Page 1 of 1

Spool Valves.

Posted: Fri Nov 15, 2013 10:35 am

by Brian

Pictures of the various valves used throughout the world.

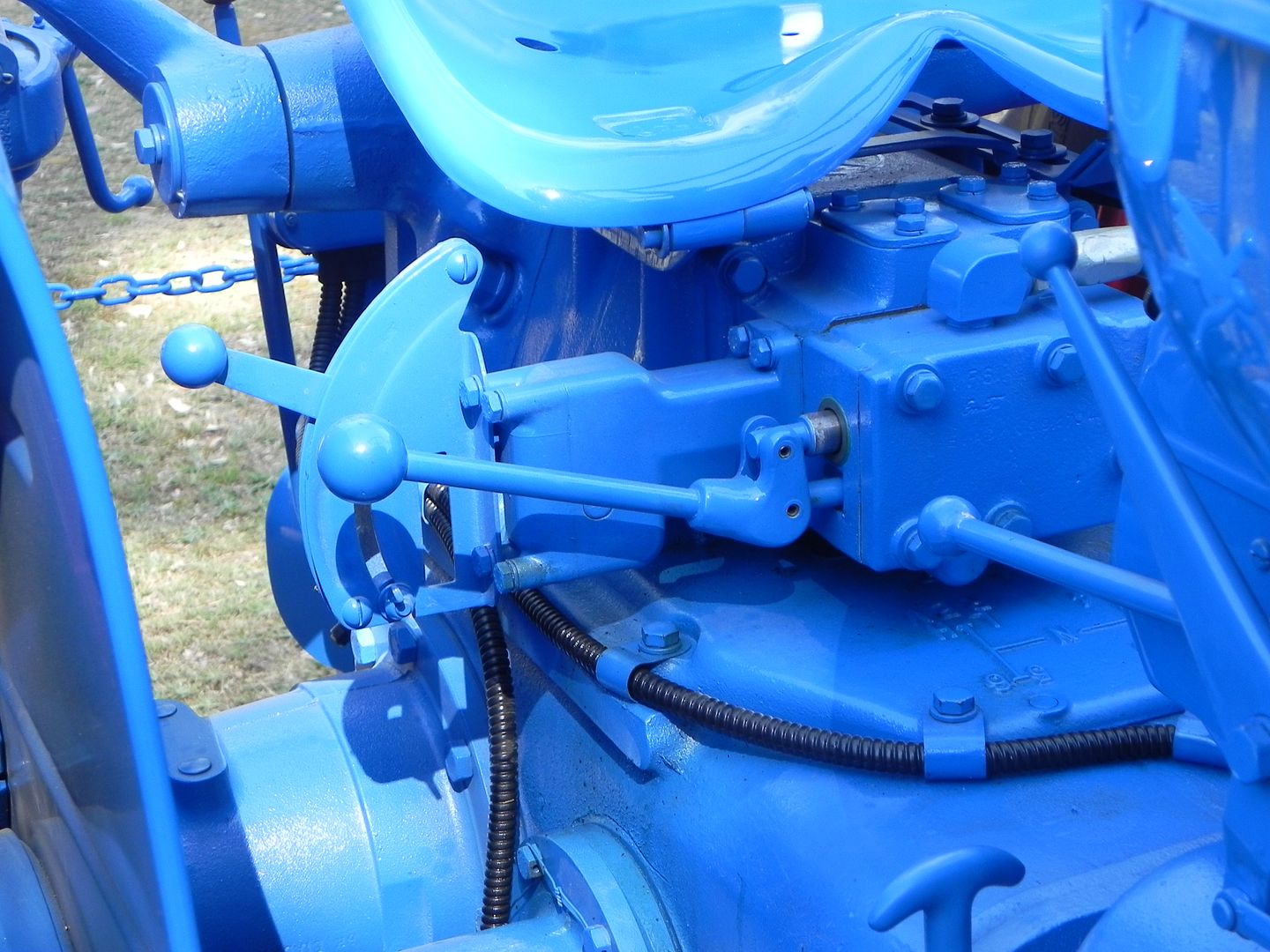

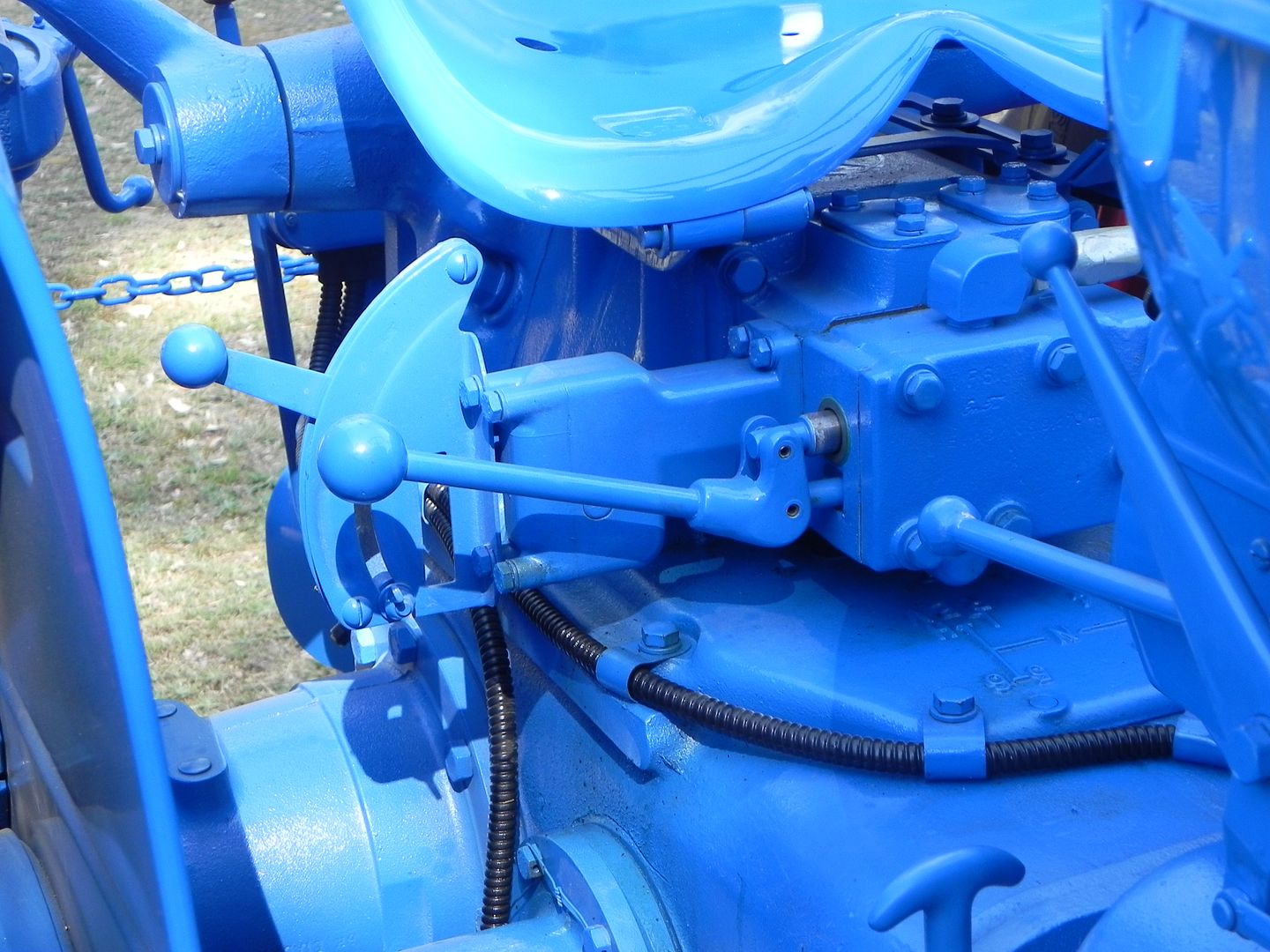

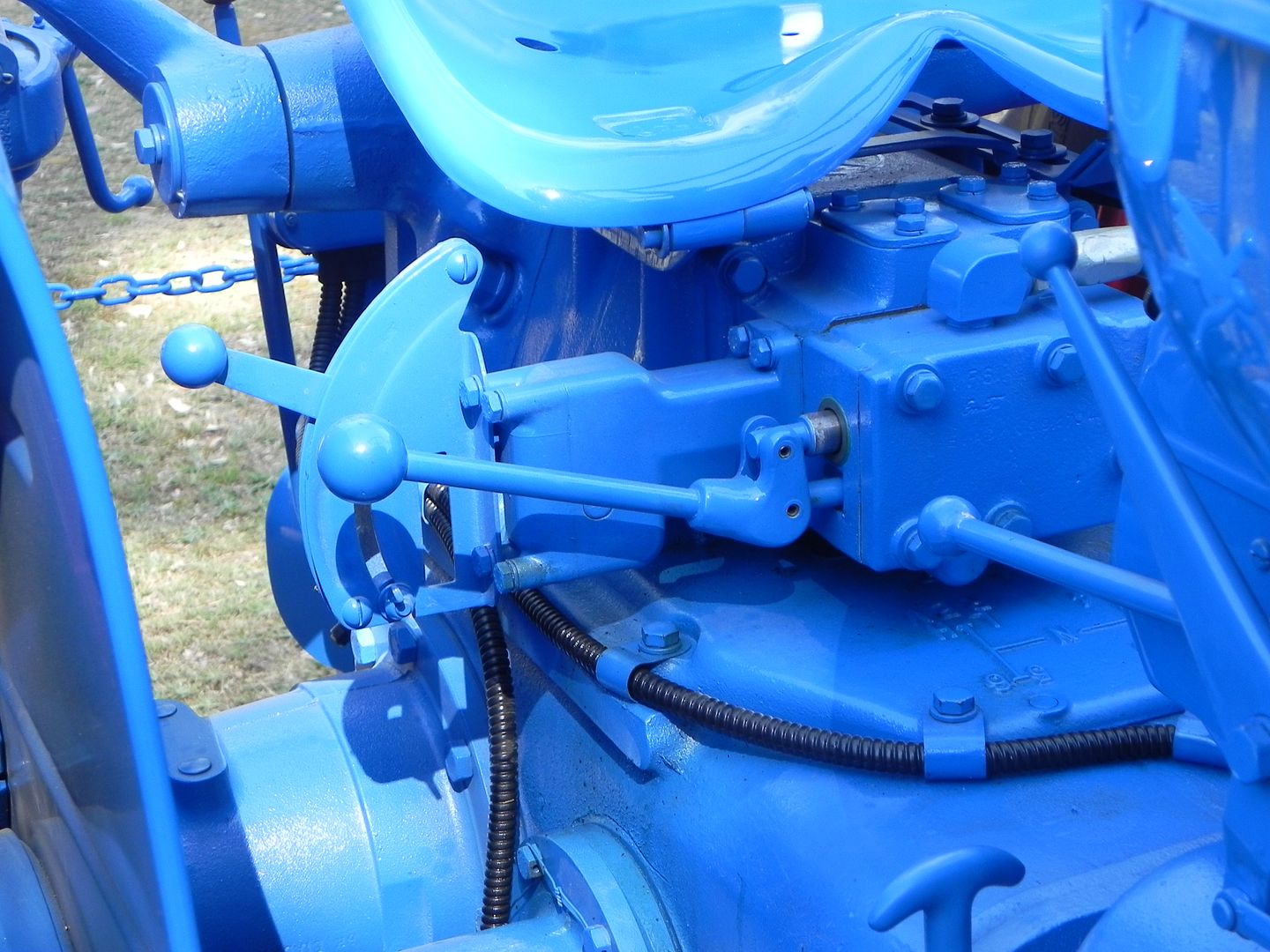

Major spool valve, Australia.

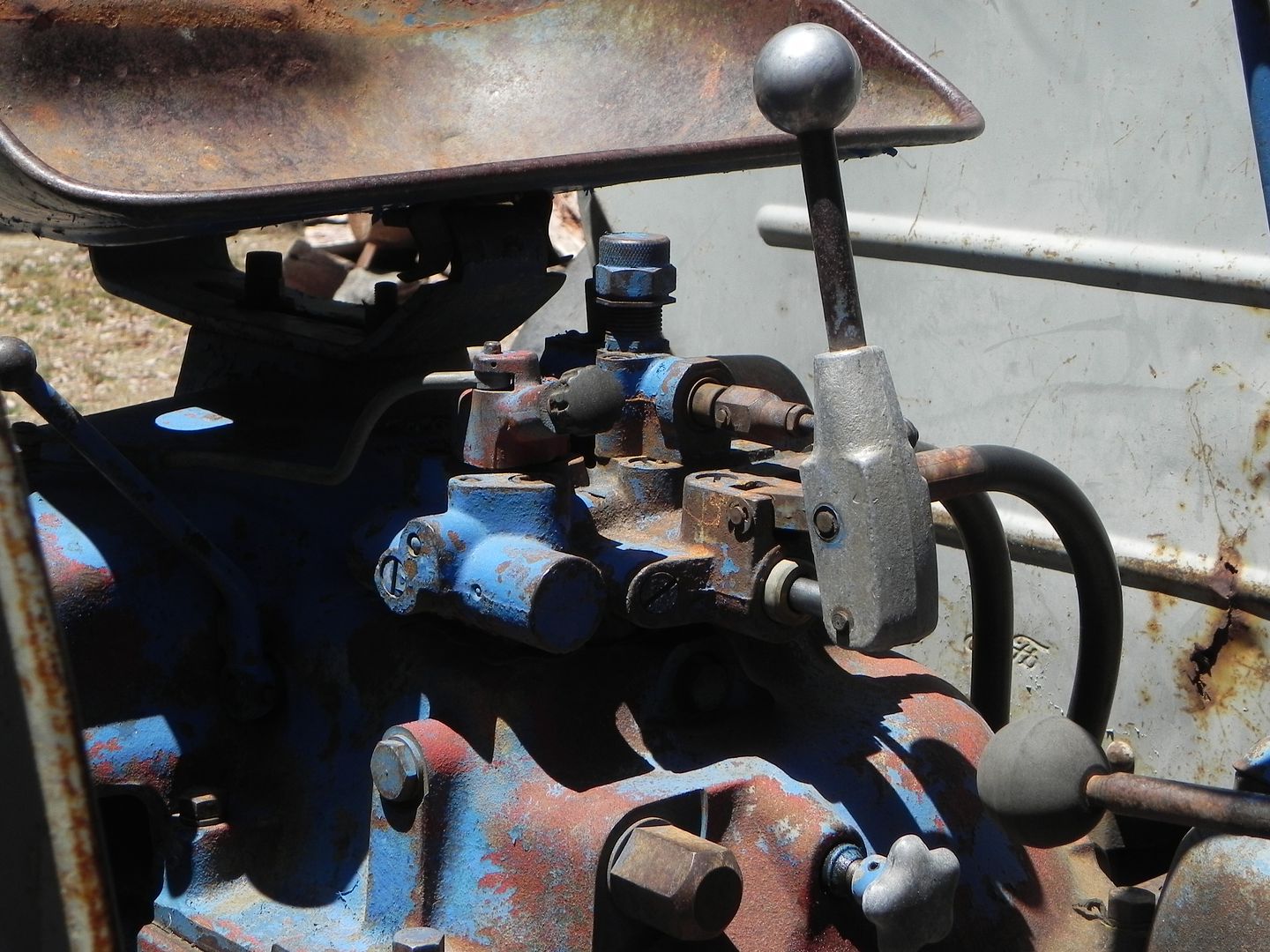

Super Major spool valve, Australia.

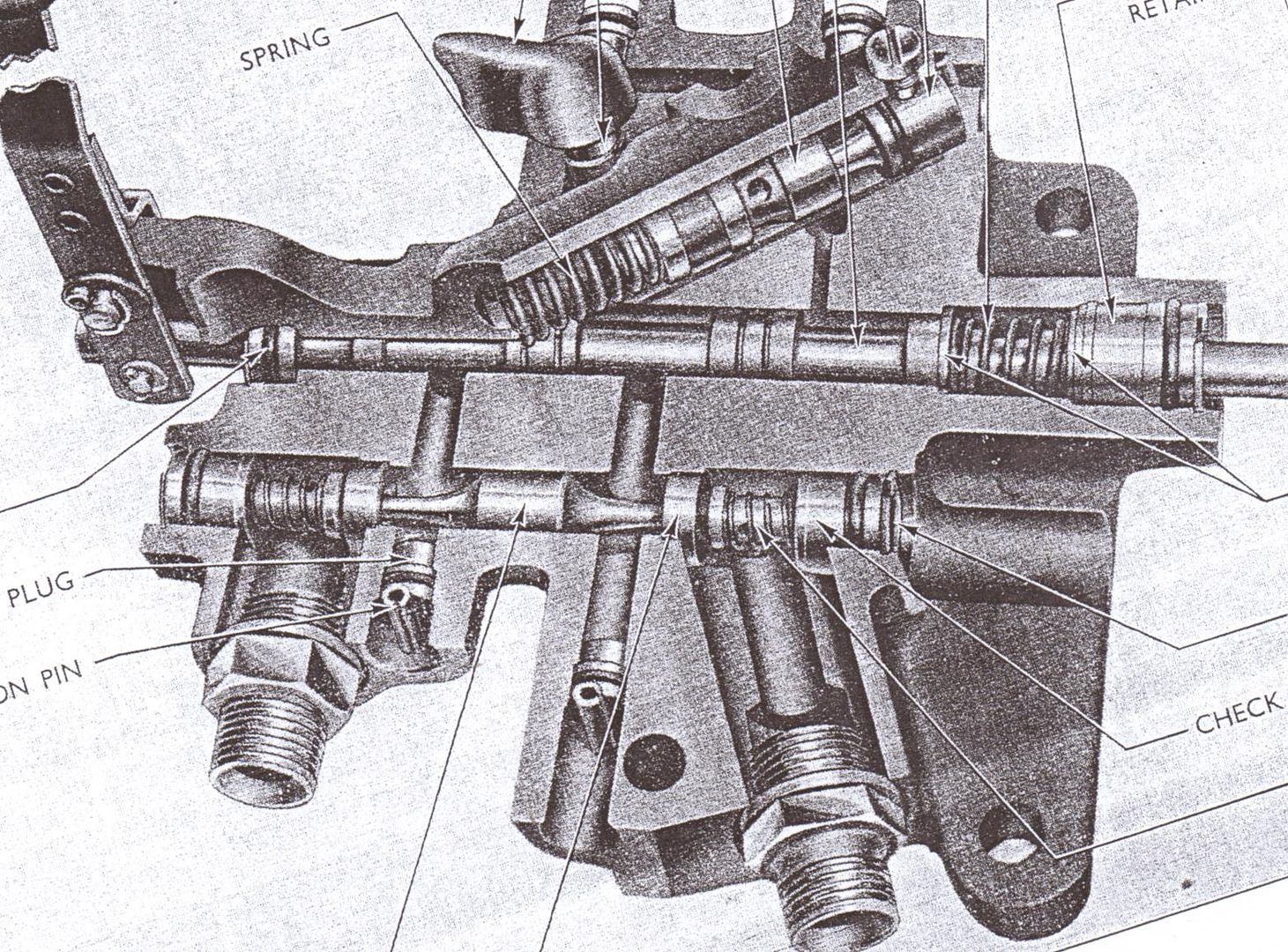

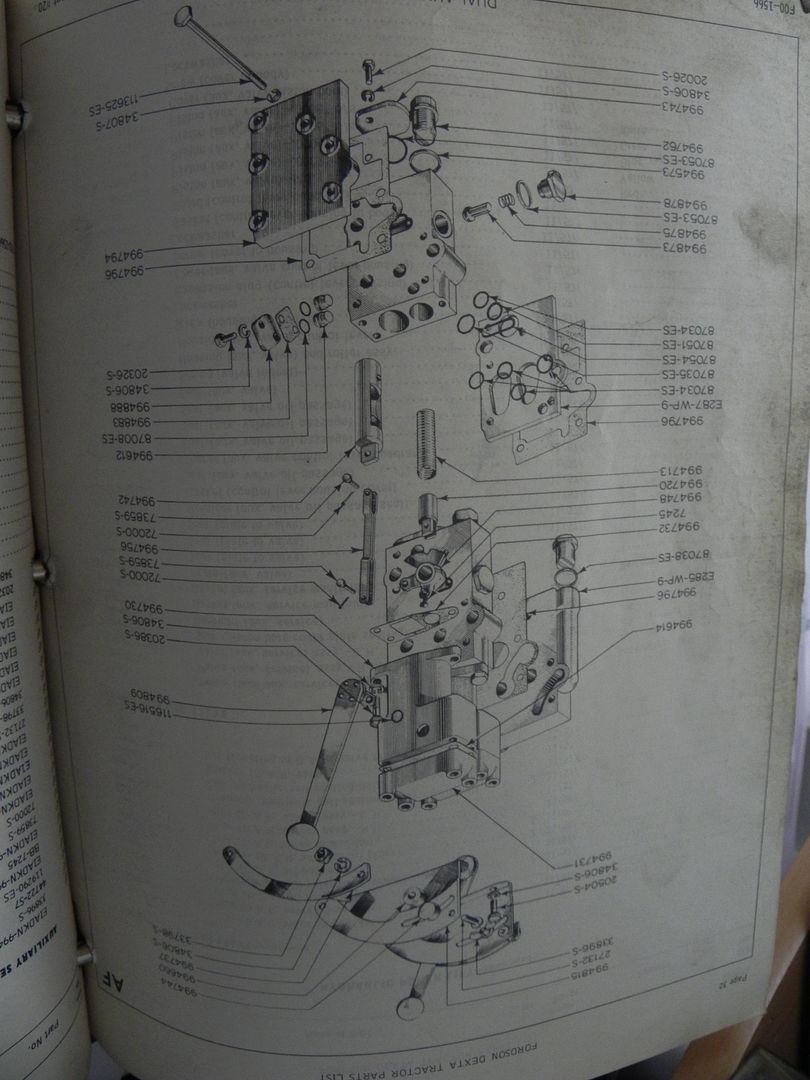

Ford spool valve for Super Major, Dexta and Super Dexta, United Kingdom.

Re: Spool Valves.

Posted: Fri Nov 15, 2013 2:43 pm

by Dandy Dave

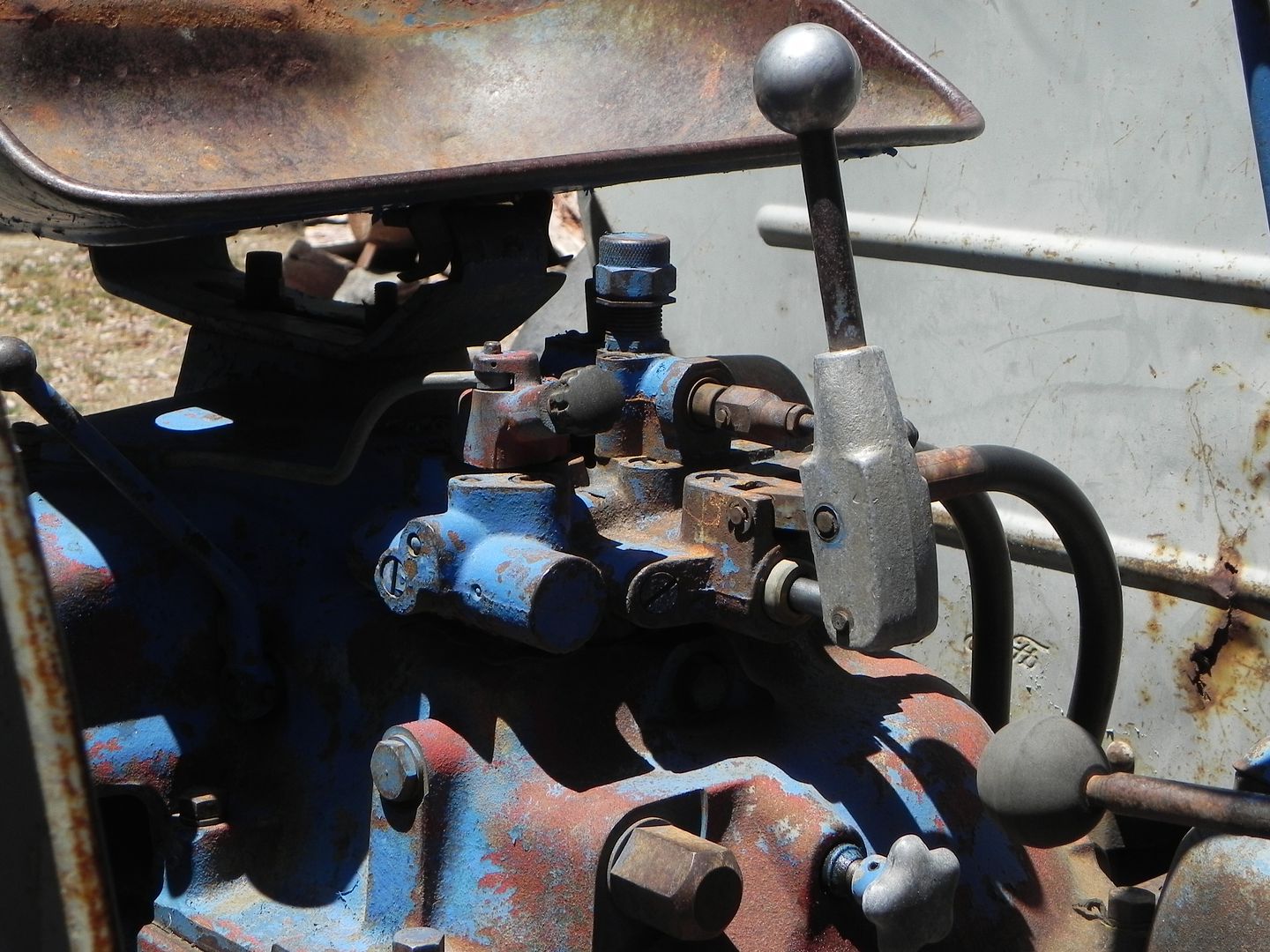

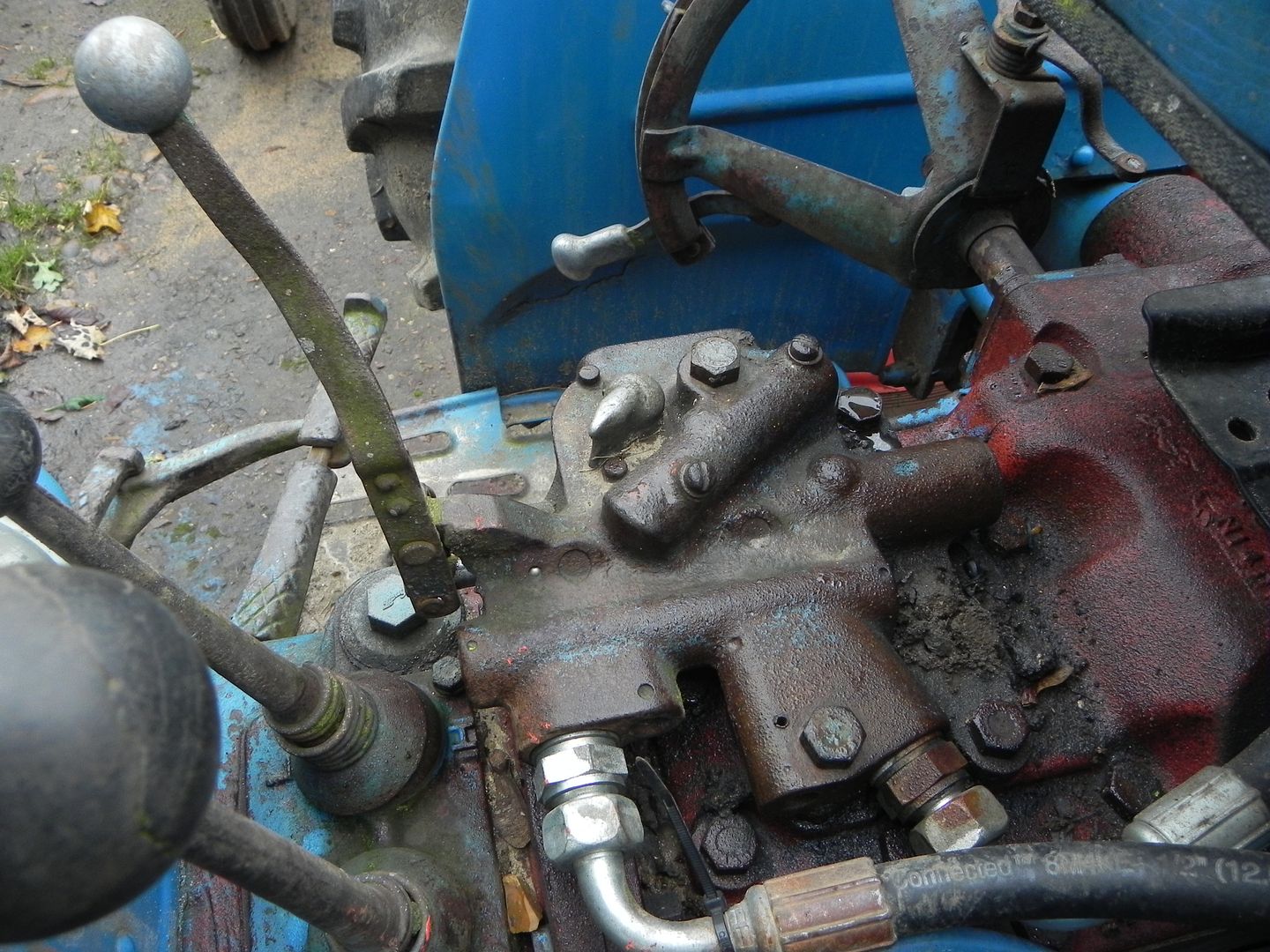

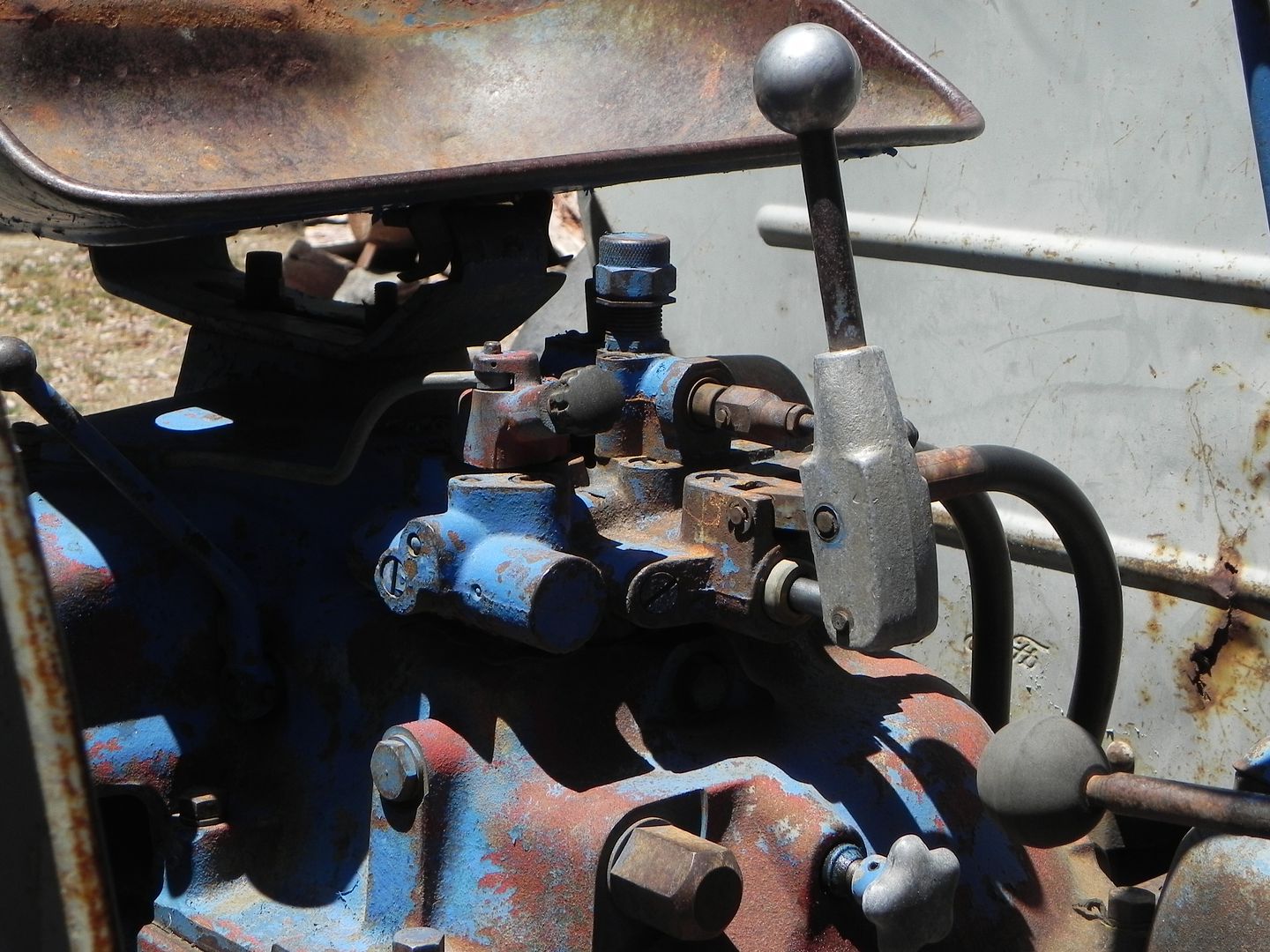

Power Major. United States.

Re: Spool Valves.

Posted: Sun Nov 17, 2013 5:26 pm

by Brian

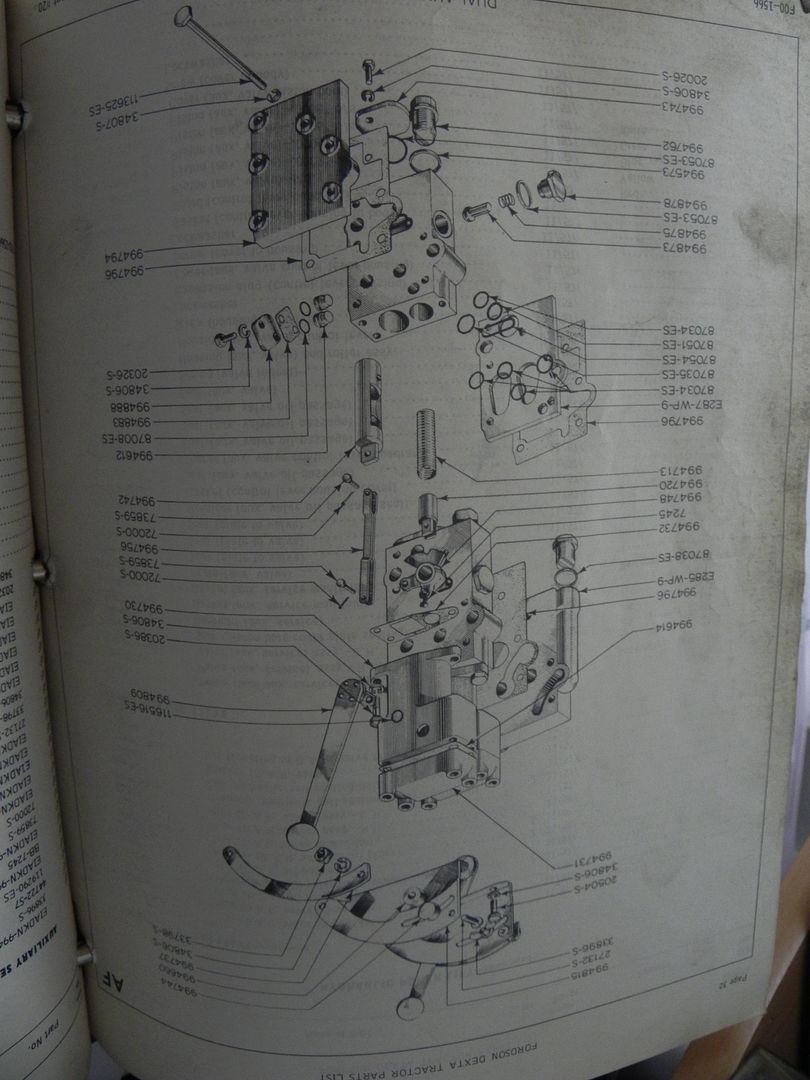

Double acting spool valve for Super Major and Dexta from 1957 to 1964. Mounted on a plate in front of the lift and was piped from the ASC. I think I can remember seeing one but am not sure.

Re: Spool Valves.

Posted: Wed Nov 20, 2013 5:47 pm

by Brian

Spool valves from Australian 5000 tractors.

Re: Spool Valves.

Posted: Fri Mar 14, 2014 4:53 pm

by BearCreek Majors

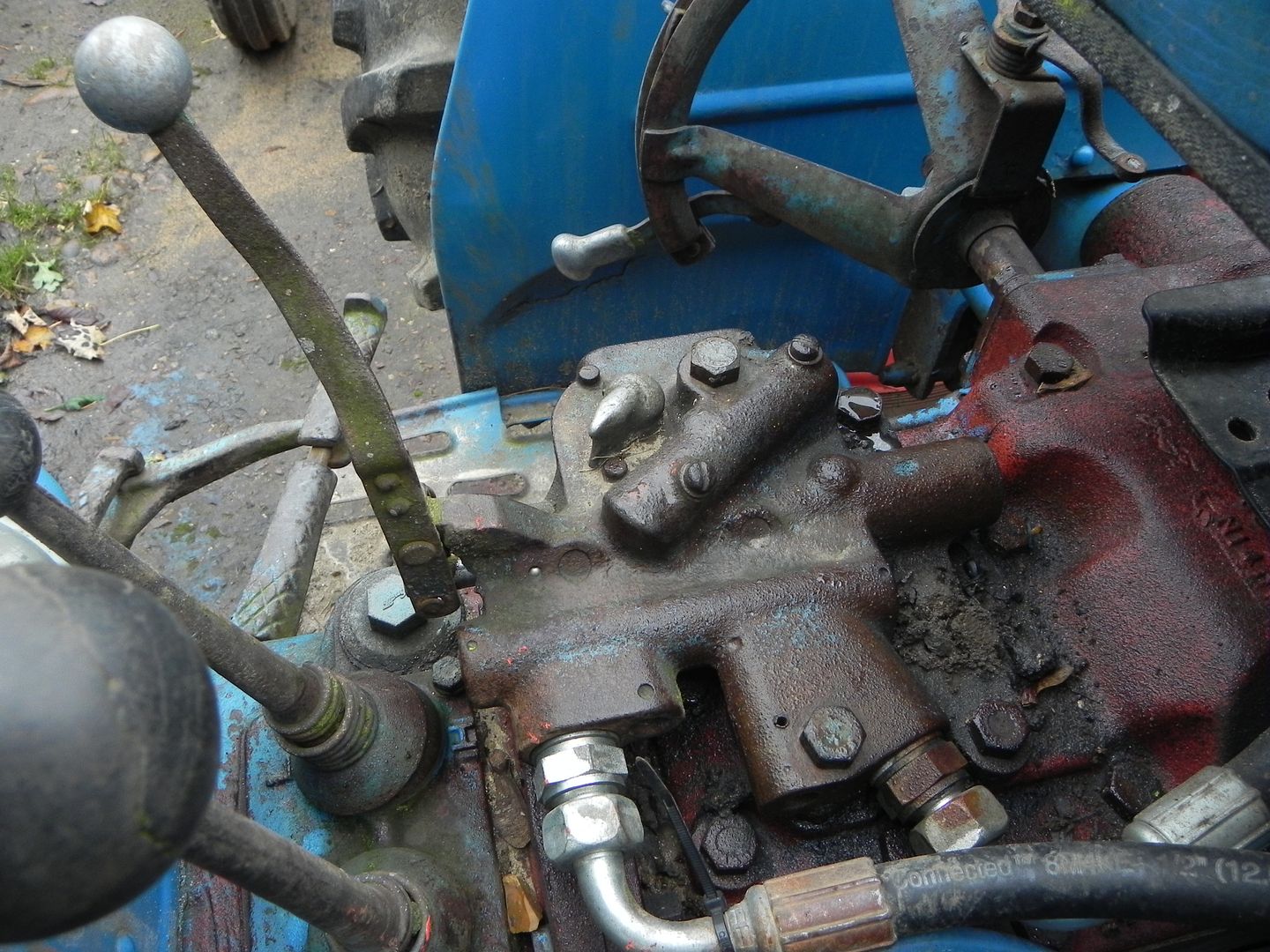

found this one on a Doe.

Re: Spool Valves.

Posted: Wed May 28, 2014 2:47 pm

by HoldTight

In this Fordson pdf file

http://www.fordson.se/5_Hydraulik_Verks ... 47-166.pdf I found the following:

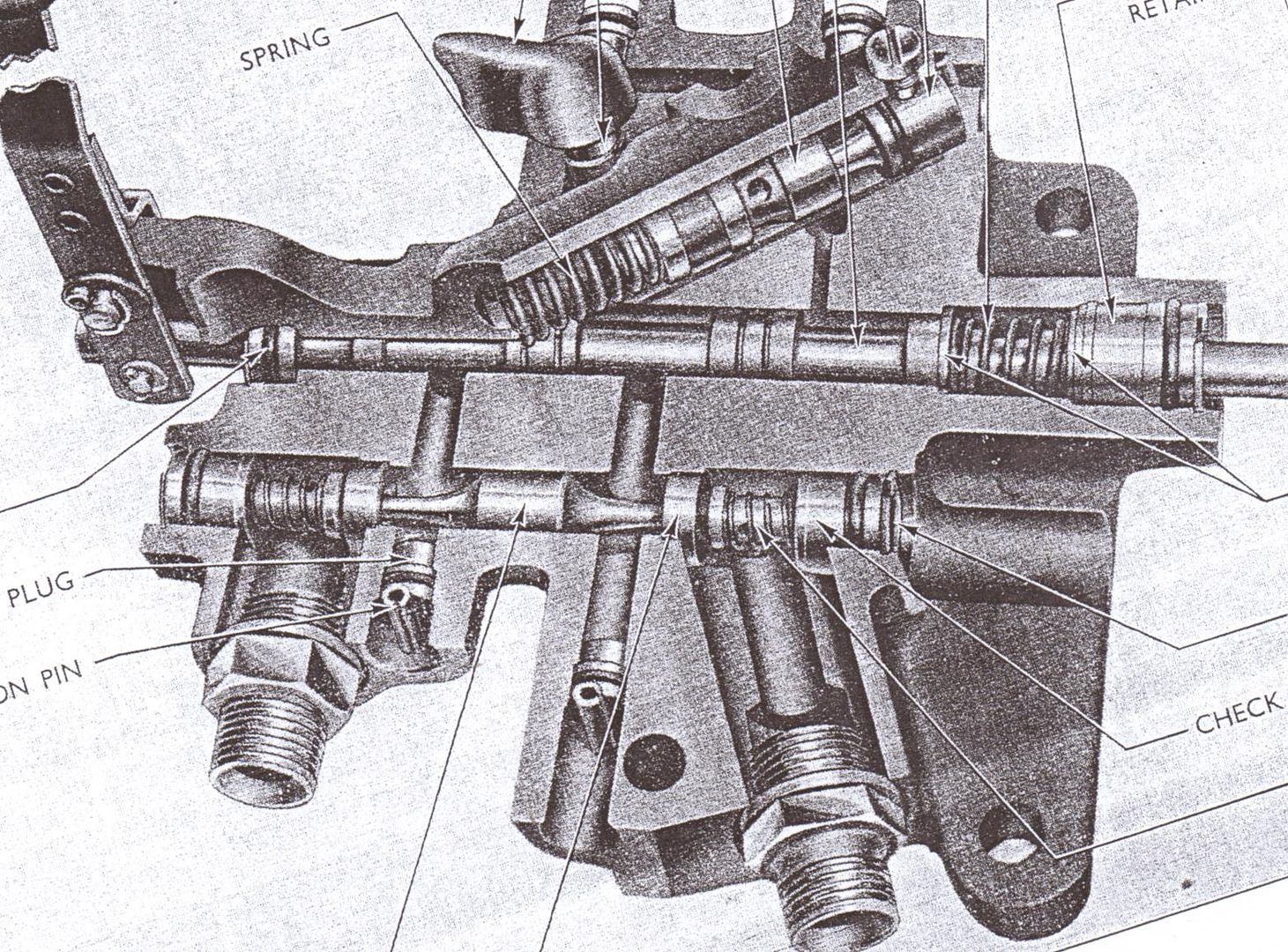

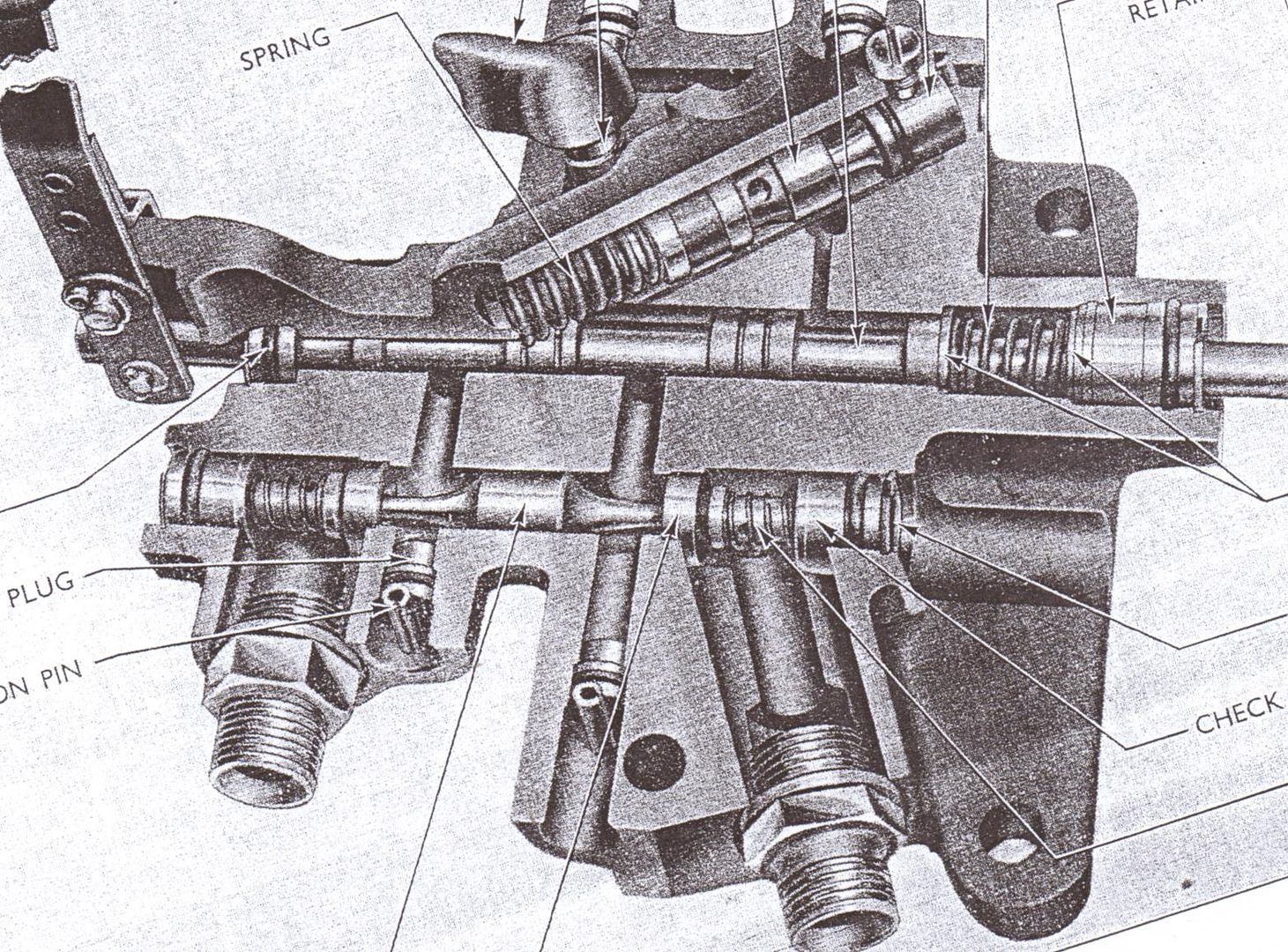

"Valve Control Unit

The valve control unit is located at the front end of the ram cylinder housing and contains a control lever, piston

valve, non-return valve, unloading valve and a jack tapping. Oil is delivered from the pump, through the feed pipes to

the piston valve ; movement of this valve along its bore is controlled by the hand lever, which is returned to the neutral

position by the cam roller and spring, housed in the lever body, as soon as the lever is released.

A jack tapping is provided, adjacent to the piston valve bore end plate, for those applications where external hydraulic

pressure is required.

A second valve unit may be bolted to the front of the existing valve body to provide an additional

hydraulic service."

My aim is to be able to use a 1952 Fordson Major with a hydraulic fence post knocker. The tractor currently has the single hydraulic lever which operates the link arms and when they have raised to the top of their travel then diverts oil to the tipping pipe. This is unsuitable for use with a post knocker.

I would like to know if bolting on a second hydraulic valve unit would give a single acting auxiliary hydraulic service which is

independent to the operation of the three point link arms?

With thanks,

HoldTight.

Re: Spool Valves.

Posted: Wed May 28, 2014 7:19 pm

by chriss

I did try this but could only raise the hammer a short way then the relief valve would come in nothing wrong with the hydraulics, it's just the way they are, that was on

a 55 major

Re: Spool Valves.

Posted: Wed May 28, 2014 7:38 pm

by HoldTight

Just to clarify Chris, you added a second hydraulic valve to give a second service? Would the second service operate independently of the link arms?

Why did the relief valve blow all the time? Lifting the post knocker weight is relatively light work compared with say, tipping a loaded trailer!

HoldTight.

Re: Spool Valves.

Posted: Wed May 28, 2014 8:17 pm

by chriss

That's right I've got one on each of my 55 majors but I think it's the position of the ram and pivot point there next to no leverage I did have a post on here about it a year or so ago might be worth looking at

Re: Spool Valves.

Posted: Mon Jun 23, 2014 5:58 pm

by HoldTight

Can anyone provide information on what parts are needed to add a second hydraulic service to a 1952 new Major.

Thanks,

HoldTight.

Found the answer:

http://www.fordsontractorpages.nl/phpbb ... hp?p=25845

Re: Spool Valves.

Posted: Fri Sep 12, 2014 8:39 am

by 1962 model

I have been considering this issue myself and I have decided to permemantly block the supply tube

from the tapping point at the right hand rear of the seat and the TPL lift handle, ( need to remove the valve body to get it out ) I see no reason why I shouldn't take a supply from this taping point and return the flow via an external hose to the plug immediately behind the lift handle.

The Fordsons use a hydraulic pressure between 2000 and 2200 PSI and these pressures should not be exceeded without risking sheering the hydraulic pump drive gear key or worse.

By having a external path for the main oil supply to the standard Fordson hydraulics, gives the oppertunity to fit a modern remote spool valve in this line, ( from your local supplier ), but this must be the one with the adjustable pressure relief valve to avoid exceeding the Fordsons maximum 2200 PSI.

In doing this it will still allow for the normal TPL hydraulics and the additioanal double acting supply too.

If the the TPL hydraulics are not being used as in the situation of some fork lifts which are braced to stop them lifting, then a single acting supply should also be possible at the same time through the tapping hole on the left side.

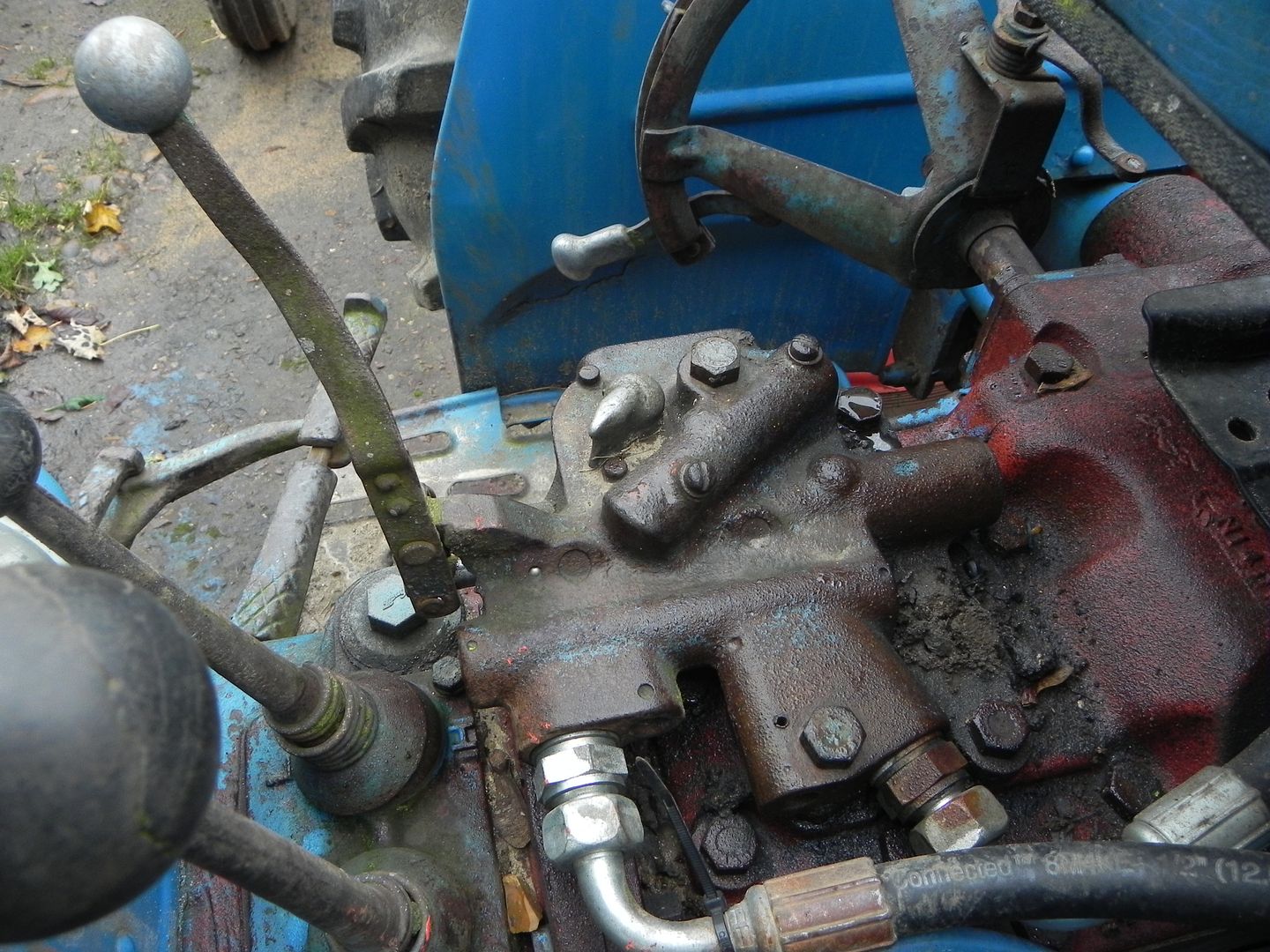

I have both a single acting and double acting suppy on my Power Major, but I have the Australian accessory spool block as shown in the picture above, the method I have outlined is for one of my other tractors.

Although not essential, the best oil pump to use is the higher volume Super Major one, in the past these could be ordered for use in the 1954 to 1960 models, and a special adapter elbow was available from Ford to fit the verticle delivery tube that these models used.

If you had access to a Super Major pump, a right angle adapter elbow could be made.

Agriline were supplying the old type 1954 - 60 pump, few people are aware of the upgrade by Ford all those years ago!

I have the upgraded pump in my Power Major, and I was using it to good effect this morning, it gives an increased volume of oil for a faster hydraulic lift, it achives this by a smaller driven gear the resultant changing of the pump angle, the pump gears themselves are likely quite similar.

Mike

Re: Spool Valves.

Posted: Thu Apr 19, 2018 7:11 am

by guduell

If i find and mount some spool valve for the super major will thisoutlet be independent of the position of the main lever and of the draft/position control lever?

Ie will the main lever control the the point arms and the outlet(s) in front of the saddle control external connections?

My 58 major has the extra aux lever and by this i get two independent funtions, one for the the point arms (and also an d independent external) rear and one for the front loader.