Super Sue

Posted: Sun Aug 14, 2011 3:36 pm

A few years ago some of you may remember, I acquired a Super Major from a friend. She was in a poor state having stood in an orchard for many years and then standing in my friends open barn for about five years. The first thing I did to her was to get the engine started and to make sure everything worked. It would give me an idea on whether she would be broken up or renovated.

On removing the lift to free the unload valve I found she had been fitted with a new ram cylinder just before she was stood up so that was a good sign.

Note the lifting ring for the crane.

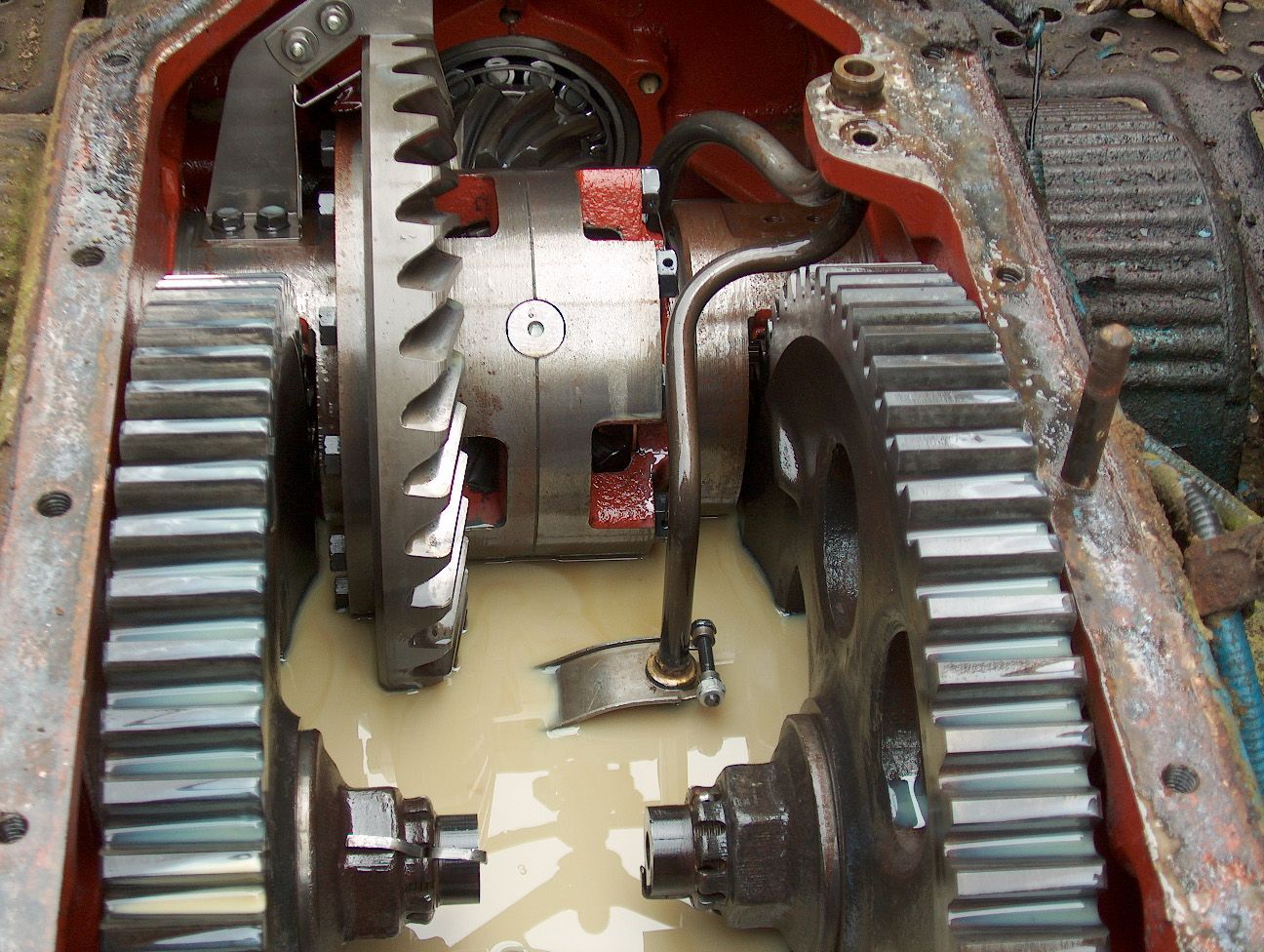

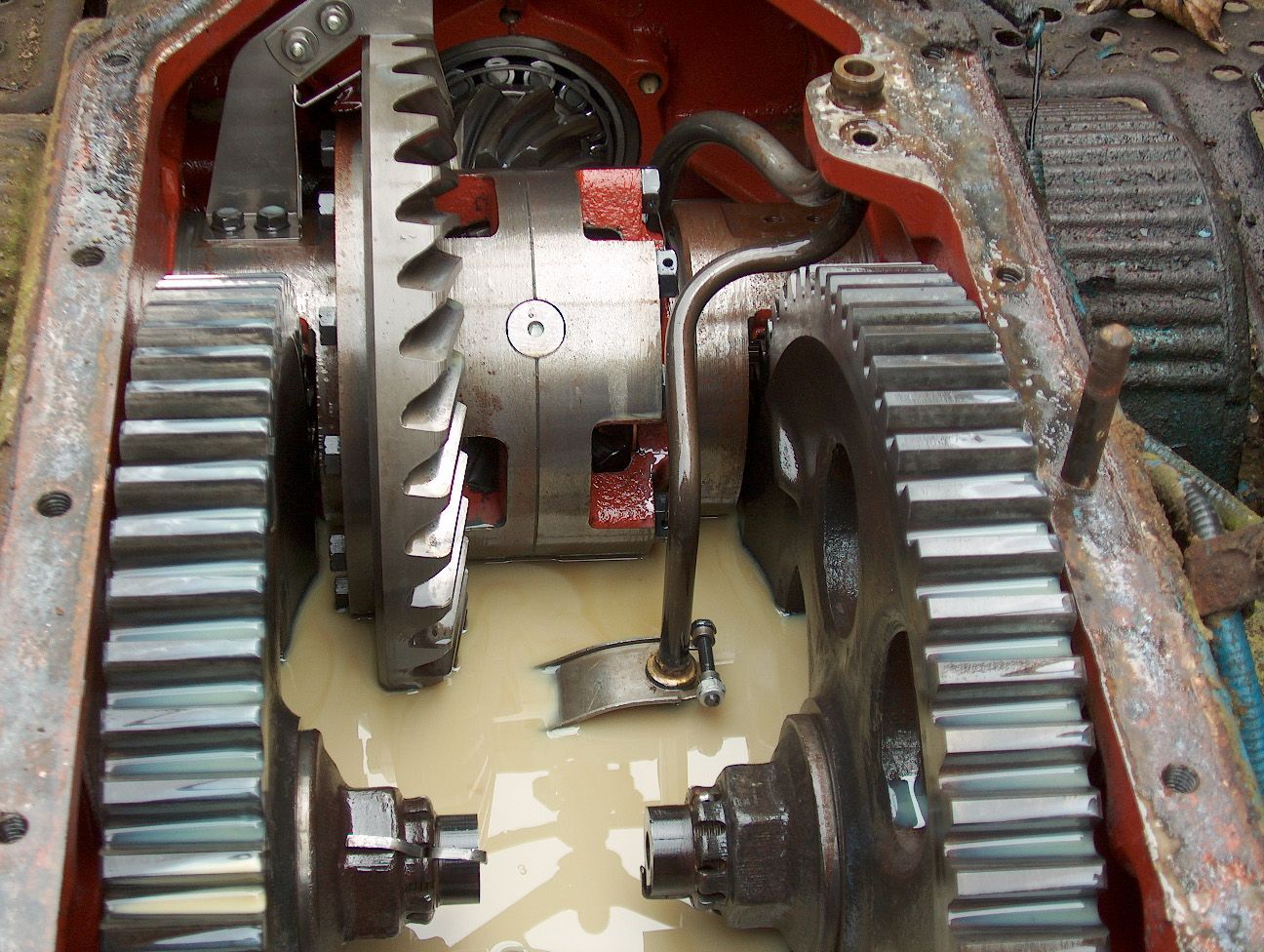

Oil is milky due to water but all else is lovely and clean.

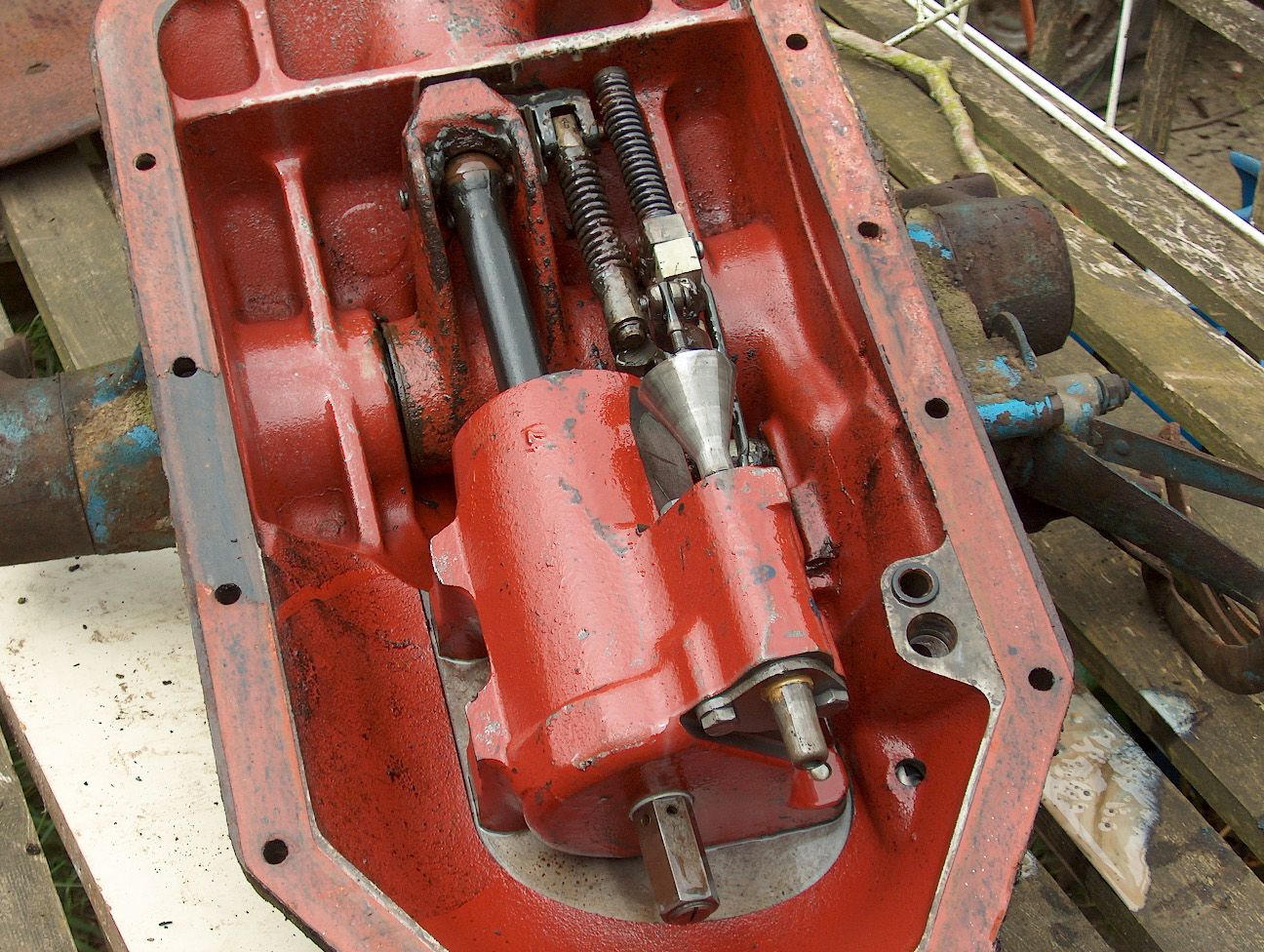

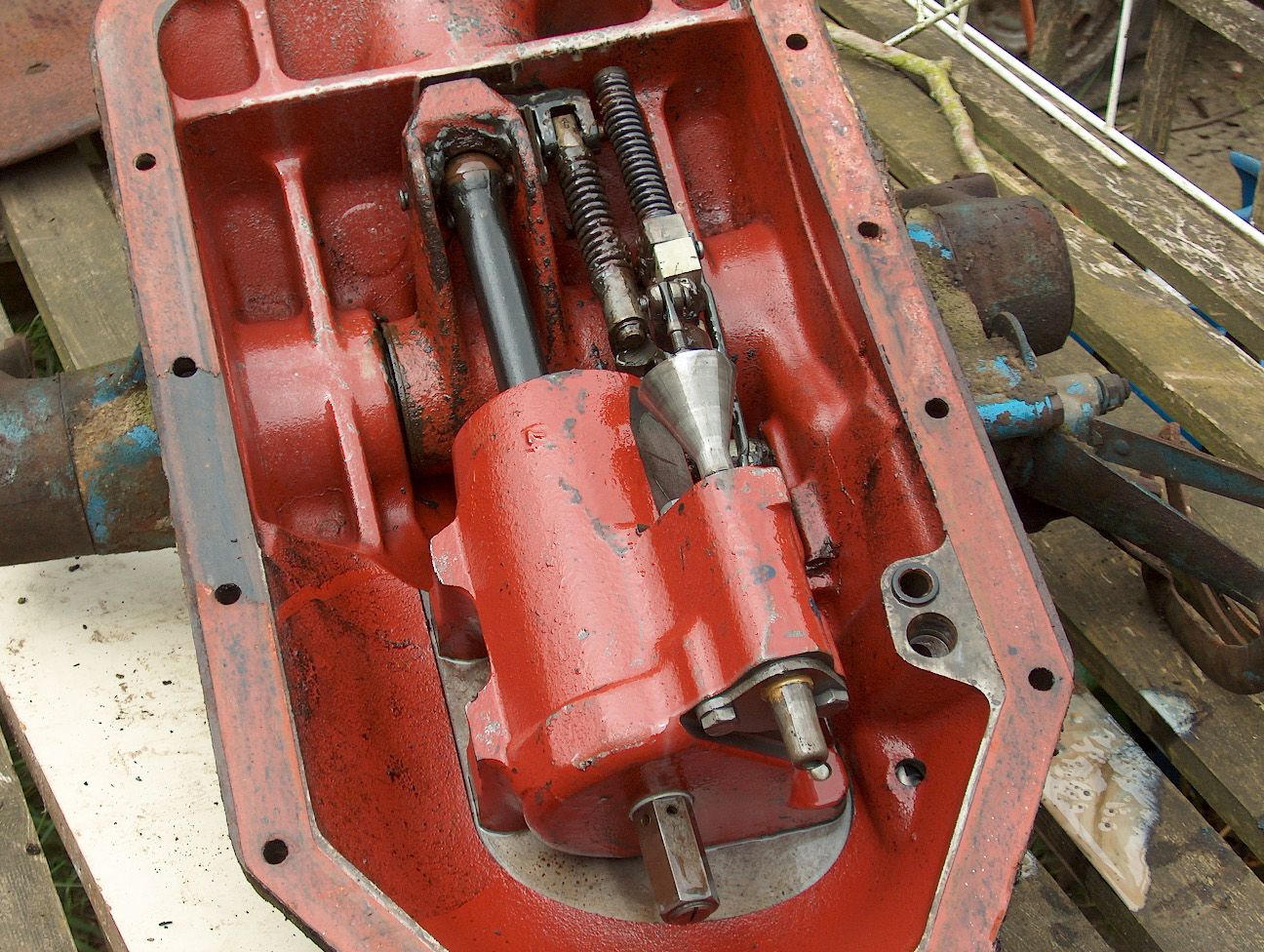

Lift upside down on the bench.

Stuck unload valve. PLEASE NOTE: Do not drive unload valve and plug out from here with a punch! The punch is only used as a pointer. I pulled the plug using an old socket and a bolt threaded into the plug.

The unload valve and unload valve plug. Note the later style piston ring. When fitting these type extreme care has to be taken not to break the cast ring. I hold them in place with thick grease. There is a special tool.

With the lift working and the engine running I put her on various implements over the next year to give her a workout. I found that she had oil leaks from both side axle shafts, a gear lever that turns completely round 360 degrees, an engine that smokes like a train under full load although this did dissipate as she worked, and the reason for the pipe fitted to the timing cover breather, as on the first day vast amounts of oil poured from here all over the front wheel. This again cleared as she worked on the plough and our big cultivator.

All in all, the engine pulled like a train in work, with no gearbox problems other than the usual noise. She had no brakes, these were seized solid but not stuck on, terminal rot had set into the wings and cowl, she had odd wheels but had all the other basic components like dash panel and covers.

According to all the casting codes and serial number, she is totally original so that fact also coloured my decision to renovate.

After making the decision to move a little further into restoration mode, I too parked her up and left her on our field. It was a case of out of sight, out of mind, until this year when we cleared the hay and I saw her looking all forlorn, I grasped the nettle and started on the full restoration.

We towed her home behind Rover, (this time I made sure Ann was in Low Box as a Super is unsafe at speeds of over 60 mph) ( You do not know that story? OK I will tell it one day), by this time our yard is looking very crowded but we found a clear spot and the work has started.

( You do not know that story? OK I will tell it one day), by this time our yard is looking very crowded but we found a clear spot and the work has started.

First job was to get the wheels and wings off then get rid of the Flatford Safety frame. This had been "bodged" on and had been the cause of damage to the footplates due to stretching the wings to fit after raising them up 1" on top of the frame mounting plates. Once this was done the tractor gained at least £100 in value just by looks alone.

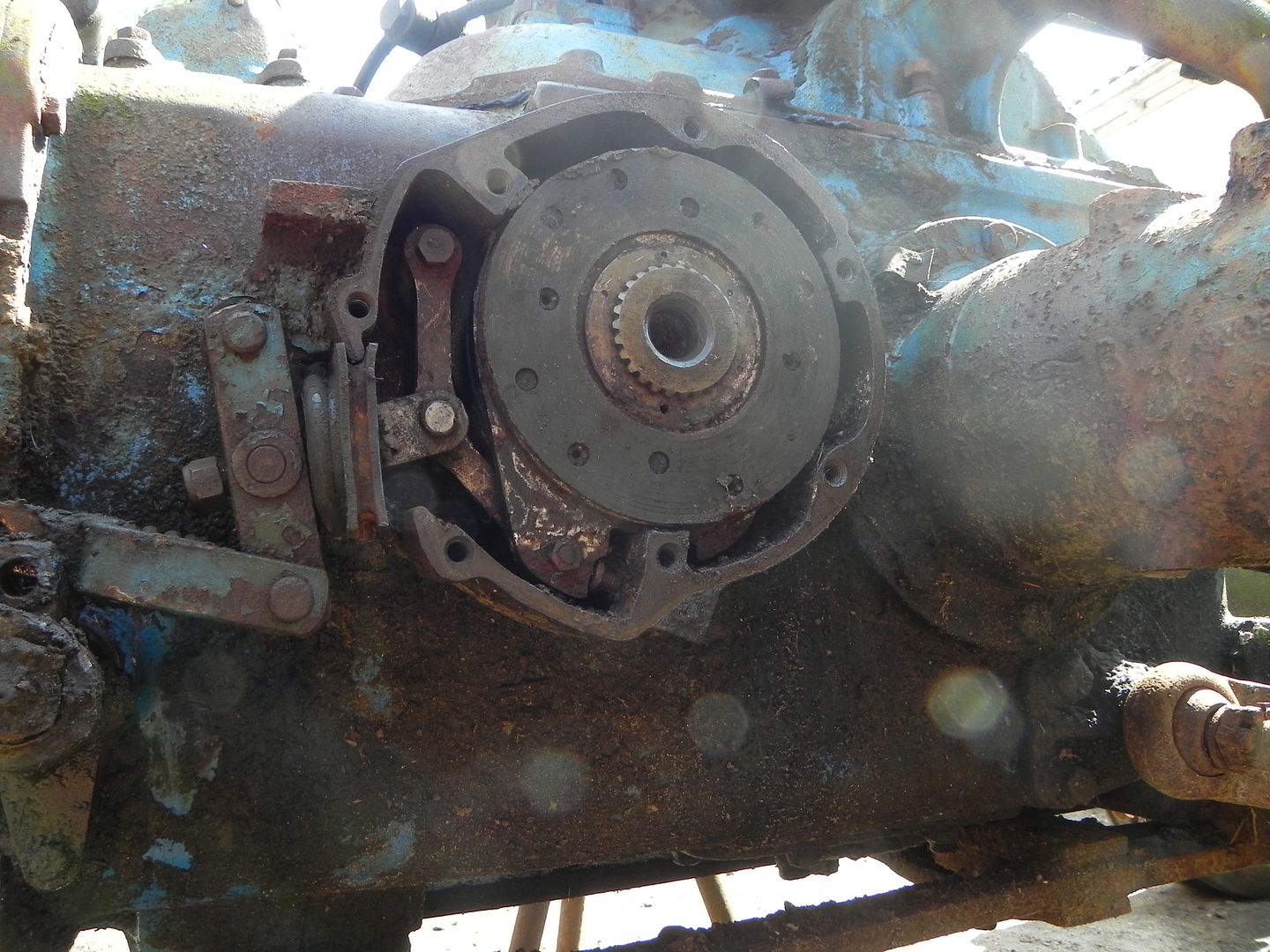

Next job was to remove the footplates and put to one side whilst I check the disc brakes.

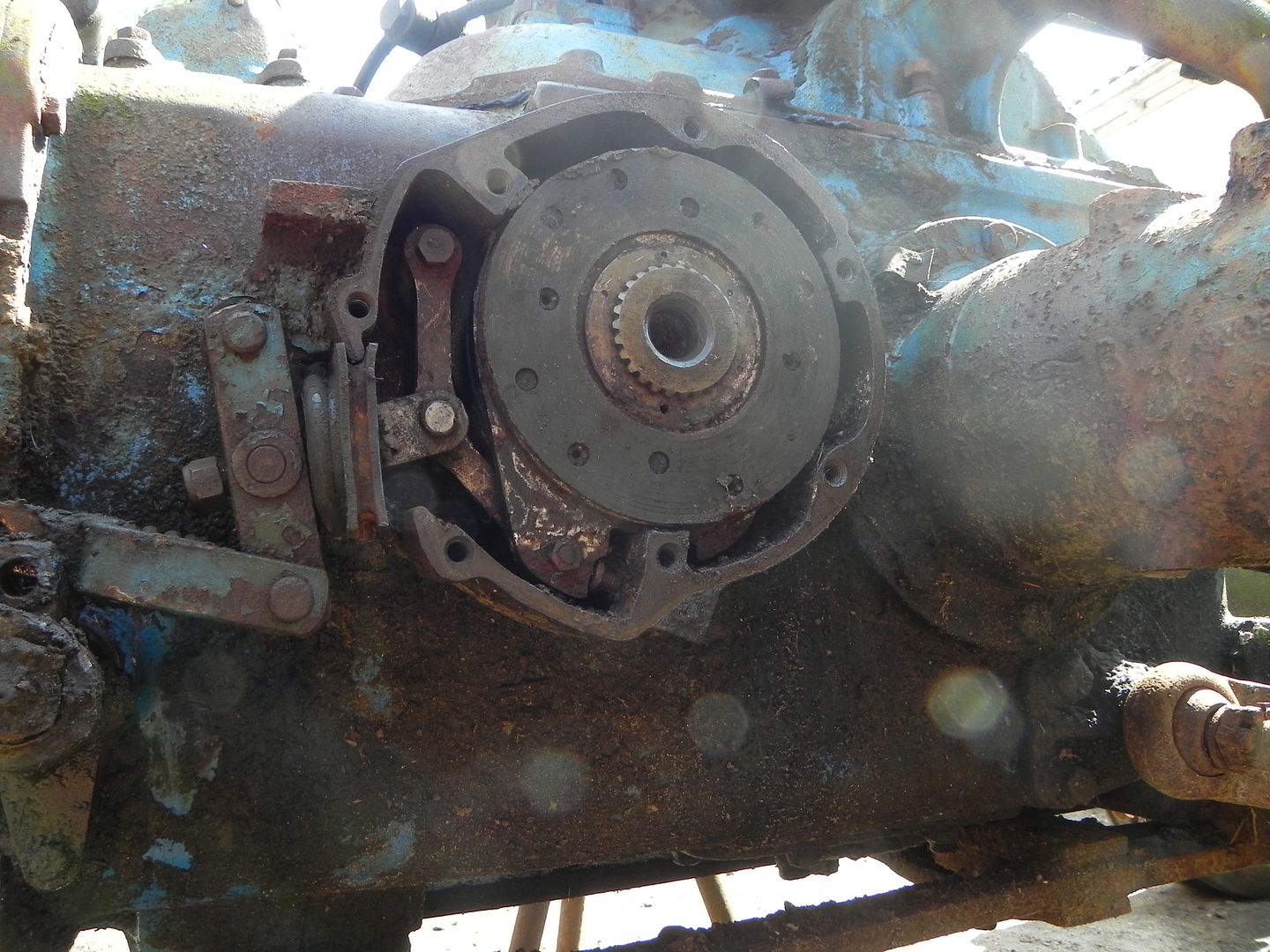

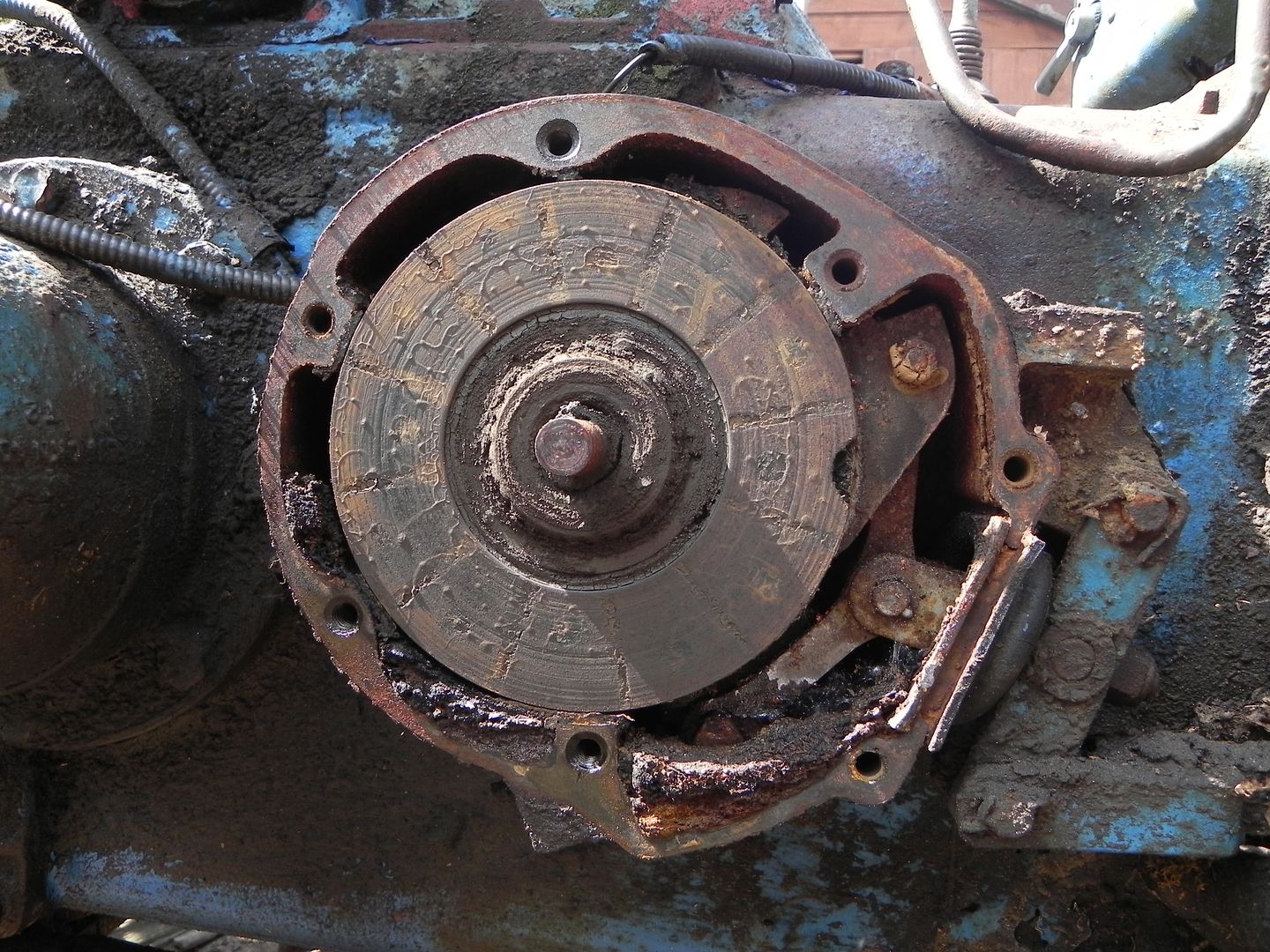

Now we can see why they do not work! And I cannot move the discs from the splines yet.

She had been fitted with a loader on a mixed farm so there would have been a fair bit of animal related substaces embedded in all the crevasses and this is what caused the rot to set in. It has also seized all the linkages and the dif.lock pedal.

not to mention the rust in the front cowl.

So over the next few months (or years) I will be stripping and repairing Super Sue. I intend to sort the rear axle first then move on to the engine. With any luck, I can get the engine into my workshop this winter and have it ready to go back early in 2012.

Anyone got a spare Super Major front cowl or wings that they do not need?

18.08.2011

Some progress today, with my four friends, Big Hammer, Big Punch, Big Wrecking Bar and Even Bigger Wrecking Bar I managed to get the brakes to pieces.

She will need new discs but there may be bits to save in the actuators.

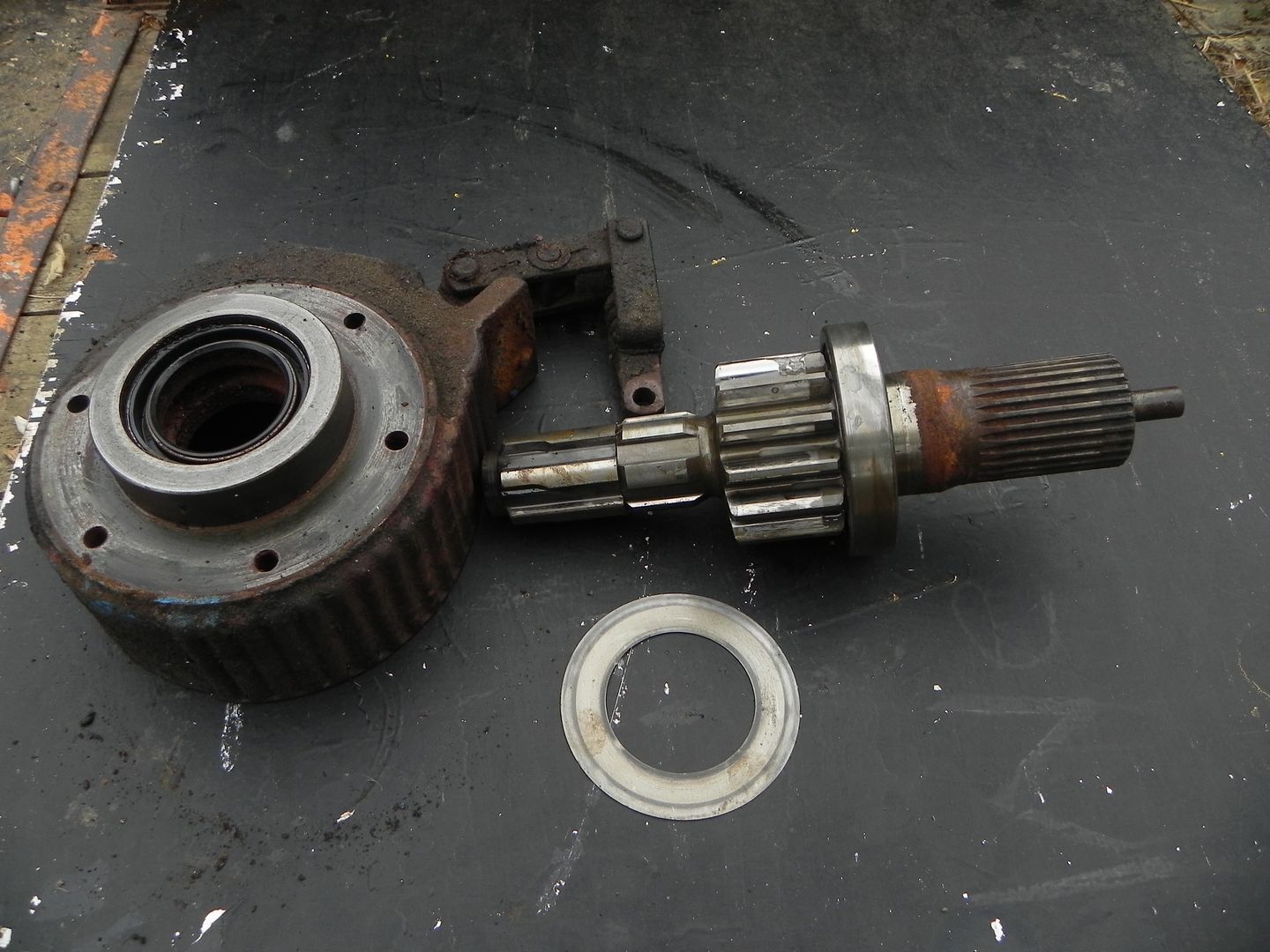

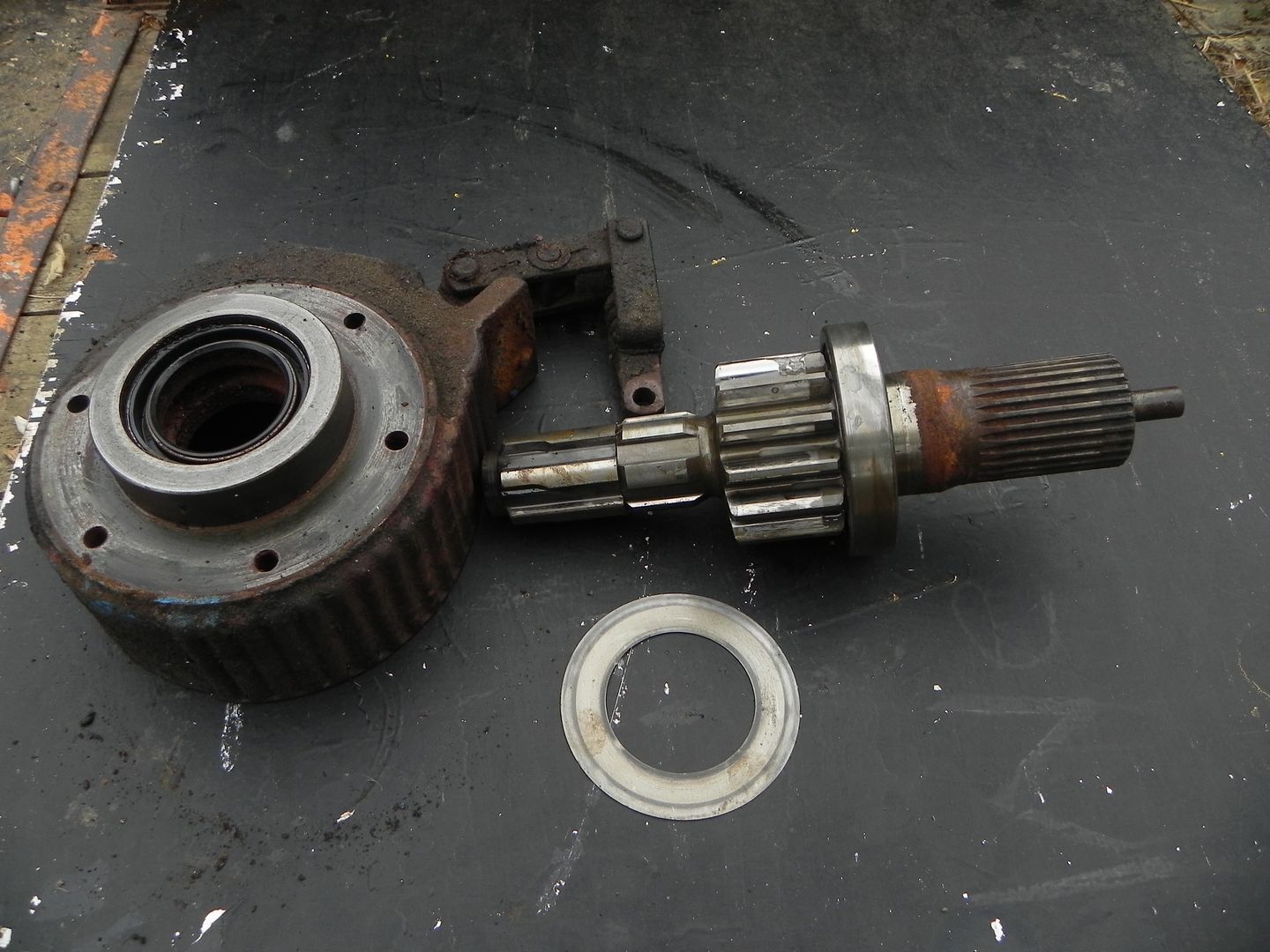

Brake housings were next to come off and by gently tapping the dif. carrier housings and at the same time pulling on the shaft, I removed the bull pinion shafts.

The right hand one also has the dif. lock as well.

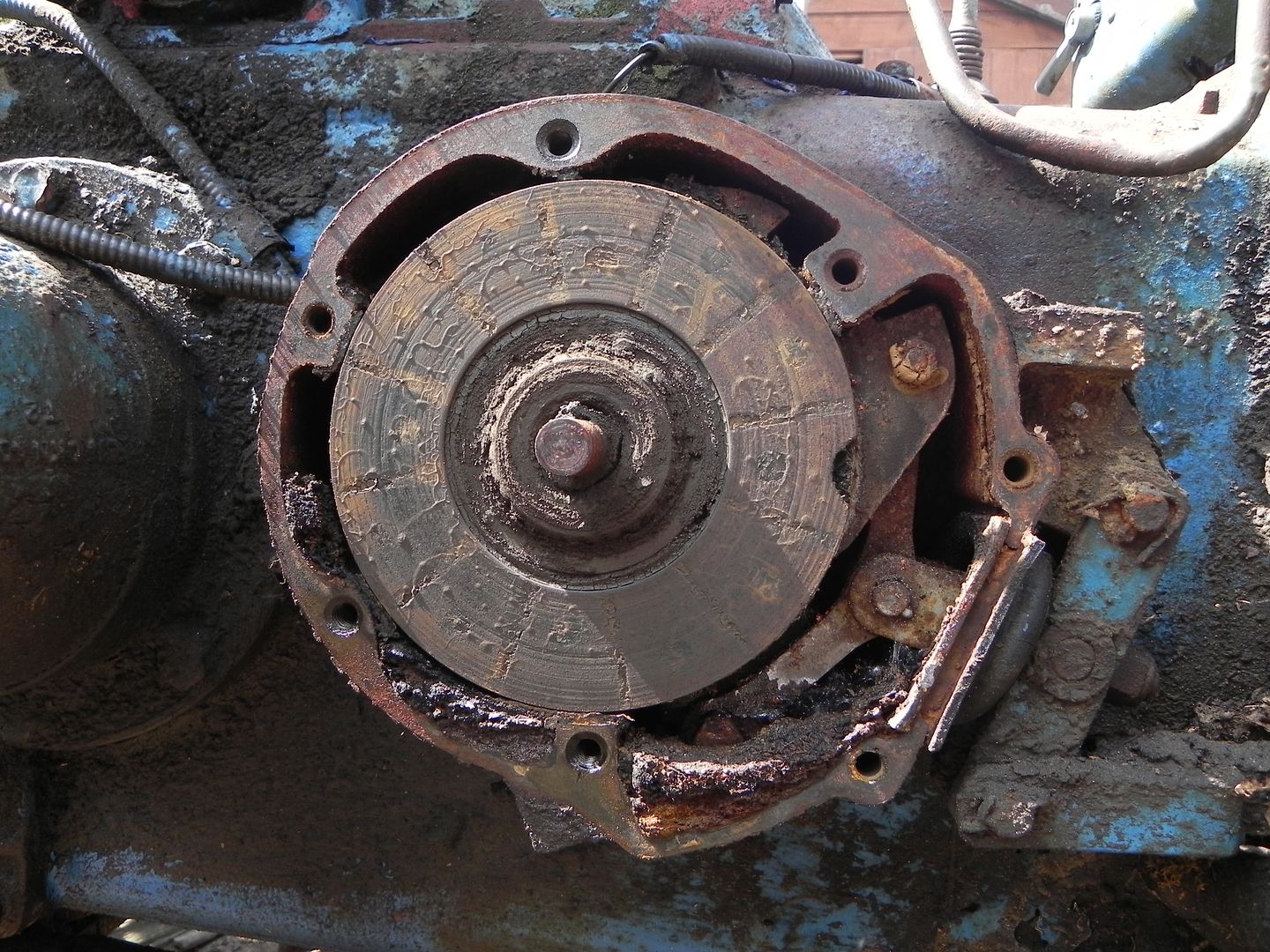

On checking the teeth on the bull pinion shaft I found an all to familiar problem.

The hard coating is worn on the teeth and they are starting to break up. This is a common problem with Supers, when ever we went out to a lift problem we always checked the state of the bull pinion gears and shafts. Sometimes, all you needed to do was gently run your fingers around the hydraulic pump intake ports in the pump pedestal. Here you would find all the broken facing and teeth. Metal particles in the oil would also score the ram cylinder and these would have to be replaced too.

I shall have to look for a bull pinion shaft as well as the tinwork.

On removing the lift to free the unload valve I found she had been fitted with a new ram cylinder just before she was stood up so that was a good sign.

Note the lifting ring for the crane.

Oil is milky due to water but all else is lovely and clean.

Lift upside down on the bench.

Stuck unload valve. PLEASE NOTE: Do not drive unload valve and plug out from here with a punch! The punch is only used as a pointer. I pulled the plug using an old socket and a bolt threaded into the plug.

The unload valve and unload valve plug. Note the later style piston ring. When fitting these type extreme care has to be taken not to break the cast ring. I hold them in place with thick grease. There is a special tool.

With the lift working and the engine running I put her on various implements over the next year to give her a workout. I found that she had oil leaks from both side axle shafts, a gear lever that turns completely round 360 degrees, an engine that smokes like a train under full load although this did dissipate as she worked, and the reason for the pipe fitted to the timing cover breather, as on the first day vast amounts of oil poured from here all over the front wheel. This again cleared as she worked on the plough and our big cultivator.

All in all, the engine pulled like a train in work, with no gearbox problems other than the usual noise. She had no brakes, these were seized solid but not stuck on, terminal rot had set into the wings and cowl, she had odd wheels but had all the other basic components like dash panel and covers.

According to all the casting codes and serial number, she is totally original so that fact also coloured my decision to renovate.

After making the decision to move a little further into restoration mode, I too parked her up and left her on our field. It was a case of out of sight, out of mind, until this year when we cleared the hay and I saw her looking all forlorn, I grasped the nettle and started on the full restoration.

We towed her home behind Rover, (this time I made sure Ann was in Low Box as a Super is unsafe at speeds of over 60 mph)

First job was to get the wheels and wings off then get rid of the Flatford Safety frame. This had been "bodged" on and had been the cause of damage to the footplates due to stretching the wings to fit after raising them up 1" on top of the frame mounting plates. Once this was done the tractor gained at least £100 in value just by looks alone.

Next job was to remove the footplates and put to one side whilst I check the disc brakes.

Now we can see why they do not work! And I cannot move the discs from the splines yet.

She had been fitted with a loader on a mixed farm so there would have been a fair bit of animal related substaces embedded in all the crevasses and this is what caused the rot to set in. It has also seized all the linkages and the dif.lock pedal.

not to mention the rust in the front cowl.

So over the next few months (or years) I will be stripping and repairing Super Sue. I intend to sort the rear axle first then move on to the engine. With any luck, I can get the engine into my workshop this winter and have it ready to go back early in 2012.

Anyone got a spare Super Major front cowl or wings that they do not need?

18.08.2011

Some progress today, with my four friends, Big Hammer, Big Punch, Big Wrecking Bar and Even Bigger Wrecking Bar I managed to get the brakes to pieces.

She will need new discs but there may be bits to save in the actuators.

Brake housings were next to come off and by gently tapping the dif. carrier housings and at the same time pulling on the shaft, I removed the bull pinion shafts.

The right hand one also has the dif. lock as well.

On checking the teeth on the bull pinion shaft I found an all to familiar problem.

The hard coating is worn on the teeth and they are starting to break up. This is a common problem with Supers, when ever we went out to a lift problem we always checked the state of the bull pinion gears and shafts. Sometimes, all you needed to do was gently run your fingers around the hydraulic pump intake ports in the pump pedestal. Here you would find all the broken facing and teeth. Metal particles in the oil would also score the ram cylinder and these would have to be replaced too.

I shall have to look for a bull pinion shaft as well as the tinwork.