First Failure?

Re: First Failure?

That would be true as temperature and pressure are closely linked. When you increase one you increase the other untill the weakest link in the system fails. With a no pressure rad cap which in truth probably allows a couple of Lb of force. You could apply a temp change that would cause a 50 psi increase in pressure but once the caps limit is reached the pressure is dumped so the extra pressure is never generated. Also the 181℉ is still within the designed running temp peramiters of the engine.

A good analogy is if you fill a syringe with 25ml of water put you finger over the end and compress down to 10ml and the water squirts out passed your finger. Now you may have the strength to compress it down to 2ml but your finger cannot hold the pressure back so you'll never get down there.

A good analogy is if you fill a syringe with 25ml of water put you finger over the end and compress down to 10ml and the water squirts out passed your finger. Now you may have the strength to compress it down to 2ml but your finger cannot hold the pressure back so you'll never get down there.

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: First Failure?

The temp and pressure relationships you note are for gasses. Liquids are almost incompressible hence use in hydraulics and why bleeding gas out of liquid pressure systems is so important.

One aspect of boiling water often missed is that the amount of extra heat you have to pump into to (nominal) 100 degree C water to convert it to steam is huge (Latent heat of evaporation, why steam engines are so powerful) and this is the thermal reserve between hot and boiling which efficient radiator cooling systems capitalise on.

At whatever the days atmospheric pressure is there will be a temperature at which the coolant will start to boil somewhere in the block if the input of heat exceeds the ability of the air through the rad to shed it, with a non pressurised cap the volume of water displaced by generation of steam will just run out of the overflow, the coolant system pressure will not rise but as less liquid coolant runs through the rad and block cooling effect is increasingly limited and as coolant is lost the risk of block or head damage increases rapidly. The operation of the thermostat needs to be below boiling point at the altitude the engine is used plus a margin of safety, whatever other damage occurs the liner O rings are not being unduly pressurised.

With a pressurised cap, the system pressure can rise above atmospheric and will thereby increase the effective boiling point (so tending to restrict boiling until more energy is put in from the block, all the while the cooling effect of the rad is shedding heat and this will be more efficiently shed than in a no pressure system and the engine can deliver more power. The choice of thermostat in terms of temperature of opening, hysteresis (rate and extent of opening & closing) and flow volume will determine performance but choices will be limited so the Major engine also has the option of some amount of fan control in direction blade is fitted and ability to fit one or two blades. Fitting a warmer thermostat can be fine tuned using the fan options if it doesn't work out of the box as hoped,

None of these factors alters the real risk that in an old Major engine the liner seals may have turned to goo and any significant pressure in the coolant system may end up with some of it getting past into the oil side of the engine.

Pretty sure you know all this 58vintage but for those who look at this forum in the future it may clarify things and stop an engine being spoiled and especially the fan options seem to be rarely discussed when talking cooling systems.

One aspect of boiling water often missed is that the amount of extra heat you have to pump into to (nominal) 100 degree C water to convert it to steam is huge (Latent heat of evaporation, why steam engines are so powerful) and this is the thermal reserve between hot and boiling which efficient radiator cooling systems capitalise on.

At whatever the days atmospheric pressure is there will be a temperature at which the coolant will start to boil somewhere in the block if the input of heat exceeds the ability of the air through the rad to shed it, with a non pressurised cap the volume of water displaced by generation of steam will just run out of the overflow, the coolant system pressure will not rise but as less liquid coolant runs through the rad and block cooling effect is increasingly limited and as coolant is lost the risk of block or head damage increases rapidly. The operation of the thermostat needs to be below boiling point at the altitude the engine is used plus a margin of safety, whatever other damage occurs the liner O rings are not being unduly pressurised.

With a pressurised cap, the system pressure can rise above atmospheric and will thereby increase the effective boiling point (so tending to restrict boiling until more energy is put in from the block, all the while the cooling effect of the rad is shedding heat and this will be more efficiently shed than in a no pressure system and the engine can deliver more power. The choice of thermostat in terms of temperature of opening, hysteresis (rate and extent of opening & closing) and flow volume will determine performance but choices will be limited so the Major engine also has the option of some amount of fan control in direction blade is fitted and ability to fit one or two blades. Fitting a warmer thermostat can be fine tuned using the fan options if it doesn't work out of the box as hoped,

None of these factors alters the real risk that in an old Major engine the liner seals may have turned to goo and any significant pressure in the coolant system may end up with some of it getting past into the oil side of the engine.

Pretty sure you know all this 58vintage but for those who look at this forum in the future it may clarify things and stop an engine being spoiled and especially the fan options seem to be rarely discussed when talking cooling systems.

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: First Failure?

I hope you don't mind me enlarging on your informative info, Rick, as coolant temperature control is very much a serious subject here in Oz -- especially with older diesel engines.

Firstly, the heat generated by ignition in our diesel engines on the piston crowns when the tractor is at operating temp, and in heavy[ish] work, is in the region of 350 to 400 degrees C. Whilst some of this is dissipated by oil flow, the dominant factor is down to the water circulating through a heat exchanger -- the radiator -- aided by the flow of air through it and the circulating water movement.

For some reason many owners place great store on the operating temperature of the thermostat believing that the higher the degree it opens, the better control of overheating it has. This is a fallacy! Its main purpose is to permit the temperature around the cylinders to reach operating efficiency sooner by restricting water flow away from them ; plus cyl. heat loss when operating in cold weather. In such cold weather I would suggest that a 181F [82C] thermostat is much too high a temp. -- even though here in Oz I use a 181F and we have ground frost some winter mornings.

Bearing in mind that un-pressurised coolant will boil at 212F [100C], having a thermostat that is fully opened at 181F does not give an engine very much leeway before it overheats. To my mind having a coolant radiator pressure cap set at 4 PSI, which raises the boiling point to 222F [106C], gives a much safer margin -- and better allowance for water channel restrictions caused by rust and calcium deposits. It's also what Ford recommends.

One last point. Even with a water temperature gauge, unless water is flowing over the bulb of the sensor the correct temperature is not being recorded. The system could be boiling without you realising it.

Pavel

Firstly, the heat generated by ignition in our diesel engines on the piston crowns when the tractor is at operating temp, and in heavy[ish] work, is in the region of 350 to 400 degrees C. Whilst some of this is dissipated by oil flow, the dominant factor is down to the water circulating through a heat exchanger -- the radiator -- aided by the flow of air through it and the circulating water movement.

For some reason many owners place great store on the operating temperature of the thermostat believing that the higher the degree it opens, the better control of overheating it has. This is a fallacy! Its main purpose is to permit the temperature around the cylinders to reach operating efficiency sooner by restricting water flow away from them ; plus cyl. heat loss when operating in cold weather. In such cold weather I would suggest that a 181F [82C] thermostat is much too high a temp. -- even though here in Oz I use a 181F and we have ground frost some winter mornings.

Bearing in mind that un-pressurised coolant will boil at 212F [100C], having a thermostat that is fully opened at 181F does not give an engine very much leeway before it overheats. To my mind having a coolant radiator pressure cap set at 4 PSI, which raises the boiling point to 222F [106C], gives a much safer margin -- and better allowance for water channel restrictions caused by rust and calcium deposits. It's also what Ford recommends.

One last point. Even with a water temperature gauge, unless water is flowing over the bulb of the sensor the correct temperature is not being recorded. The system could be boiling without you realising it.

Pavel

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: First Failure?

Absolutely Pavel, the joy of these forum topics is that they record a wide range of experience and practice from people who collectively have goodness knows how many man-decades of accumulated knowledge between them, adding to a jigsaw that will help others into the future who are perhaps first time tractor owners, things like cooling are not just Ford/Fordson related even if the fine detail of model specific nature is. Not all makes of tractor appear to have the super resource we have available here thanks to the 'Founding Fathers' and admins of the site.

I find Brians contributions particularly fascinating because short of having someone from F/F design or Service join in, this is the nearest anyone will ever get to first hand practical factory knowledge (complete with the application related dimension which even lifetime factory guys might not pick up) throughout a big chunk of tractor history - even if his categorical pronouncements on grille colour are sometimes queried !

Your knowledge of the burning hot, the Canadian/NA or Scandanavian guys experience on near Arctic conditions plus everyone inbetween all add to the pot.

Its unusual for a daqy to go by without reading something to either file for future use or simply think 'I didn't know that'

edit typo and I'm not buttering Brian up just cos I expect to see him & Ann Sunday

I find Brians contributions particularly fascinating because short of having someone from F/F design or Service join in, this is the nearest anyone will ever get to first hand practical factory knowledge (complete with the application related dimension which even lifetime factory guys might not pick up) throughout a big chunk of tractor history - even if his categorical pronouncements on grille colour are sometimes queried !

Your knowledge of the burning hot, the Canadian/NA or Scandanavian guys experience on near Arctic conditions plus everyone inbetween all add to the pot.

Its unusual for a daqy to go by without reading something to either file for future use or simply think 'I didn't know that'

edit typo and I'm not buttering Brian up just cos I expect to see him & Ann Sunday

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: First Failure?

Thanks for that Oehrick. I tried to simplify my A level physics knowledge it looks like not overly successfully, whilst trying to remember it to. lol.

Pavel I would have to respectively disagree with a 181℉ being to hot. Pure water boils at 100℃ unless the tractor is located at a good altitude. The main reasons we add antifreeze to that water is to lower the freezing temp and increase the boiling point. Also unless somewhere very warm or in really hard work you would find in something as overcooled as our majors a 181℉ will maintain a lower temp than this as the thermostat has started to open at a lower temp. Mine for example maintains a temp of about 175℉.

I should say that although we refer to our systems as no pressure this is inaccurate in the scientific sense. I would have thought you were correct and like I said all our systems will have a couple of PSI in them. If the pump couldn't generate any pressure at all it would not be able to pump coolant to the top of the engine. They are no pressure systems in relation to modern ones which run at up to 1.6 bar or 23.2psi in common systems.

Of course the thermostat to will have no control on over heating as once it's fully open its fully open

It just enables you to reach running temp quicker and easier.

Pavel I would have to respectively disagree with a 181℉ being to hot. Pure water boils at 100℃ unless the tractor is located at a good altitude. The main reasons we add antifreeze to that water is to lower the freezing temp and increase the boiling point. Also unless somewhere very warm or in really hard work you would find in something as overcooled as our majors a 181℉ will maintain a lower temp than this as the thermostat has started to open at a lower temp. Mine for example maintains a temp of about 175℉.

I should say that although we refer to our systems as no pressure this is inaccurate in the scientific sense. I would have thought you were correct and like I said all our systems will have a couple of PSI in them. If the pump couldn't generate any pressure at all it would not be able to pump coolant to the top of the engine. They are no pressure systems in relation to modern ones which run at up to 1.6 bar or 23.2psi in common systems.

Of course the thermostat to will have no control on over heating as once it's fully open its fully open

It just enables you to reach running temp quicker and easier.

Re: First Failure?

Thanks for your diplomatic response to my post, James. I had spent about an hour two finger writing a reply to you comments; went to make a cuppa and came back to find my laptop had shut down and I'd lost the lot. I'll now just confine myself to writing about thermostats and cover anti-freeze later as it's nearly midnight and I'm a bit tired.

Thermostats.

Contrary to popular belief, the temperature designation printed on the container the thermostat comes in is NOT the temperature at which the disc, and therefore its maximum lift, is fully open. It is, in fact, the temp. at which it STARTS to open [plus or minus 2 degrees F]. This is a world wide industry standard. Maximum lift is not reached until a further rise in temperature of 20 degrees F or 10C -- also an industry standard. Engine manufacturers determine the steady state temperature a new engine reaches under light load conditions and designate an appropriate thermostat that obtains half its maximum lift at that running temp. This ensures it can open further under a prolonged heavy work load; or slightly close whilst working lightly or idling.

The recommendation for the early diesel Majors was 160F and for the Super Major 176F. Both of these were for an un-pressurised cooling system -- even though 4 or 7psi rad. caps were suggested for hot climates. Plus, as Richy mentioned, a 4 bladed fan.

What I cannot understand, James, is that you say you have fitted a 181F thermostat, which has a range of 181 to 201F, yet your steady state coolant temp. is 175F which is below that at which the thermostat begins to open. Something doesn't gel.

Pavel

Thermostats.

Contrary to popular belief, the temperature designation printed on the container the thermostat comes in is NOT the temperature at which the disc, and therefore its maximum lift, is fully open. It is, in fact, the temp. at which it STARTS to open [plus or minus 2 degrees F]. This is a world wide industry standard. Maximum lift is not reached until a further rise in temperature of 20 degrees F or 10C -- also an industry standard. Engine manufacturers determine the steady state temperature a new engine reaches under light load conditions and designate an appropriate thermostat that obtains half its maximum lift at that running temp. This ensures it can open further under a prolonged heavy work load; or slightly close whilst working lightly or idling.

The recommendation for the early diesel Majors was 160F and for the Super Major 176F. Both of these were for an un-pressurised cooling system -- even though 4 or 7psi rad. caps were suggested for hot climates. Plus, as Richy mentioned, a 4 bladed fan.

What I cannot understand, James, is that you say you have fitted a 181F thermostat, which has a range of 181 to 201F, yet your steady state coolant temp. is 175F which is below that at which the thermostat begins to open. Something doesn't gel.

Pavel

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: First Failure?

Enjoying this discussion. Just chucking in an observation.

The cooling system on the Major is evidently effective. Once the thermostat is fully open, at whatever temperature, the pump impeller moves the coolant through the rad at a rate that allows an efficient loss of heat to the atmosphere.

Moving on from observation to opinion (!), I think the water pump impeller flow rate/rad core surface area results in an extremely efficient cooling effect. [Note the word ‘extremely’!]

With a lower temp thermostat, I believe the cooling system does what it was designed to do and locks the engine into a lower than desirable coolant temperature operating environment. This is why one often hears owners saying that they need to work their tractors hard to move the temperatures higher - they are fighting against a system that, after start-up, is keeping the water jacket at too low a temperature. I use my Major to run a sawbench. The bench draws very little power from the tractor, and I geared the bench to run at optimal speed at a fast engine tick-over. Yet the temperature gauge moves quickly to a similar needle position to when I am ploughing, and then it sits there.

Not sure how helpful these observations/opinions are!

Best, Adrian.

The cooling system on the Major is evidently effective. Once the thermostat is fully open, at whatever temperature, the pump impeller moves the coolant through the rad at a rate that allows an efficient loss of heat to the atmosphere.

Moving on from observation to opinion (!), I think the water pump impeller flow rate/rad core surface area results in an extremely efficient cooling effect. [Note the word ‘extremely’!]

With a lower temp thermostat, I believe the cooling system does what it was designed to do and locks the engine into a lower than desirable coolant temperature operating environment. This is why one often hears owners saying that they need to work their tractors hard to move the temperatures higher - they are fighting against a system that, after start-up, is keeping the water jacket at too low a temperature. I use my Major to run a sawbench. The bench draws very little power from the tractor, and I geared the bench to run at optimal speed at a fast engine tick-over. Yet the temperature gauge moves quickly to a similar needle position to when I am ploughing, and then it sits there.

Not sure how helpful these observations/opinions are!

Best, Adrian.

Re: First Failure?

G'day Adrian; and thanks for the comments and observation. But you are naughty cutting up all that wood and burning it to keep warm. Haven't you heard about global warming and how burning fossil fuel produces all those nasty CO2 molecules that makes our plants grow? [Written in front of the dying embers of my log fire].

Just a couple of Qs.

Do you mean a lower thermostat temp. than a 181F or lower than the ones Ford recommend?

Is your observation made with anti-freeze in the Fordson? with/without a pressurized rad. cap and/or a 4 blade fan?

Just so we can compare apples with apples.

As mentioned to James; I intend commenting later about the effects of ethylene glycol anti-freeze on coolant temperatures.

Pavel

Just a couple of Qs.

Do you mean a lower thermostat temp. than a 181F or lower than the ones Ford recommend?

Is your observation made with anti-freeze in the Fordson? with/without a pressurized rad. cap and/or a 4 blade fan?

Just so we can compare apples with apples.

As mentioned to James; I intend commenting later about the effects of ethylene glycol anti-freeze on coolant temperatures.

Pavel

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: First Failure?

Hi Pavel

My naughtiness knows no bounds - I was even puffing out CO2 myself when cutting the wood.

But to balance things out, my Major is solar powered [diesel = stored sunlight].

Re my thermostat, I asked my parts supplier (Silver Fox, if I remember rightly) for a hotter thermostat than the stock item. I don’t know what temp it is set to open at, but on trial it took the operating temperature up the scale into the middle of the third sector of the Super temperature gauge. Given the crude calibration of the gauge I reckon the needle position indicates a water temp of approx 190F.

I’m unaware of what the Ford recommendation is regarding stat temp settings, and to be frank, I wasn’t clear on how stats are rated. The Dieselsite 203F stat info I posted seems to imply that 203 is the temperature at which it is fully open.

Yes, the system is filled with an antifreeze mixture.

No pressurised cap and a two blade fan.

Re the pressurised cap, can you explain how this would work? Would it close off the overflow pipe in the neck of the filler aperture?

Best, Adrian.

My naughtiness knows no bounds - I was even puffing out CO2 myself when cutting the wood.

But to balance things out, my Major is solar powered [diesel = stored sunlight].

Re my thermostat, I asked my parts supplier (Silver Fox, if I remember rightly) for a hotter thermostat than the stock item. I don’t know what temp it is set to open at, but on trial it took the operating temperature up the scale into the middle of the third sector of the Super temperature gauge. Given the crude calibration of the gauge I reckon the needle position indicates a water temp of approx 190F.

I’m unaware of what the Ford recommendation is regarding stat temp settings, and to be frank, I wasn’t clear on how stats are rated. The Dieselsite 203F stat info I posted seems to imply that 203 is the temperature at which it is fully open.

Yes, the system is filled with an antifreeze mixture.

No pressurised cap and a two blade fan.

Re the pressurised cap, can you explain how this would work? Would it close off the overflow pipe in the neck of the filler aperture?

Best, Adrian.

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: First Failure?

Hi all

James - my physics is at the same sort of level other than I've specialised in steam technology over the years so the thermal stuff regarding water is a wee bit more recently used - Given the chances of us all sitting round a pub table chewing over this sort of thing with a beer, comparing what we think we understand with others understanding, is about nil so this is a very enjoyable and educational aspect of the forum.

Adrian, the pressurised cap I got had a rubber disc of perhaps 1 - 1.5 mm thickness under the sprung metal plate, sealing the neck under the overflow pipe level, stronger spring so a bit like a Mamod safety valve, when enough pressure builds it lifts and vents. David at Mid Norfolk Tractors is midway between where I and the Major live and was very concerned that I fitted it and gave me a NP cap and strict instructions to go back, release pressure and swap them over (He had recently bought my Nuffy M4 so I called in on the way home to let him know that the first 'after rad fixing' run with the Major had gone well. (BTW you are probably near the Famous Fox but although David only advertises Nuffy parts he is very knowledgeable about other makes and can get or holds parts - I should have asked him first!)

Pavel, Looking forward to learning more about the effects of anti freeze, while knowing a bit about water and its foibles on boiling, condensing or freezing, I've no idea what antifreeze does specific heat capacity wise, especially at the upper end of coolant temperatures.

My Major also runs on liquid sunshine, we don't have a woodburner due to a high fire risk roof but my other 'tractor' runs on solidified sunshine (or black diamonds) while I no longer have the website running, much of it was captured by the Wayback Machine, so if you fancy a laugh have a look at

http://web.archive.org/web/201012131536 ... /index.htm

Scroll down and click on 'The Dodman' link

James - my physics is at the same sort of level other than I've specialised in steam technology over the years so the thermal stuff regarding water is a wee bit more recently used - Given the chances of us all sitting round a pub table chewing over this sort of thing with a beer, comparing what we think we understand with others understanding, is about nil so this is a very enjoyable and educational aspect of the forum.

Adrian, the pressurised cap I got had a rubber disc of perhaps 1 - 1.5 mm thickness under the sprung metal plate, sealing the neck under the overflow pipe level, stronger spring so a bit like a Mamod safety valve, when enough pressure builds it lifts and vents. David at Mid Norfolk Tractors is midway between where I and the Major live and was very concerned that I fitted it and gave me a NP cap and strict instructions to go back, release pressure and swap them over (He had recently bought my Nuffy M4 so I called in on the way home to let him know that the first 'after rad fixing' run with the Major had gone well. (BTW you are probably near the Famous Fox but although David only advertises Nuffy parts he is very knowledgeable about other makes and can get or holds parts - I should have asked him first!)

Pavel, Looking forward to learning more about the effects of anti freeze, while knowing a bit about water and its foibles on boiling, condensing or freezing, I've no idea what antifreeze does specific heat capacity wise, especially at the upper end of coolant temperatures.

My Major also runs on liquid sunshine, we don't have a woodburner due to a high fire risk roof but my other 'tractor' runs on solidified sunshine (or black diamonds) while I no longer have the website running, much of it was captured by the Wayback Machine, so if you fancy a laugh have a look at

http://web.archive.org/web/201012131536 ... /index.htm

Scroll down and click on 'The Dodman' link

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: First Failure?

Fascinating stuff, Rick; I've always been awestruck with those huge machines which radiate enormous power. Sadly it reminded me of the large destructive bush fire we had over the summer which destroyed a whole town, including a renowned working steam museum.

http://www.watoday.com.au/wa-news/wa-fi ... m1txv.html

Anyway; back to the subject -- ethylene glycol anti-freeze.

It appears to be a fairly well known fact, if not completely understood why, that the inclusion of ethylene glycol type anti-freeze raises the boiling point of plain water. For the record, a 25% mix raises the boiling point to 103 C, with a 50% solution upping it to 107 C -- akin to pressurizing the system by using a rad. cap rated at 4psi or 7psi.

All well and good; but like most things in life there is a trade off. Because of its specific gravity, the inclusion of E.G. raises its viscosity. This means that its ability to dissipate [shed] heat is lower. In order to maintain the same heat disposal Shark as plain water the flow rate for a 25% solution would need to be upped by approx. 9% -- and that of a 50% mix to 14%. Obviously not a problem during cold winter months; but during warmer weather, whilst performing a prolonged heavy work load, the potential to overheat is much greater -- especially with regards to a cooling system that has seen better days.

Alternatively one could use the more expensive propylene glycol type anti-freeze -- but this is not recommended for use in older type high compression diesel engines because P.G. does nothing to combat the destructive effects of cavitation of the cylinder walls -- whereas E.G. does.

Adrian, just a word about rad. caps.

Majors were generally supplied with un-pressured caps with a spring loaded valve that vented any built up pressure to the atmosphere. Pressure caps, 4, 7psi and above etc, had the cap spring pressure increased to allow a pre-set rise before, again, venting to the outside atmosphere. The modern version is termed a 'recovery' pressure cap. These have an additional rubber seal around sealing plate which only opens enough to allow excess coolant to escape via the overflow pipe which is, in turn, connected to a bottle/metal container. This build-up of coolant is then sucked back into the radiator as the cooling coolant contracts thus maintaining the radiator level.

I have converted my classic Triumph car to this system and it works well. If I could get the correct rad. cap for the Major I would do the same for it.

Pavel

http://www.watoday.com.au/wa-news/wa-fi ... m1txv.html

Anyway; back to the subject -- ethylene glycol anti-freeze.

It appears to be a fairly well known fact, if not completely understood why, that the inclusion of ethylene glycol type anti-freeze raises the boiling point of plain water. For the record, a 25% mix raises the boiling point to 103 C, with a 50% solution upping it to 107 C -- akin to pressurizing the system by using a rad. cap rated at 4psi or 7psi.

All well and good; but like most things in life there is a trade off. Because of its specific gravity, the inclusion of E.G. raises its viscosity. This means that its ability to dissipate [shed] heat is lower. In order to maintain the same heat disposal Shark as plain water the flow rate for a 25% solution would need to be upped by approx. 9% -- and that of a 50% mix to 14%. Obviously not a problem during cold winter months; but during warmer weather, whilst performing a prolonged heavy work load, the potential to overheat is much greater -- especially with regards to a cooling system that has seen better days.

Alternatively one could use the more expensive propylene glycol type anti-freeze -- but this is not recommended for use in older type high compression diesel engines because P.G. does nothing to combat the destructive effects of cavitation of the cylinder walls -- whereas E.G. does.

Adrian, just a word about rad. caps.

Majors were generally supplied with un-pressured caps with a spring loaded valve that vented any built up pressure to the atmosphere. Pressure caps, 4, 7psi and above etc, had the cap spring pressure increased to allow a pre-set rise before, again, venting to the outside atmosphere. The modern version is termed a 'recovery' pressure cap. These have an additional rubber seal around sealing plate which only opens enough to allow excess coolant to escape via the overflow pipe which is, in turn, connected to a bottle/metal container. This build-up of coolant is then sucked back into the radiator as the cooling coolant contracts thus maintaining the radiator level.

I have converted my classic Triumph car to this system and it works well. If I could get the correct rad. cap for the Major I would do the same for it.

Pavel

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: First Failure?

Hello Pavel and Rick

Most interesting, Pavel. Thanks for the info. The EG produces mostly beneficial effects, it seems.

Re the pressurised cap and associated overflow reservoir, I will look into this. Sounds like a good way to go.

Re flow rates, I get the impression that the Ford engineers got this about right. Too slow a flow rate would cause a heat build-up in the block, but too fast a flow rate would mean that the coolant was passing through the rad without being properly cooled.

Given the efficiency of the cooling system, assuming it is operating as designed, as it would be after an engine rebuild, as in James' case, I still believe, judging from experience of my own Majors, and having observed other Majors, that the factory-fitted stat opens at too low a temperature, leading to the efficient cooling system holding the water jacket at too low a temperature until the tractor encounters hard work. With a higher temp stat, the engine gets up to temperature before the cooling system cuts in, by which time the cooling system then maintains the higher water jacket temp. This is what I have experienced.

It's a pleasure to see a clear smoke stack shortly after start-up.

Best, Adrian.

ps This is another quote from the DieselSite 203F website.

For an unsolicited response from an engineer who wrote:

"You should want your engine's oil & water temperatures warmer to:

1) reduce piston/ring sliding friction,

2) to complete combustion before the crankshaft has rotated so many degrees which translates into more "area under the curve" of piston pressure pushing the connecting rod down to rotate the crankshaft, and

3) to better purge volatile oil-borne combustion byproducts from its oil supply.

Just as injector nozzle pressures over 30,000 psi have enabled diesel designers to generate higher torque from identical total fuel flows of better atomized fuel presenting more surface area to oxygen which induces earlier combustion completion, so too do higher combustion chamber temperatures also cause slightly earlier combustion completion during the power stroke. Earlier combustion completion results in higher gas pressures earlier in the power stroke which are converted into higher average crankshaft rotating pressure. Gas pressure converted earlier into crankshaft rotating work is not later available as waste heat at the bottom of the power stroke. That contrasts with later combustion completion which fails to convert as much gas pressure into crankshaft rotating energy so more gas energy is still available at the bottom of the stroke as waste heat. That complex relationship is why earlier combustion completion, whether caused by better fuel atomization or by higher combustion chamber temperatures, lowers exhaust gas temperatures while simultaneously increasing crankshaft power output. "

Most interesting, Pavel. Thanks for the info. The EG produces mostly beneficial effects, it seems.

Re the pressurised cap and associated overflow reservoir, I will look into this. Sounds like a good way to go.

Re flow rates, I get the impression that the Ford engineers got this about right. Too slow a flow rate would cause a heat build-up in the block, but too fast a flow rate would mean that the coolant was passing through the rad without being properly cooled.

Given the efficiency of the cooling system, assuming it is operating as designed, as it would be after an engine rebuild, as in James' case, I still believe, judging from experience of my own Majors, and having observed other Majors, that the factory-fitted stat opens at too low a temperature, leading to the efficient cooling system holding the water jacket at too low a temperature until the tractor encounters hard work. With a higher temp stat, the engine gets up to temperature before the cooling system cuts in, by which time the cooling system then maintains the higher water jacket temp. This is what I have experienced.

It's a pleasure to see a clear smoke stack shortly after start-up.

Best, Adrian.

ps This is another quote from the DieselSite 203F website.

For an unsolicited response from an engineer who wrote:

"You should want your engine's oil & water temperatures warmer to:

1) reduce piston/ring sliding friction,

2) to complete combustion before the crankshaft has rotated so many degrees which translates into more "area under the curve" of piston pressure pushing the connecting rod down to rotate the crankshaft, and

3) to better purge volatile oil-borne combustion byproducts from its oil supply.

Just as injector nozzle pressures over 30,000 psi have enabled diesel designers to generate higher torque from identical total fuel flows of better atomized fuel presenting more surface area to oxygen which induces earlier combustion completion, so too do higher combustion chamber temperatures also cause slightly earlier combustion completion during the power stroke. Earlier combustion completion results in higher gas pressures earlier in the power stroke which are converted into higher average crankshaft rotating pressure. Gas pressure converted earlier into crankshaft rotating work is not later available as waste heat at the bottom of the power stroke. That contrasts with later combustion completion which fails to convert as much gas pressure into crankshaft rotating energy so more gas energy is still available at the bottom of the stroke as waste heat. That complex relationship is why earlier combustion completion, whether caused by better fuel atomization or by higher combustion chamber temperatures, lowers exhaust gas temperatures while simultaneously increasing crankshaft power output. "

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: First Failure?

If you mean the one being half rolled by Major to get the propshaft and handbrake cable out probably not as that is my 'organ donor'peter2 wrote:Hi Rick,

is that the same Volvo as in the pics last year?

Peter

My 'old reliable' has developed a serious compression failure problem so I bought another one cheap as a runabout so I could do repairs at leisure, unfortunately it has a broken speedometer and dead back springs, the organ donor has just supplied the springs but even with the kind assistance of Brians extensive network of contacts, haven't found the trail of rocking horse droppings which might lead to a working instrument panel or speedo.

(if anyone UK has a 1991/92 Volvo 940 non tubo with Yazaki instrument cluster they are breaking I might want to force money into your hand

Rick

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: First Failure?

Oh Adrian, I had just finished reading Pavels nicely explained anti freeze info and thinking that it was gently filtering into what remains of a memory, then read yours  bringing in another unexpected aspect to the engine temperature equation, if I hadn't already been, I'd have had to go and have a lay down to recover !!

bringing in another unexpected aspect to the engine temperature equation, if I hadn't already been, I'd have had to go and have a lay down to recover !!

I understand what you are saying on the slow heat up but isn't there a bypass to the stat or am I thinking of the S1 Landy stat which has holes to allow an amount of bleedage through it ?? I think part of the problem may be that there must be an element of 'any colour as long as its black' in manufacture so the production has to account for a range of environments and a variety of loads within a standard product, how much regional distributors might have improved the fit for their local conditions I don't know, but with all the Fordson tractors range, 'vanilla' pattern probably had to look at if not worst case scenario, at least best fit for most circumstances and while wearing out may clearly be a more rapid option from what you quoted, more engines would have cooked spectacularly if a higher temperature stat operating temperature had been chosen and cooked engines don't win customers.........

50's technology didn't have the same sort of intelligent stat waxes we have now, just open, close, whoops (did Joe Lucas make them ?)

(did Joe Lucas make them ?)

Hey just thinking about it they actually proved your point, otherwise, why didn't diesel majors have rad blinds like the TVO jobs, oviously they weren't bothered about a quick warm up for the diesels = the case for the prosecution looks as though it probably stands yer lordship

I understand what you are saying on the slow heat up but isn't there a bypass to the stat or am I thinking of the S1 Landy stat which has holes to allow an amount of bleedage through it ?? I think part of the problem may be that there must be an element of 'any colour as long as its black' in manufacture so the production has to account for a range of environments and a variety of loads within a standard product, how much regional distributors might have improved the fit for their local conditions I don't know, but with all the Fordson tractors range, 'vanilla' pattern probably had to look at if not worst case scenario, at least best fit for most circumstances and while wearing out may clearly be a more rapid option from what you quoted, more engines would have cooked spectacularly if a higher temperature stat operating temperature had been chosen and cooked engines don't win customers.........

50's technology didn't have the same sort of intelligent stat waxes we have now, just open, close, whoops

Hey just thinking about it they actually proved your point, otherwise, why didn't diesel majors have rad blinds like the TVO jobs, oviously they weren't bothered about a quick warm up for the diesels = the case for the prosecution looks as though it probably stands yer lordship

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: First Failure?

I too find this discussion fascinating and instructive, just wondering about the best effective cooling system for brain overheating.

Two points, the modern thermostat is not really designed for a Major. The original Major version was designed to open and close the bypass port as it worked but this facility is not on the modern 'stat.

The Diesel Major did have radiator shutters, they were deleted around 1956. Cost saving decision.

Two points, the modern thermostat is not really designed for a Major. The original Major version was designed to open and close the bypass port as it worked but this facility is not on the modern 'stat.

The Diesel Major did have radiator shutters, they were deleted around 1956. Cost saving decision.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: First Failure?

Maybe I'm just lucky with cooling but I definitely needed the hotter stat to get anything like a good running Temp and to stop my fordson slobber.

Like Adrian said though it is fresh out of rebuild. Having had the Rad pro refurbished, block sent away, cleaned, new hoses and a new water pump. I'd stick my neck out and say I have a factory fresh cooling system. It's definitely overcooked. Maybe I should say definitely overcooled for the UK.

Like Adrian said though it is fresh out of rebuild. Having had the Rad pro refurbished, block sent away, cleaned, new hoses and a new water pump. I'd stick my neck out and say I have a factory fresh cooling system. It's definitely overcooked. Maybe I should say definitely overcooled for the UK.

Re: First Failure?

A fellow, do yo say so?, at the Swedish forum did just an interesting observation. The water holes in the new headgasket are smaller than the original. He had been noticing that some newly renovated motors run hot. This could be an explanation. He filed them to original diameter.

Pictures can be seen here:

http://www.fordson.se/phpBB2/viewtopic.php?f=5&t=12839

I myself got a faulty termostat so the motor went never hot. Upon changing i noticed that the place for the tremostat was a bit corroded so i replaced it with one for a Volvo B18 88°, that has a rubber gasket around the flange. Now it runs at the right temperature. At least in this winter.

Pictures can be seen here:

http://www.fordson.se/phpBB2/viewtopic.php?f=5&t=12839

I myself got a faulty termostat so the motor went never hot. Upon changing i noticed that the place for the tremostat was a bit corroded so i replaced it with one for a Volvo B18 88°, that has a rubber gasket around the flange. Now it runs at the right temperature. At least in this winter.

1958 Major

1953-59 mix with backhoe Hymas type 3 (project)

1961Selene 4wd (project)

1953-59 mix with backhoe Hymas type 3 (project)

1961Selene 4wd (project)

Re: First Failure?

Certainly the cooling system of engines is an interesting, as well as important, subject. As far as the diesel engine is concerned you may be interested it the following 2 extracts from research papers:

Combustion in diesel engines is very complex and until recently, its detailed mechanisms were not well understood. For decades its complexity seemed to defy researchers’ attempts to unlock its many secrets despite the availability of modern tools such as high speed photography used in “transparent” engines, computational power of contemporary computers, and the many mathematical models designed to mimic combustion in diesel engines. The application of laser-sheet imaging to the conventional diesel combustion process in the 1990s was key to greatly increasing the understanding of this process.

(c) Coolant Temperature. Ignition delay increases with increase in coolant temperature. Increase in coolant temperature tends to decrease the heat transfer from the combustion chamber, thus producing higher cylinder air temperature, as a consequence the difference in temperature increases.

I could not find, in the last quoted paper, the temperature upswing where combustion becomes critical

Combustion in diesel engines is very complex and until recently, its detailed mechanisms were not well understood. For decades its complexity seemed to defy researchers’ attempts to unlock its many secrets despite the availability of modern tools such as high speed photography used in “transparent” engines, computational power of contemporary computers, and the many mathematical models designed to mimic combustion in diesel engines. The application of laser-sheet imaging to the conventional diesel combustion process in the 1990s was key to greatly increasing the understanding of this process.

(c) Coolant Temperature. Ignition delay increases with increase in coolant temperature. Increase in coolant temperature tends to decrease the heat transfer from the combustion chamber, thus producing higher cylinder air temperature, as a consequence the difference in temperature increases.

I could not find, in the last quoted paper, the temperature upswing where combustion becomes critical

Re: First Failure?

To continue with this laptop that appears to have a mind of its own [yes I know -- a workman should never blame his tools -- but ...]

All engines, diesel or petrol, of the same make and type are different -- even new ones. If one factors in things like fair wear an tear; ambient temperatures that can vary by as much as 20 C during the year; plus a work load that can vary from light duty to extended heavy usage; the miracle is that we can find a single control item, such as a thermostat, that allows our tractors to be operated successfully under such diverse conditions. If we have, be thankful.

As far as I'm concerned it's "praise the Lord and pass the ammunition" --diesel.

Pavel

All engines, diesel or petrol, of the same make and type are different -- even new ones. If one factors in things like fair wear an tear; ambient temperatures that can vary by as much as 20 C during the year; plus a work load that can vary from light duty to extended heavy usage; the miracle is that we can find a single control item, such as a thermostat, that allows our tractors to be operated successfully under such diverse conditions. If we have, be thankful.

As far as I'm concerned it's "praise the Lord and pass the ammunition" --diesel.

Pavel

-

oehrick

- Site Governance Team

- Posts: 1239

- Joined: Wed Jan 29, 2014 2:41 am

- Location: Norfolk Broads UK

Re: First Failure?

A cooling glass of beer via the mouth is generally considered best for the Brain, BrianBrian wrote:I too find this discussion fascinating and instructive, just wondering about the best effective cooling system for brain overheating.

Two points, the modern thermostat is not really designed for a Major. The original Major version was designed to open and close the bypass port as it worked but this facility is not on the modern 'stat.

The Diesel Major did have radiator shutters, they were deleted around 1956. Cost saving decision.

Glad I'm not entirely imagining the bypass and didn't realise some early diesels were shuttered as well, never thought it did anything for the look although the down exhaust and indoor intake did give a nice sleek bonnet (hood) line I think the later arrangements made it look as near perfect as any tractor looked.

Best regards

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Rick - Bogside on Bure

1958 Diesel E1A Mk2 s/n 1470165 - still in working clothes

Re: First Failure?

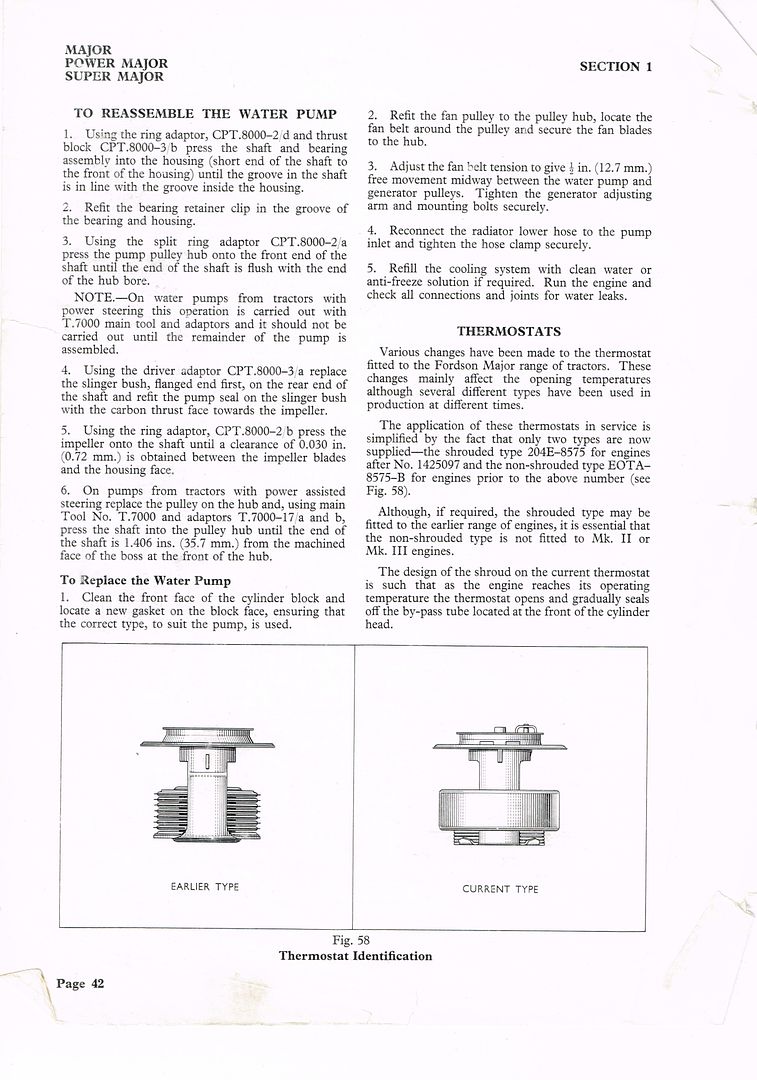

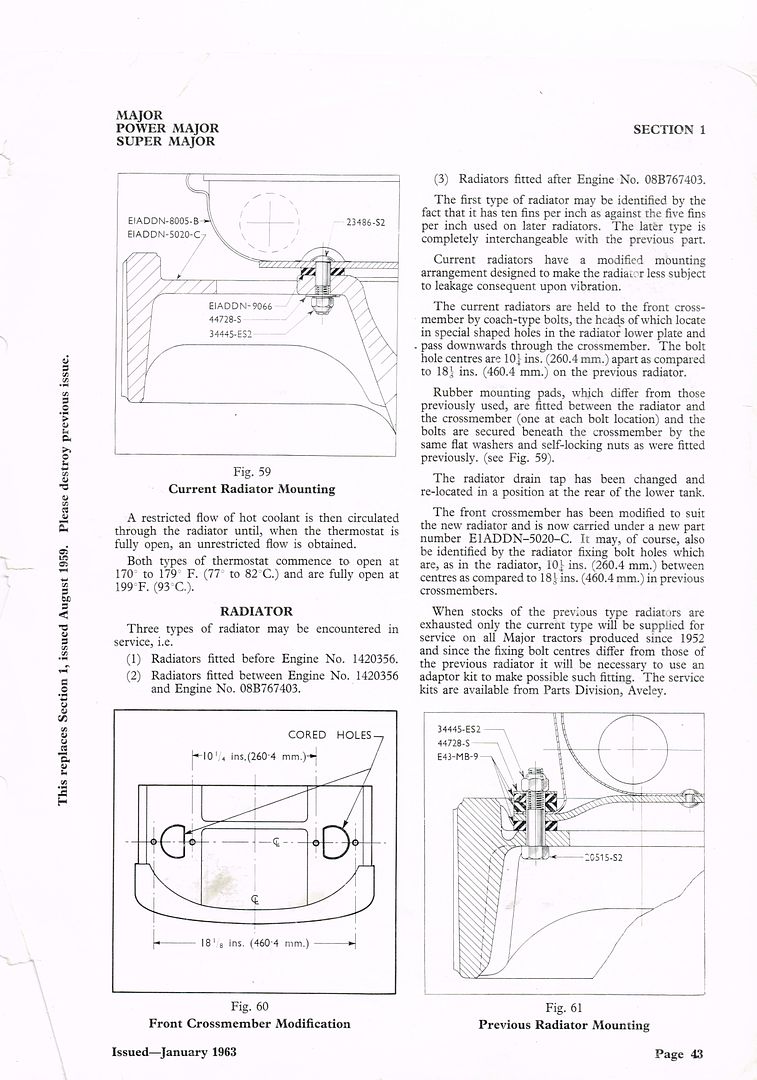

Excerpts from the Service manual giving thermostat data. The new design of thermostat does not close off the bypass perhaps leaving a route open for water and not putting as much flow through the radiator. Thoughts?

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: First Failure?

Never noticed that before, Brian, but the shrouded thermostat was coded 204E which means it was introduced for the Mk. 2 [4 cylinder] Consul in the late 50s. Also it had a Jiggle pin inserted into the base plate to allow any air trapped around the cylinder walls to exit to the radiator whilst the stat. was closed -- a great help when re-filling a system. Without them we drilled a 1/8th hole in the plate.

We were taught that a bye-pass system, either to the engine block or to the rear of the cylinder head, was to eliminate hot spots forming in the upper regions of the coolant. Almost always vehicles, cars, tractors, trucks etc. are driven away shortly after starting. This means that fan blown and ram air keeps the front part of the engine cooler than the rear end until the thermostat starts to open. Bye-pass systems were meant to equalise this heat difference.

Interestingly modern stats are the Waxstat type which are much more stable in operation than the old bellows type which were affected by pressure differences causing them to fluctuate open and close slightly.

Pavel

We were taught that a bye-pass system, either to the engine block or to the rear of the cylinder head, was to eliminate hot spots forming in the upper regions of the coolant. Almost always vehicles, cars, tractors, trucks etc. are driven away shortly after starting. This means that fan blown and ram air keeps the front part of the engine cooler than the rear end until the thermostat starts to open. Bye-pass systems were meant to equalise this heat difference.

Interestingly modern stats are the Waxstat type which are much more stable in operation than the old bellows type which were affected by pressure differences causing them to fluctuate open and close slightly.

Pavel

Re: First Failure?

Another interesting post Pavel, we were taught that the by-pass was to allow the water to circulate around the engine to bring it up to operating temperature quickly and evenly without going through the radiator, so increasing the time taken to reach optimum temperature.

I do not have a thermostat in any of my tractors. I use the radiator shutters on the Major, Dotty hates a thermostat and blows the water out when I fit one but gets up to temperature quickly without much variation. Nuffy has the strange English way of drawing air in from either side of the fuel tank via grills on the side. She too warms up quickly and maintains the correct operating temperature. I have pressure caps on all of them and Nuffy has the separate expansion tank as per most BMC products of the era.

I do not have a thermostat in any of my tractors. I use the radiator shutters on the Major, Dotty hates a thermostat and blows the water out when I fit one but gets up to temperature quickly without much variation. Nuffy has the strange English way of drawing air in from either side of the fuel tank via grills on the side. She too warms up quickly and maintains the correct operating temperature. I have pressure caps on all of them and Nuffy has the separate expansion tank as per most BMC products of the era.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

Re: First Failure?

It would appear, Brian, that our learning years in the 50s were very similar in that we were taught that bye-pass systems played had an important part to play in the warming cycle. Nice to know that in this modern era it is still accepted as essential.

I admit to being quite surprised that you are able to successfully run your tractors without thermostats -- given the vagaries of the UK weather. [Anything to do with global warming ha ha??]. One dodge I was taught early on -- if one was strapped for cash [as I frequently was] and a thermostat gave up the ghost -- was to remove the working parts in the middle, and to re-fit the flange only. This had the effect of maintaining the water flow pressure; rather like placing ones finger over the end of a garden hose -- the water spurted further.

I do wonder, though, if some of us place too much emphasis on the need to have the absolute optimum on coolant temp. control. Your experience would appear to reinforce my belief.

Adrian. I do wonder if your quotes from the diesel site have much relevance to our somewhat older technology Fordsons. Modern diesel engines have compression ratios in the region of 25:1 whereas ours are a relatively low 15:1. Their injector pressures are electrically operated and in the region of thousands of psi. Plus their heat exchangers [rads.] are usually of the horizontal type which are very much more efficient than our vertical ones. Overall their combustion temps. are much higher than ours and therefore need higher temp. stats. to regulate and maintain the correct heat output.

Just a thought.

Pavel.

I admit to being quite surprised that you are able to successfully run your tractors without thermostats -- given the vagaries of the UK weather. [Anything to do with global warming ha ha??]. One dodge I was taught early on -- if one was strapped for cash [as I frequently was] and a thermostat gave up the ghost -- was to remove the working parts in the middle, and to re-fit the flange only. This had the effect of maintaining the water flow pressure; rather like placing ones finger over the end of a garden hose -- the water spurted further.

I do wonder, though, if some of us place too much emphasis on the need to have the absolute optimum on coolant temp. control. Your experience would appear to reinforce my belief.

Adrian. I do wonder if your quotes from the diesel site have much relevance to our somewhat older technology Fordsons. Modern diesel engines have compression ratios in the region of 25:1 whereas ours are a relatively low 15:1. Their injector pressures are electrically operated and in the region of thousands of psi. Plus their heat exchangers [rads.] are usually of the horizontal type which are very much more efficient than our vertical ones. Overall their combustion temps. are much higher than ours and therefore need higher temp. stats. to regulate and maintain the correct heat output.

Just a thought.

Pavel.