.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

just tried putting bolts in all holes and did them up til they stopped, measured them and the head and it seems that is not the problem!

Im starting to think that after i found that loose head bolt and it stopped leaking, it had sealed it up, and the small amount of water i was seeing coming out (looked like it was sweating) was just the gasket drying out?

Im starting to think that after i found that loose head bolt and it stopped leaking, it had sealed it up, and the small amount of water i was seeing coming out (looked like it was sweating) was just the gasket drying out?

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Nick,

I had a lot of problems putting a new head gasket on. It was all because I had never done it before.

I suggest you buy a new one. And a new oil seal that is under the gasket. Be sure the bolts go in easy with your hand. Clean the bolts and holes very well and oil them a bit.

When putting the head on use four guiding rods that you screw in the holes. Because you have not removed the manifold its not easy to lay it straight on. Tighten the bolt in a round of five and giving it higher torque every round. The bolts must turn and not jump. Use the right sequence.

That has done the trick for me.

My topic about this subject:

http://www.fordsontractorpages.nl/phpbb ... et&start=0

Good luck.

I had a lot of problems putting a new head gasket on. It was all because I had never done it before.

I suggest you buy a new one. And a new oil seal that is under the gasket. Be sure the bolts go in easy with your hand. Clean the bolts and holes very well and oil them a bit.

When putting the head on use four guiding rods that you screw in the holes. Because you have not removed the manifold its not easy to lay it straight on. Tighten the bolt in a round of five and giving it higher torque every round. The bolts must turn and not jump. Use the right sequence.

That has done the trick for me.

My topic about this subject:

http://www.fordsontractorpages.nl/phpbb ... et&start=0

Good luck.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Nick,

They are just round bars of steel with the outer dia that fits just in the threaded holes and a length so you can fits them out when the head is on and a round or chamfered top for easy finding the holes. Put them in the outer holes. I would advise to remove the manifold. It's to heavy on one side.

I have no picture.

They are just round bars of steel with the outer dia that fits just in the threaded holes and a length so you can fits them out when the head is on and a round or chamfered top for easy finding the holes. Put them in the outer holes. I would advise to remove the manifold. It's to heavy on one side.

I have no picture.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Hi Nick, when I put the head back on my Super I had coolant leaking out as well, and the head had been installed and torque properly. When I pulled the head back off everything looked good, liner protrusion, gasket was in the correct place, but after looking closer in the suspect area with a striate edge I found a low spot in the block. I used a light coating of ether loctite gasket eliminator or silicone/RTV on the head gasket staying away from the cylinder seal area, I even used the same head gasket over (it hadn’t been run yet) and everything sealed up fine.

Pat

Pat

result! i have now put it back on and its ok! Got another new gasket aswell, however the new one they sent, was MUCH better quality than the one in the re-build kit (Agriline). Just got the front axle to put back on and then i can wheel her out and start her. This hopefully will be sometime in the week or next weekend. How many people does it take to get it back on do you reckon?