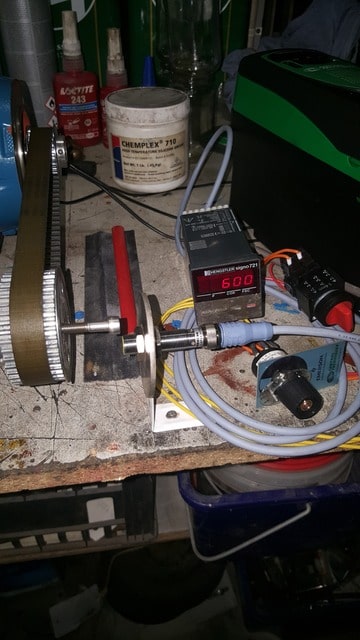

I found an old counter in a box wired it up with a turc sensor and now i was ready for counting revs.

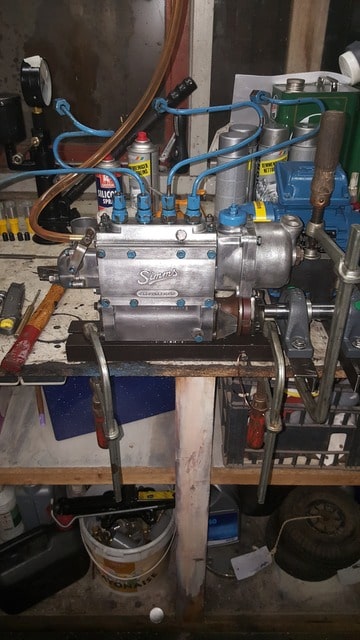

The book says it should be running at 200 rpm but the motor did not agree.

So ended up at setting the inverter at 12hz the lowest it would go and still have torque to pull the pump.

Pump was running 228rpm close enouf in my opinion.

The counter with sensor

Then i created a "specialised" tool to keep the rack in position

I spend about 1 hour getting al four injectors to give the same amount of fuel.

first selected 4 jars that would show the same level with a same amount of fuel.

Then setting the rack a few times.

after i was happy with the results i repeated it at diverent rpm and diverent positions of the rack.

Result

So the rack is set.

At least in my opinion.

Now for the 12cc at 200 rpm and 600 injections.

At this point I discovered it was 200 injections at 600 rpms.

So the low rpm problem I had was not a real problem just having the wrong values in my head

The tip of the medical syringe was in my mind this morning so I went to the laboratory at work and found testtubes with a scale so I borowed 1of them.

I set it a bit over the value quoted in the book I like a bit of black smoke

Next i fitted a new membrame and some other parts so i believe the pump is ready to go.

Only 1 thing that did suprise me after about 10 minutes of running the injectors put pinholes in the rubber hose it is 3mm wall hose............

So watever you do never ever think about touching a running injector.

Ronald

.