No oil up top

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

No oil up top

I’m having a problem with my Selene/power Major, I am getting almost no oil to the top of the engine. This is the engine with the cam bearings and the McIvor’d main bearing shims. I had a exhaust valve stick one day so I pulled the rocker cover off to find everything up top mostly dry. It had 40 psi oil pressure but I pulled the pump off, shimmed the relief valve spring up, ended up with 60psi, still no oil up top. I pulled the rocker shaft off, swung the center stand out of the way and bolted it back down, started it up and got nothing more than a little gurgle out of the oil port in the head.

I then thought my main bearing shim had came loose and blocked off the oil port…..nope, not to mention that the oil to the cam bearing travels partly through the grove machined in the center of the bearing seat in the block, maybe the cam bearing had spun and blocked the port….nope, all the ports and bearings are open and lined up. I took the cam bearing out, set it on the cam, the holes in the bearing line up perfectly with the port in the cam.

As I am writing this it occurs to me I need to go check the alignment of the cam ports back and forth…and check the cam end play to make sure the ports aren’t misaligned sideways.

Anyone have this problem before or have any good ideas?

Pat

I then thought my main bearing shim had came loose and blocked off the oil port…..nope, not to mention that the oil to the cam bearing travels partly through the grove machined in the center of the bearing seat in the block, maybe the cam bearing had spun and blocked the port….nope, all the ports and bearings are open and lined up. I took the cam bearing out, set it on the cam, the holes in the bearing line up perfectly with the port in the cam.

As I am writing this it occurs to me I need to go check the alignment of the cam ports back and forth…and check the cam end play to make sure the ports aren’t misaligned sideways.

Anyone have this problem before or have any good ideas?

Pat

Re: No oil up top

Hi Pat

Just wondering if there is a chunk of white metal from a previous bearing failure lodged up an oil gallery some where restricting flow I have heard of a Case 2290 and a Versatile 4wd seize a crank bearing shortly after a re build from this problem

I have heard of a Case 2290 and a Versatile 4wd seize a crank bearing shortly after a re build from this problem  .

.

Regards Robert

Just wondering if there is a chunk of white metal from a previous bearing failure lodged up an oil gallery some where restricting flow

Regards Robert

A Fordson is for life not just for Christmas !.

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: No oil up top

Also wondering if someone left out an oil galley plug somewhere??? I always pull them and clean the galleys when doing any complete overhaul on any engine. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

Kiwi Kev

- Site Governance Team & Expert Team

- Posts: 802

- Joined: Thu Apr 17, 2008 7:44 am

- Location: Norfolk Island. South Pacific.

Re: No oil up top

Pat

Think I would be stripping that motor back to bare bones and as Dave says, clean everything out.

Then examine and put back together. At the very least it's only going to cost you your labour and gaskets. You will probably want to do rings and bearings etc also.

Shes a nice tractor, so if the engine is original, don't want to loose it.

Kiwi Kev

Think I would be stripping that motor back to bare bones and as Dave says, clean everything out.

Then examine and put back together. At the very least it's only going to cost you your labour and gaskets. You will probably want to do rings and bearings etc also.

Shes a nice tractor, so if the engine is original, don't want to loose it.

Kiwi Kev

"Classic Contracting"

66 Ford 5000 6X (semi retirement)

International 784 4WD

& looking at another tractor!

66 Ford 5000 6X (semi retirement)

International 784 4WD

& looking at another tractor!

-

Dons62FSM

- Not Quite Blue Yet

- Posts: 27

- Joined: Thu May 03, 2012 3:15 am

- Location: North Central Alabama, USA

Re: No oil up top

You might try pumping oil into the top passage with the oil pan (sump) off. That could tell you if there is a plug out or other leakage path. At one time an oil leakage tester was found in some shops. It was an oil container that could be plumbed into the oil gallery and pressurized with air. Was a really good tool for finding worn bearings, leaks, and blockages. It would also give you an idea of the pump condition, based on the amount of back leakage. Pressurizing the oil passages with just air might give you some idea of where your problem is.

Don Young

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

When I rebuilt this engine I had opened up the oil ports and cleaned them good, I always run a rod, wire brush, etc. through all the ports to make sure they are clean.

So when I got home from work yesterday I went up in the barn and grabbed a old Super Major cam I had, looked it over and realized it has two oil passages rather than one as the earlier cams have, apparently Ford had oiling issues up top as well.

I took the cam bearing I had out, marked the spots on the cam and drilled a second port in it, now it will get two squirts per revolution up top.

I took the shim out of the oil pump spring and slapped every thing back together just enough to run it. I started it up, had 40psi oil pressure, and still looked dry up top. I again swung the center rocker shaft stand out of the way, started it and this time I have nothing coming up.

When I slapped the front plate on the engine I didn’t put all the bolts in it, I may have oil squirting out of one of these , Ill pull the timing cover off and start it to verify, but I’m thinking I will have to pull the engine and pressurize the oil system to figure out what is going on. As this block had been line board and cam bearings installed there may be some issues that cased the original failure that have never been resolved.

My kid’s boss mentioned that Leland had a few issues with internal ports in the blocks cracking/breaking and loosing oil.

Pat

So when I got home from work yesterday I went up in the barn and grabbed a old Super Major cam I had, looked it over and realized it has two oil passages rather than one as the earlier cams have, apparently Ford had oiling issues up top as well.

I took the cam bearing I had out, marked the spots on the cam and drilled a second port in it, now it will get two squirts per revolution up top.

I took the shim out of the oil pump spring and slapped every thing back together just enough to run it. I started it up, had 40psi oil pressure, and still looked dry up top. I again swung the center rocker shaft stand out of the way, started it and this time I have nothing coming up.

When I slapped the front plate on the engine I didn’t put all the bolts in it, I may have oil squirting out of one of these , Ill pull the timing cover off and start it to verify, but I’m thinking I will have to pull the engine and pressurize the oil system to figure out what is going on. As this block had been line board and cam bearings installed there may be some issues that cased the original failure that have never been resolved.

My kid’s boss mentioned that Leland had a few issues with internal ports in the blocks cracking/breaking and loosing oil.

Pat

-

roadless J17

- Not Quite Blue Yet

- Posts: 25

- Joined: Tue Mar 01, 2011 11:44 am

Re: No oil up top

hi how good is the condition of the horse shoe which holds the cam back in place and is the new cam bush poshed in enough to meet the hole in the cam

tom

tom

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

Hi Tom, The horse shoe looks good, very little end play, and the ports in the cam line up properly with the holes in the bearings.

I had a little time Friday and we started it up with the timing gear cover off, it looked like there was a horrendous amount of oil coming from around the front cam bearing. When I rebuilt it I reused the cam bearings as none are available and I have a bad feeling that they are no longer usable. I’m thinking we may make some replacement bearing from brass. As I trashed the rear main seal from taking the oil pan on and off, we will take the engine out regardless and I plan on pressurizing the oil system as the guys suggested to look for leaks or to verify bad bearings and also recheck all passages for possible blockages.

Pat

I had a little time Friday and we started it up with the timing gear cover off, it looked like there was a horrendous amount of oil coming from around the front cam bearing. When I rebuilt it I reused the cam bearings as none are available and I have a bad feeling that they are no longer usable. I’m thinking we may make some replacement bearing from brass. As I trashed the rear main seal from taking the oil pan on and off, we will take the engine out regardless and I plan on pressurizing the oil system as the guys suggested to look for leaks or to verify bad bearings and also recheck all passages for possible blockages.

Pat

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: No oil up top

Turn new bushings from oilite Bronze. Not Brass. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

Got the engine off and on a stand last night, flipped it over and started looking around with a flashlight and a mirror inside of the block, everything looks good so far. If I get time tonight I’ll hook a pump to the block and push some oil through it, hopefully I will be able to see where the problem is.

I opened my fat mouth at the St Mary’s sauerkraut festival last year and suggested they have a tractor show….and was later elected to put the show on…..mysteriously I was not invited to that particular meeting , so it is going to be another busy weekend that started already last night, I may not get back to the Selene till next week.

, so it is going to be another busy weekend that started already last night, I may not get back to the Selene till next week.

Pat

I opened my fat mouth at the St Mary’s sauerkraut festival last year and suggested they have a tractor show….and was later elected to put the show on…..mysteriously I was not invited to that particular meeting

Pat

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

Tonight I got a chance to tap into the port alongside of the oil pump with an external pump, I had to drill a hole in the pump housing to get the oil to flow through but this way I am duplicating the existing system by flowing through all of the ports, passages, and the filter. After I gave the ceiling a fairly good oil job I threw a rag over the pressure relief on the oil pump as I couldn’t throttle down my external pump enough, I’ll probably put a ball valve in the discharge side as the external pump is equipped with a pressure bypass as well.

I expected to see oil running out of the cam bearings like crazy but this was not the case, actually it looked like I had more coming out from around the crank. Now I am back to thinking I have a blockage in an oil port, and again wondering if there is an unresolved issue with this block that caused it to fail when it was line bored and rebuilt the first time.

Pat

I expected to see oil running out of the cam bearings like crazy but this was not the case, actually it looked like I had more coming out from around the crank. Now I am back to thinking I have a blockage in an oil port, and again wondering if there is an unresolved issue with this block that caused it to fail when it was line bored and rebuilt the first time.

Pat

-

Dons62FSM

- Not Quite Blue Yet

- Posts: 27

- Joined: Thu May 03, 2012 3:15 am

- Location: North Central Alabama, USA

Re: No oil up top

You might try a rubber tipped blowgun or similar air connection into the rocker feed. Whether any air escapes and if so, where, could help without further teardown.

It would be nice if you could post a diagram of the oiling system, once you have it figured out, as I assume one is not readily available. I have heard of engines that oiled the rockers from the relief valve, the idea apparently being to not starve the lower end if pressure was low. On some engines people have blocked the rocker feed by not installing a hollow bolt in the proper hole, reversing the head gasket, and similar mistakes.

It would be nice if you could post a diagram of the oiling system, once you have it figured out, as I assume one is not readily available. I have heard of engines that oiled the rockers from the relief valve, the idea apparently being to not starve the lower end if pressure was low. On some engines people have blocked the rocker feed by not installing a hollow bolt in the proper hole, reversing the head gasket, and similar mistakes.

Don Young

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

Re: No oil up top

If my memory serves me right, I seem to remember that some engines had their feed to the top end via a hole in a camshaft shell bearing. If this were not fitted correctly then, obviously, there would be no oil feed.

Just a thought.

Pavel

Just a thought.

Pavel

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: No oil up top

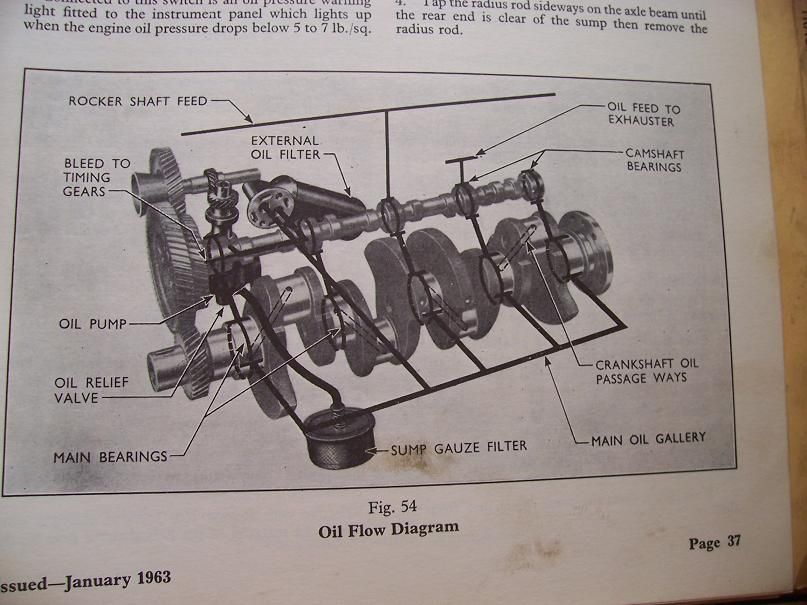

I've worked on Ford industrial, truck, and car engines that have the hole in the bolt. From my Fordson Servicemens Book....

Dandy Dave!

Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

Found it….and I got no one to blame but myself!

This is the engine with the main bearing shims that I Loctited in place, today I checked a few more things and then pulled the crank. When I popped the main bearing from the block I found the villain….Green Loctite, it had pooled up in the oil passage and set, quite effectively blocking that passage tight. Oil was still moving through the passage in the cap and through the bearing on the crank side, but was not flowing enough on the center main to get proper oil up top. Luckily it looks like nothing was ruined as long as the valve guides aren’t trashed.

Dave, thanks for the oil diagram, I have it in my manuals as well but I'm sure their are plenty of readers that don't!

Pat

This is the engine with the main bearing shims that I Loctited in place, today I checked a few more things and then pulled the crank. When I popped the main bearing from the block I found the villain….Green Loctite, it had pooled up in the oil passage and set, quite effectively blocking that passage tight. Oil was still moving through the passage in the cap and through the bearing on the crank side, but was not flowing enough on the center main to get proper oil up top. Luckily it looks like nothing was ruined as long as the valve guides aren’t trashed.

Dave, thanks for the oil diagram, I have it in my manuals as well but I'm sure their are plenty of readers that don't!

Pat

Last edited by BearCreek Majors on Tue Aug 07, 2012 4:06 pm, edited 1 time in total.

-

Dons62FSM

- Not Quite Blue Yet

- Posts: 27

- Joined: Thu May 03, 2012 3:15 am

- Location: North Central Alabama, USA

Re: No oil up top

Glad you found the problem and let us know what it was. I have shimmed quite a few bearings (not Fordson) in my day but have never thought of using Loctite to retain them. I don't see how a shim could move as long as the shells are tight and if they move any the job is doomed from the start. I would be interested to know your reason for using the Loctite.

Although it is possible, I doubt that your valve guides are damaged. I am sure you lubricated them when you installed the valves and valve guides generally operate with very little oil. I would suspect that lack of oil would damage the rockers before the valves or guides.

Although it is possible, I doubt that your valve guides are damaged. I am sure you lubricated them when you installed the valves and valve guides generally operate with very little oil. I would suspect that lack of oil would damage the rockers before the valves or guides.

Don Young

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: No oil up top

Glad to post the oil flow photo for those that do not have it.

I have to agree that the valves are most likely fine. I've worked on a lot of early stationary engines with an open crank, push rods, and valves. It always amazed me that with a little grease in the cups for the mains and rod, a few drops of oil on the valve train, and about one drip every ten seconds from a sight glass oiller for the piston and cylinder, that these engines would run for hours. It was more likely that a valve would stick, usually an exhaust, from lack of lube and carbon build up than wear the guides out anytime quickly. Even today in many of the engines the only lube that the valves and guides seem to get is whatever oil mist floating around in the engine that sticks to the stems. Look at the Fordson F for an example. The valves are in it so the mist sticks to them and hopfully works it's way up the stem as the valves works up and down. Thousands of operating hours in the field on these early tractors is the proof. Dandy Dave!

I have to agree that the valves are most likely fine. I've worked on a lot of early stationary engines with an open crank, push rods, and valves. It always amazed me that with a little grease in the cups for the mains and rod, a few drops of oil on the valve train, and about one drip every ten seconds from a sight glass oiller for the piston and cylinder, that these engines would run for hours. It was more likely that a valve would stick, usually an exhaust, from lack of lube and carbon build up than wear the guides out anytime quickly. Even today in many of the engines the only lube that the valves and guides seem to get is whatever oil mist floating around in the engine that sticks to the stems. Look at the Fordson F for an example. The valves are in it so the mist sticks to them and hopfully works it's way up the stem as the valves works up and down. Thousands of operating hours in the field on these early tractors is the proof. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

Hi Don, the reason for Loctite, the shim stock I used was .007, the bore is .015 over, thus I am .001 loose on the shim from the start. Years ago there was a company that made shim assortment for doing a “poor mans” rebuild and I remember hearing that these shims would work loose and walk out from under the bearing insert, with this in the back of my head I decided to use the Loctite just to make sure the shims would not move. This time I just wiped the Loctite on with a Qtip.

Last night I finished slapping the engine together and stuck it back on the tractor enough to start it. I now have oil up top but still not enough to push it through the bleed holes in the rockers or anywhere else to lube the valves. Thinking I had found the smoking gun I didn’t bother looking anywhere else, looks like I’m going to rip it down again.

Pat

Last night I finished slapping the engine together and stuck it back on the tractor enough to start it. I now have oil up top but still not enough to push it through the bleed holes in the rockers or anywhere else to lube the valves. Thinking I had found the smoking gun I didn’t bother looking anywhere else, looks like I’m going to rip it down again.

Pat

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

I finally got it!

I now know why this thing was sitting in a junkyard, the previous owner probably gave up on it, I thought it was odd that the internals were mostly fresh but bad from sitting out on the open.

And as much as I don’t want to I am going to blame Ford for this failure.

The oil ports in the camshaft didn’t line up with the holes in the cam bearings, actualy the holes in the bearings were just to damn small. And if I’d taken two more minutes to look everything over the last time I was in there I wouldn’t have had to rip it apart again.

The old cam has a port through the journal offset from the center axis to align with the oil passages in the block when at the proper orientation of its revolution. It also has a slight countersunk connected to the port on one end, I mistakenly assumed this was a modification to start the flow of oil into the port of the cam to give it a “precharge” before the other side opened up to the rocker shaft oil passage. Actually the port in the cam lines up directly with the auxiliary oil passage for use with attachments mounted behind the injector pump, ironically this passage is not in the center boss of the block but in the next one back, so ….when the port in the cam has gone by the rocker passage and is on its way to the aux passage the pressure/feed ports/passage are just starting to open up to each other, and the countersink is almost gone past the rocker passage, there is just enough of a “window” to let a little oil through this arrangement. Seems rather marginal to me and apparently to Ford as well. Hence the modified Super Major cam, but……not paying attention I assumed the Super cam merely had another port parallel with the first…..Wrong! After I stuck a wire in the holes last night I realized that the ports are drilled in an X pattern not parallel, thus giving one shot to the aux passage and one shot to the rocker passage per revolution. The second parallel port I drilled did nothing as it merely lined up with the non existing aux passage giving it two shots per revolution.

SO..the problem with my engine……the holes in the cam bearings are smaller than the passages in the block…..thus the “window” never opens.

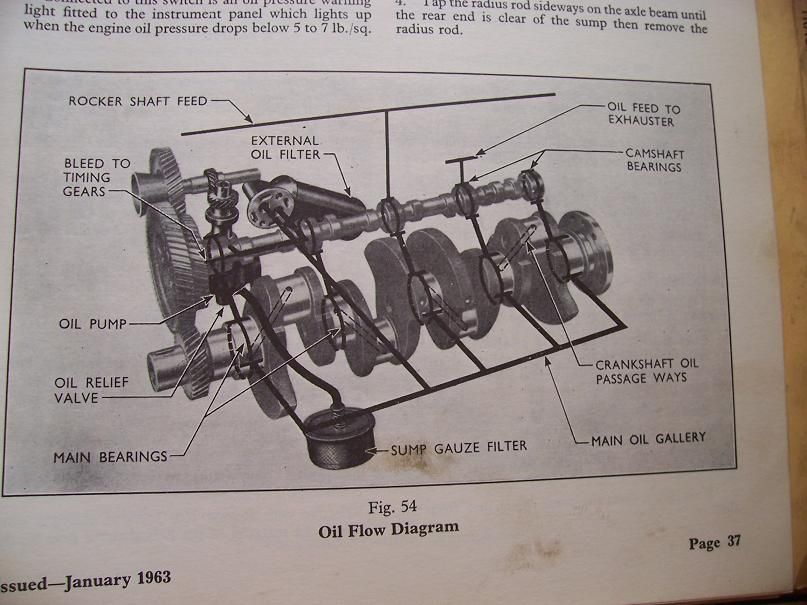

You can see how much larger the outline of the blocks oil passage is compared to the hole in the bearing in the pic.

Pat

I now know why this thing was sitting in a junkyard, the previous owner probably gave up on it, I thought it was odd that the internals were mostly fresh but bad from sitting out on the open.

And as much as I don’t want to I am going to blame Ford for this failure.

The oil ports in the camshaft didn’t line up with the holes in the cam bearings, actualy the holes in the bearings were just to damn small. And if I’d taken two more minutes to look everything over the last time I was in there I wouldn’t have had to rip it apart again.

The old cam has a port through the journal offset from the center axis to align with the oil passages in the block when at the proper orientation of its revolution. It also has a slight countersunk connected to the port on one end, I mistakenly assumed this was a modification to start the flow of oil into the port of the cam to give it a “precharge” before the other side opened up to the rocker shaft oil passage. Actually the port in the cam lines up directly with the auxiliary oil passage for use with attachments mounted behind the injector pump, ironically this passage is not in the center boss of the block but in the next one back, so ….when the port in the cam has gone by the rocker passage and is on its way to the aux passage the pressure/feed ports/passage are just starting to open up to each other, and the countersink is almost gone past the rocker passage, there is just enough of a “window” to let a little oil through this arrangement. Seems rather marginal to me and apparently to Ford as well. Hence the modified Super Major cam, but……not paying attention I assumed the Super cam merely had another port parallel with the first…..Wrong! After I stuck a wire in the holes last night I realized that the ports are drilled in an X pattern not parallel, thus giving one shot to the aux passage and one shot to the rocker passage per revolution. The second parallel port I drilled did nothing as it merely lined up with the non existing aux passage giving it two shots per revolution.

SO..the problem with my engine……the holes in the cam bearings are smaller than the passages in the block…..thus the “window” never opens.

You can see how much larger the outline of the blocks oil passage is compared to the hole in the bearing in the pic.

Pat

-

Dons62FSM

- Not Quite Blue Yet

- Posts: 27

- Joined: Thu May 03, 2012 3:15 am

- Location: North Central Alabama, USA

Re: No oil up top

Well, it seems like you have finally solved it with a lot of really good thought and checking. It is amazing how something which seems like it should work just doesn't because of some problem which is hard to see. One normally assumes that passages that are supposed to line up actually do.

Don Young

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

1962 US Super Major

712 Industrial Loader

723 14' Backhoe

Leyland 472, JD 420U, IH Cubs

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: No oil up top

Not the first time I've had to deal with factory defects also. Shhhtuff just happens, even on the production line. Glad you have it sorted.  Dandy Dave!

Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

Kiwi Kev

- Site Governance Team & Expert Team

- Posts: 802

- Joined: Thu Apr 17, 2008 7:44 am

- Location: Norfolk Island. South Pacific.

Re: No oil up top

Pat

Glad you found the problem.

So the bearing AND the loctite was the problem, or just the bearing.

What's the remedy for the bearing? Drill or slot the oil hole to match the cam

Kiwi Kev

Glad you found the problem.

So the bearing AND the loctite was the problem, or just the bearing.

What's the remedy for the bearing? Drill or slot the oil hole to match the cam

Kiwi Kev

"Classic Contracting"

66 Ford 5000 6X (semi retirement)

International 784 4WD

& looking at another tractor!

66 Ford 5000 6X (semi retirement)

International 784 4WD

& looking at another tractor!

-

BearCreek Majors

- True Blue

- Posts: 793

- Joined: Tue Jul 21, 2009 3:16 am

- Location: Wisconsin USA

Re: No oil up top

I’d have to say the loctite was only a little of the problem if any at all, the oil was still able to move around the bearing cap only at less volume. In my mind I thought it was the smoking gun but in reality it probably had little to no effect.

The easiest fix would probably be to slot the holes in the bearing. As I had already drilled a extra passage in the cam I drilled one more short passage that connected it with the rocker galley, again similar to the Super Major cam. Also, the Super Major cam would not have the alignment issue as its extra port should line up exactly as needed.

Granny and I got her back together tonight and I ran it around a little. Everything looks good, 40 to 50psi oil pressure, and oil dripping off the rockers to the valves and pushrods. Tomorrow I hope to check the rotator cap clearance ( all four fell on the floor when I spun it over on the engine stand), set the valve lash, close it up and give her a bath. I doubt that she will get painted any more this summer, too much to get done as fall is on its way, but maybe later this fall or over the winter.

Pat

The easiest fix would probably be to slot the holes in the bearing. As I had already drilled a extra passage in the cam I drilled one more short passage that connected it with the rocker galley, again similar to the Super Major cam. Also, the Super Major cam would not have the alignment issue as its extra port should line up exactly as needed.

Granny and I got her back together tonight and I ran it around a little. Everything looks good, 40 to 50psi oil pressure, and oil dripping off the rockers to the valves and pushrods. Tomorrow I hope to check the rotator cap clearance ( all four fell on the floor when I spun it over on the engine stand), set the valve lash, close it up and give her a bath. I doubt that she will get painted any more this summer, too much to get done as fall is on its way, but maybe later this fall or over the winter.

Pat

Last edited by BearCreek Majors on Fri Aug 17, 2012 3:38 am, edited 1 time in total.

Re: No oil up top

Hi Pat

Glad you found all the problems I'll probably get nailed on a cross and roasted by the experts for saying this

I'll probably get nailed on a cross and roasted by the experts for saying this  But I have never checked rotor clearance on a major in my life, i have had motors in kit form and with rotors missing and as long as it had the correct style rotator just put one back on and set the lash. Ive never had a problem, maybe I have just been lucky.

But I have never checked rotor clearance on a major in my life, i have had motors in kit form and with rotors missing and as long as it had the correct style rotator just put one back on and set the lash. Ive never had a problem, maybe I have just been lucky.

I'm guessing that on a 60 year old motor they are gonna be worn anyway so they will probably work close enough .

Regards Robert

Glad you found all the problems

I'm guessing that on a 60 year old motor they are gonna be worn anyway so they will probably work close enough .

Regards Robert

A Fordson is for life not just for Christmas !.

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Re: No oil up top

Parts come off of a production line and are suppose to be the same within a required specification. If they are made correctly if should not be a problem. Even if a valve rotor is slighly worn the valve would not open as much by only few thousands of an inch. I've never seen where valve rotors were worn even that much though. Any time head and valve work is done, the valve lash needs to be checked prior to starting. And then rechecked after an initial running. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major