Page 1 of 2

My Super Major restoration

Posted: Sun Sep 18, 2016 3:22 am

by lectricman

Well, it finally begins!! I'm starting the restoration of my 1961 Super Major and I want to share it with everyone here. I've had the tractor for about a year, but haven't had the time to tear into it until now. I will try to document everything along the way, and I'm sure there will be lots of questions too! This is my second rebuild on a Fordson, the first being my 1956 Major that I just hurredly threw together. I plan to take my time with the super and hope to have a very nice unit when I'm done. So, without further ado, here we go!

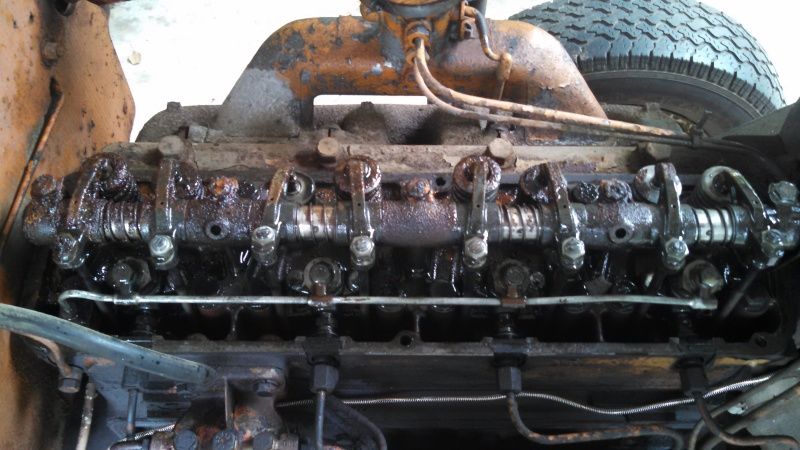

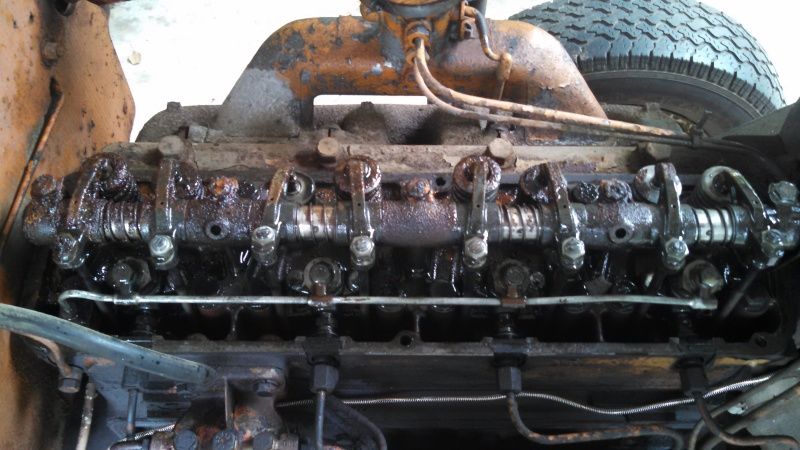

The tractor as it was when I got it:

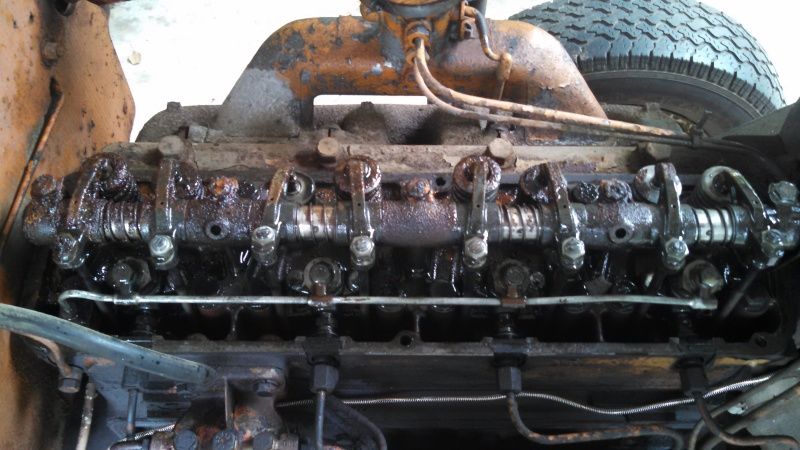

It ran very well for having been sitting exposed to the weather for 8 years prior, but had signs of water intrusion in the top end of the motor:

So the teardown begins!

I found a bent pin and some metal bits in the bellhousing. Apparently one of the pins that holds the clutch yoke to the cross shaft came out and someone fixed it with a bolt:

I haven't tackled disassembling the clutch yet, but found a lot of wear on the levers, looks like the clutch was replaced and not adjusted properly to me.

I will have to pickup here tomorrow, as my laptop is about to die and photobucket just froze up!

More pics to come!!

Re: My Super Major restoration

Posted: Sun Sep 18, 2016 2:31 pm

by AdrianNPMajor

Hello Lectricman

Taking photos at every stage is not just good for us onlookers, which it is, so thanks very much.

Taking photos gives you a record of what you find, thereby providing you with a crucial database for the rebuild.

You are going to end up with a very special tractor.

Could I make a suggestion? Don't paint the tractor. The orange paintwork is wrong, but completely right for your particular Major, because it speaks of your tractor's individual history. Just a suggestion. The counter-argument is just as strong.

Best, Adrian.

Re: My Super Major restoration

Posted: Sun Sep 18, 2016 11:29 pm

by oehrick

Nice start

As for the colour Adrian, perhaps it had been on special secret assignment amongst a herd of Allis Chalmers...............

Re: My Super Major restoration

Posted: Mon Sep 19, 2016 8:42 am

by AdrianNPMajor

You might be right, Rick!

I wonder what the tractor did in the past.

Best, Adrian.

Re: My Super Major restoration

Posted: Mon Sep 19, 2016 8:45 am

by Brian

The tractor comes from Holland and they painted it orange all over to hide the orange grills from me! AAAH HA HA HA!!!!!

Re: My Super Major restoration

Posted: Mon Sep 19, 2016 12:18 pm

by ford5000y

oehrick wrote:Nice start

As for the colour Adrian, perhaps it had been on special secret assignment amongst a herd of Allis Chalmers...............

... or Case...

Re: My Super Major restoration

Posted: Mon Sep 19, 2016 10:11 pm

by oehrick

See lectricman, an orange Super and everyone sees it as something unusual and talks about it! cover it in

Empire Blue and its just another Super

I must admit, first glance at the first pic and I thought it was in old primer but its proper paint and doesn't appear to be

blue underneath which begs the obvious question. if it has no

blue anywhere was it shipped as an unpainted skid and who finished it and for what purpose ??

When the 'orange grille mist' has cleared Brian might even remember something from back in the day on orange liveries. Take it you have no history that goes with it ??

Re: My Super Major restoration

Posted: Tue Sep 20, 2016 3:03 am

by lectricman

Haha, I knew the orange paint would get people talking!

Sadly, I don't have any history on it. I found it on craigslist among an ad for "old tractors for sale". The man I bought it from said he had bought about eight years prior with the intention of restoring it and just never got around to it. It was

blue at one time, as I found some traces of

blue on the inside of the side rails. So I guess that means its not a "one off" special. Now, as promised, more pictures!

55 years of built up gunk on the oil pickup!

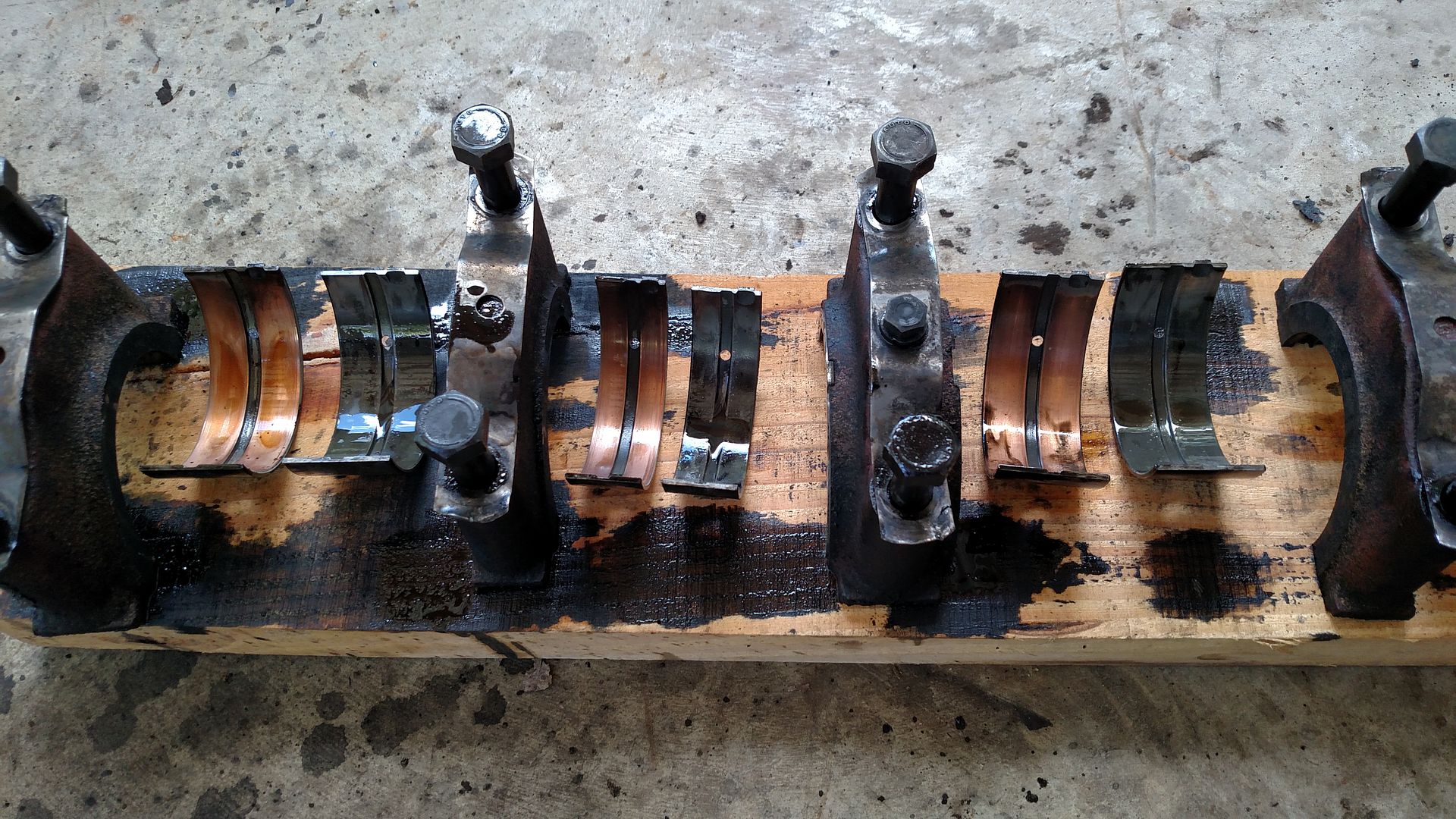

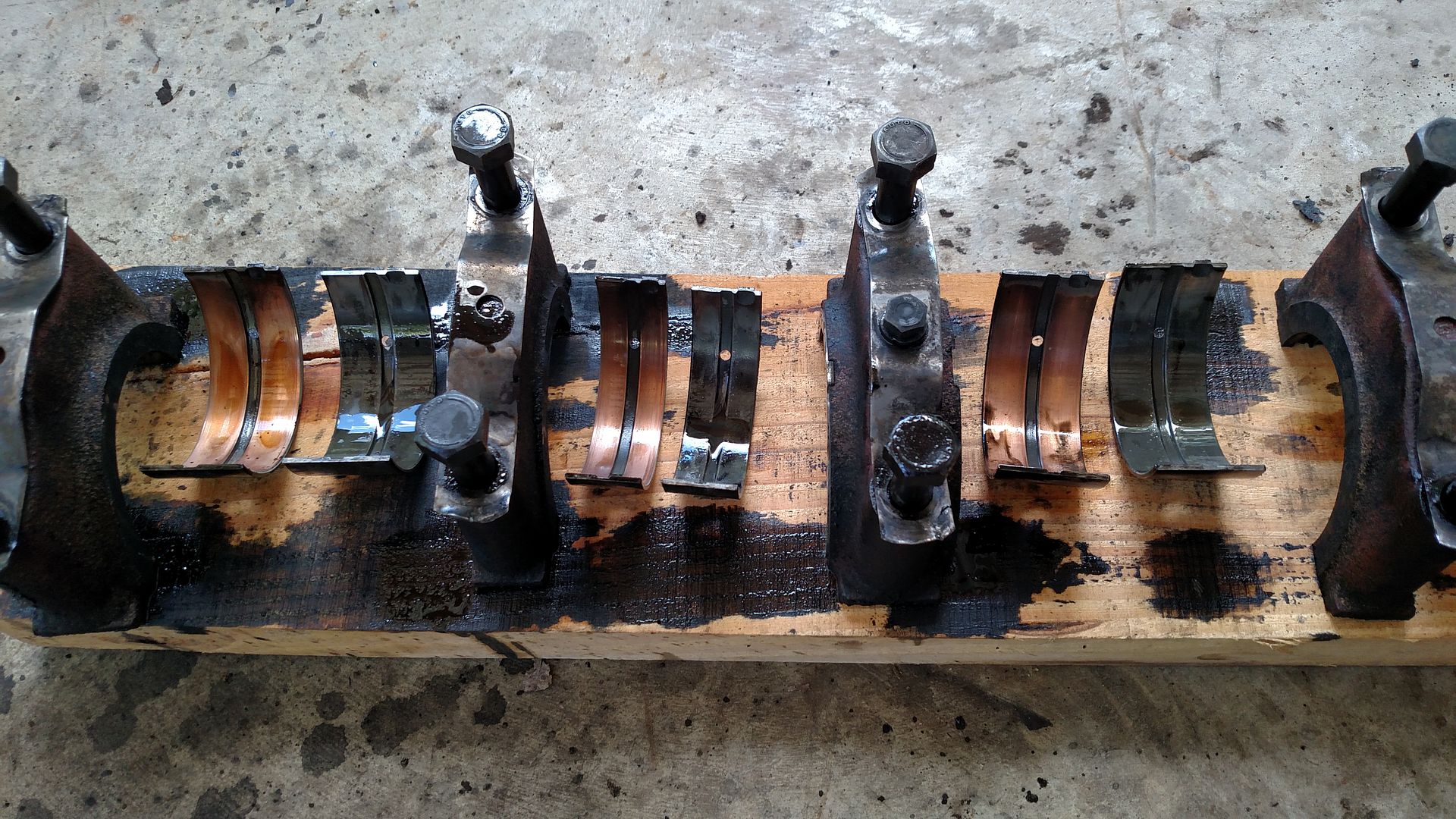

Original main bearings

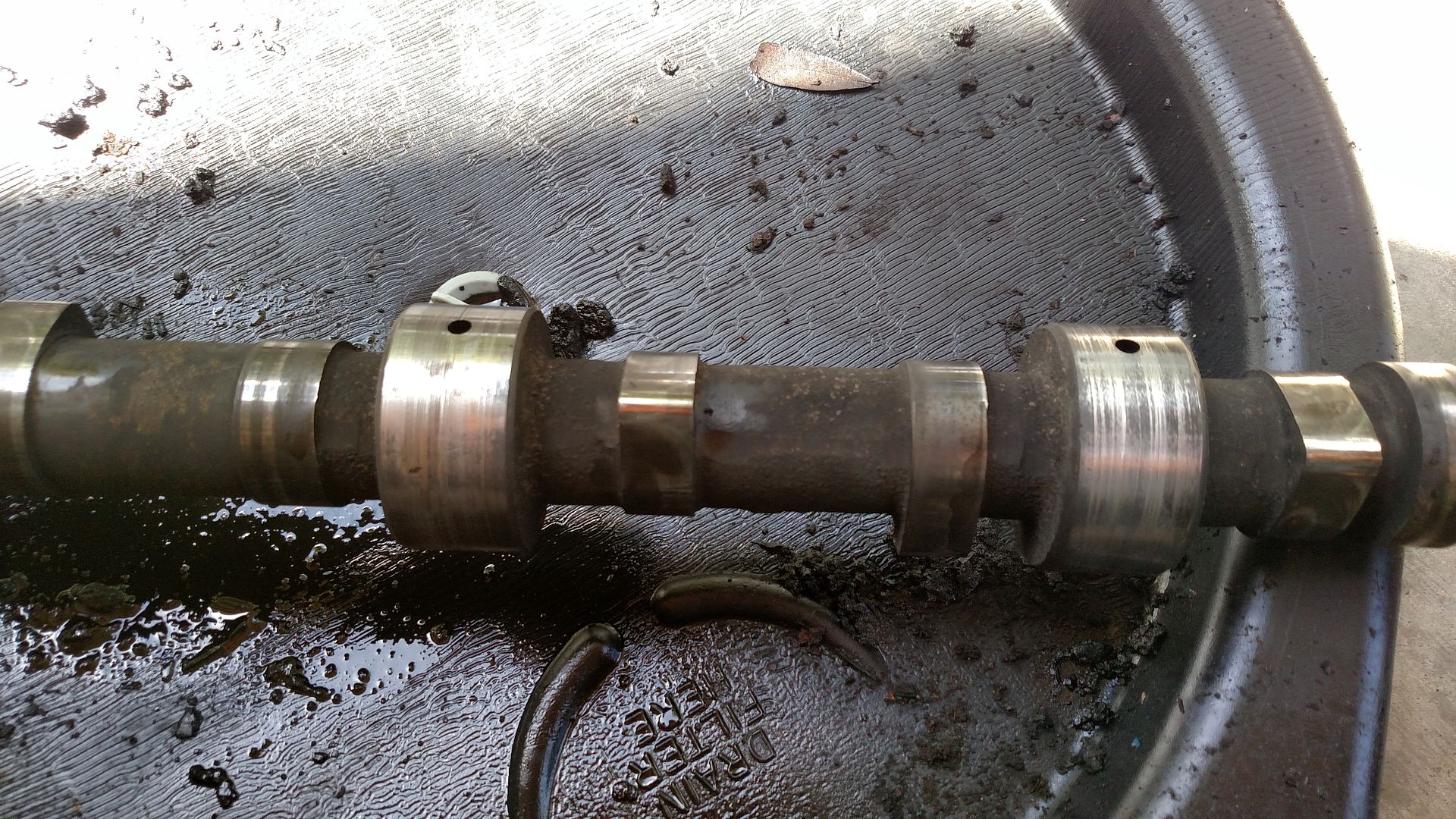

Crankshaft

Each one of the rod journals has a very slight groove that I can just feel with my fingernail, I don't think its bad enough to need machining but am open to suggestions...

Also, there are marks on the number two main journal as seen in the second picture, but I can't feel any change in the surface with my fingernail. What do you guys think?

All of the bearings are std size and original Enfo bearings.

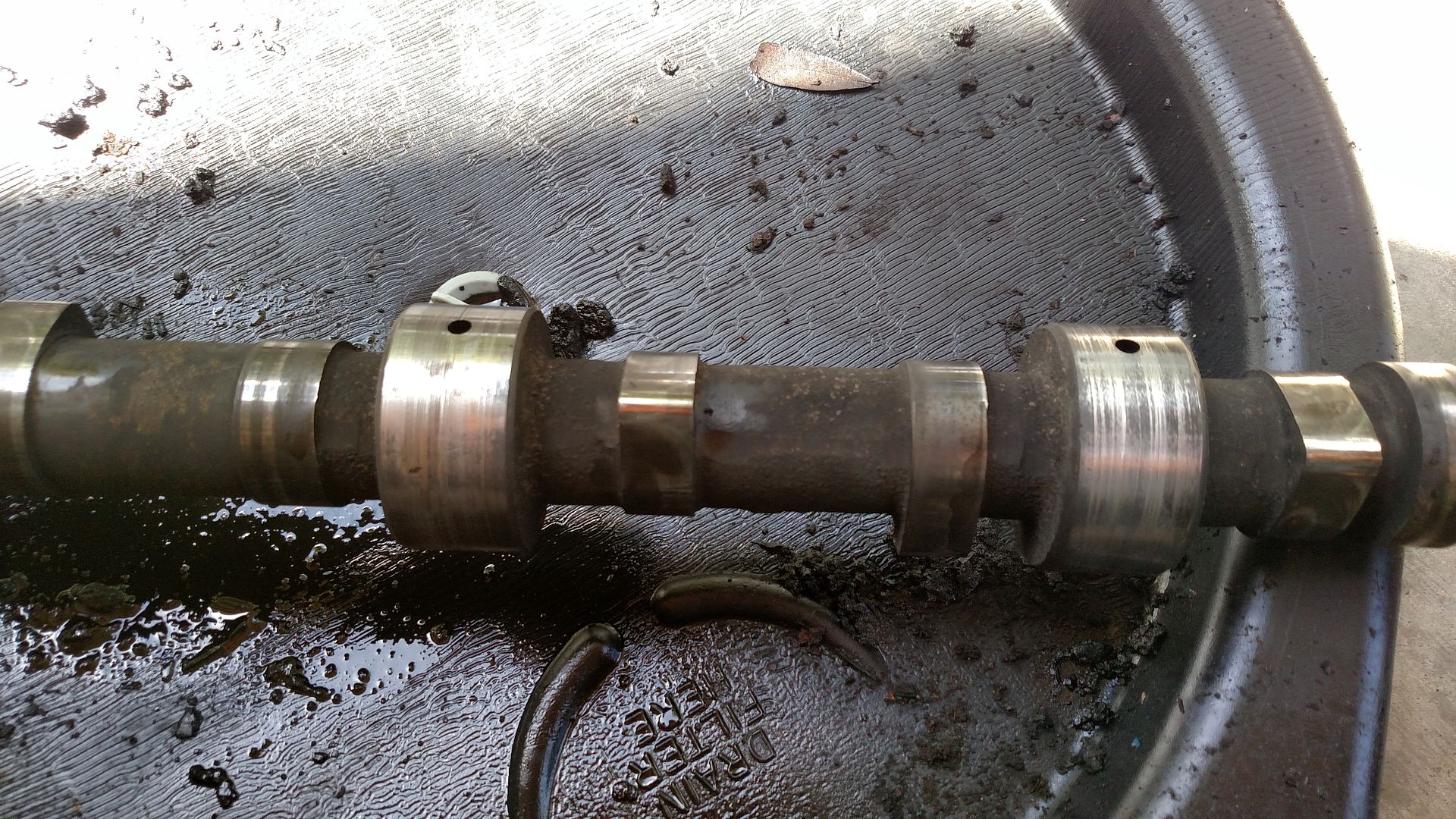

Camshaft

I know these engines did not have replaceable cam bearings, so I hope it will be alright as is.

Now for the ugly part... the number three piston was pretty boogered up around the periphery of the piston top with some of the material burnt or wore off. I found it stuck to the side of the liner:

I had a hard time getting the piston out, which naturally scored up the sides of it on the way out...

Number two was not as bad, but still damaged as well:

I didn't take any pics of the pistons yet.

And I will end it tonight with a question regarding these pictures:

I know these are locating dowels for the head gasket, but how critical are they? I don't remember there being any on my 1956 Major, and these are pretty rough looking. Can they be removed easily or should I just not worry about them?

Re: My Super Major restoration

Posted: Tue Sep 20, 2016 9:06 am

by Brian

She has done a lot of work!

Major engine overhaul is called for, I would get the crank reground and new bearings. With that much copper showing it would be a false economy not to regrind.

Some of those engines had bearings on the cam shaft so that could be worth looking into. Could involve line boring the camshaft journals to have them fitted. Camshaft bearing wear will have an affect on your oil pressure.

Pistons and liners are available at a reasonable price from the after market suppliers.

The head bolt dowels are important on these engines, they should be quite easy to fit as they just push into the block about 1/8th of an inch. they ensure that the gasket does not get dislodged when fitting the head. ( Nuffield tractors have two round headed screws to hold their head gasket in place ). Do not forget the little rubber oil seal between the head and block.

Joking aside about the colour, over here Balfour-Beatty, Kier and Wimpy all painted their tractors orange for work on building sites or construction projects, if she was owned by any similar company during her working life it could explain the state of the engine.

Re: My Super Major restoration

Posted: Wed Sep 21, 2016 2:44 am

by lectricman

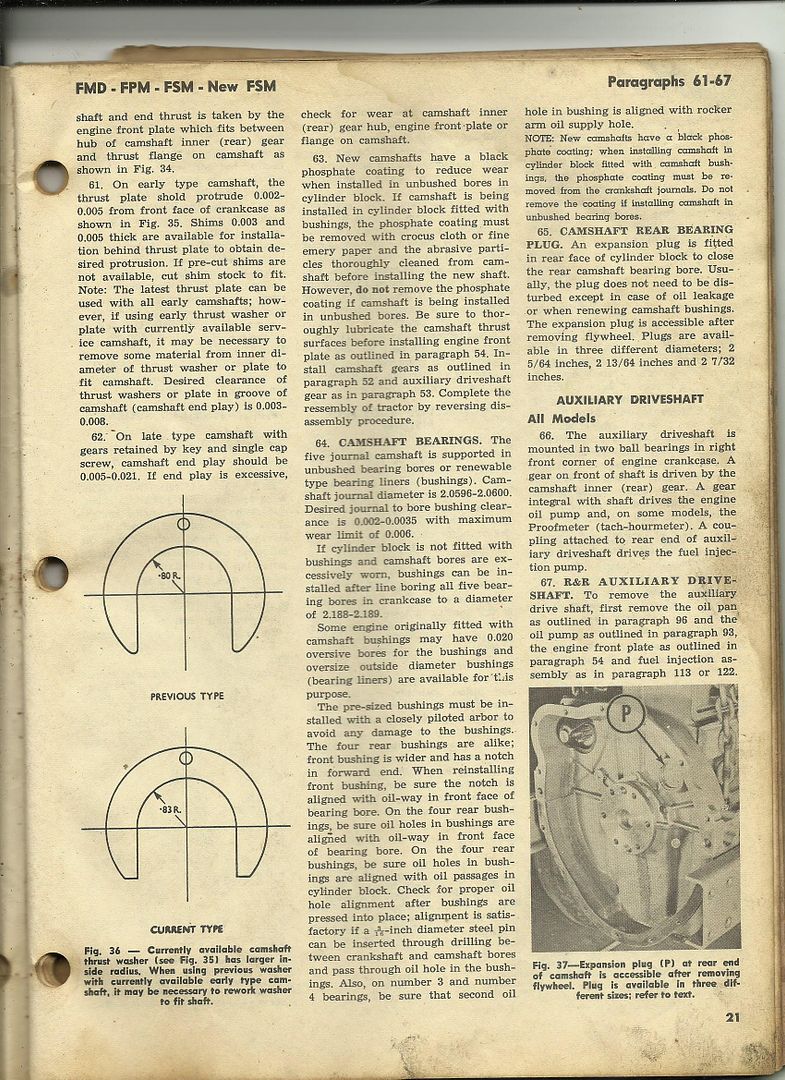

I still need to measure the crank journals with a micrometer to see how worn they are. I have not been able to find any place that supplies cam bearings for these engines. There are none in the engine now, and I know it would need to be line bored to fit them. My question is, what diameter should the cam journals measure so I can check them for wear? Also in regards to the liners, I seem to remember reading on this site that the later liners with two O-rings are slightly larger in diameter, and that most of the engine kits available use this size liner even though they are not correct for the early engines with one o-ring. On my 1956 Major, I used a rebuild kit from Agriline and I had to press the liners in with a 20 ton jack because they were so tight. I used a lot of soap on the o-rings and so far have not had any problems with them. I would prefer to have the correct liners for this engine, though. Any thoughts? I have had good luck with Agriline in the past and their prices are some of the best I have found. There aren't many sources in the US for Fordson parts, and when you do find them they are usually very expensive...

On another note, I stumbled across another Major yesterday while at work! The poor thing has been sitting out next to the guy's barn for a couple years with grass growing up around it. I asked him what the story was on it and he said that it ran when parked, but something had gone wrong with the clutch. It's a Power Major with live drive and is mostly compete, except it has an FL head on it and rear fenders from a 000 series ford. The battery was dead, so couldn't try starting it. Pulled the engine dipstick and found decent looking oil, opened the oil fill and looked at the rockers; they looked pretty clean. However, the backend dipstick was bone dry and rusty. He said he wanted $500 for it, but I passed. I don't think its going anywhere anytime soon, so I'll probably give it a couple months and offer him $250. Hopefully he'll bite on it.

Re: My Super Major restoration

Posted: Wed Sep 21, 2016 8:08 am

by Brian

Agriline now do both liners, the one you need is 7071 if it is a single "O" ring or 7072 for the double. The liners should push in with your hand, if they are tight it means the "O" ring grooves are not clean enough or you have the wrong liner.

You will also need to check the liner protrusion above the face of the block, should be 0.002" to 0.004". Check this before fitting the "O" rings so you can remove and replace the new liners easily. You may have to make new shims if you need them or check the local John Deere agent as they use similar shims on their liners.

Re: My Super Major restoration

Posted: Wed Sep 21, 2016 9:29 pm

by AdrianNPMajor

I agree with Brian. The tractor has done a lot of work. Unfortunately it has done a lot of work without the proper maintenance being carried out. The engine oil hasn't been changed at the proper intervals.

You need to have the crank ground.

Re the camshaft, the journals are scored, confirming the running of the engine with dirty oil. You need to replace the camshaft. Use this as the datum for measuring the camshaft bearing surfaces in the block. I don't know the desirable clearance between journal and bearing surface, but your local engine repair shop will advise. If you're lucky, the cast iron won't have worn. If it has, as Brian says, the journals will have to be line bored so that bearings can be fitted.

It's work and expenditure, but you'll end up with a new engine at the heart of a tractor that will be up for any work it was designed for.

Best, Adrian.

Re: My Super Major restoration

Posted: Wed Sep 21, 2016 9:56 pm

by Fordson 60

This tractor has been used or rather abused.

Its going to be a lot of work to get here in tip top shape.

You have to pull the liners and look at the bottom o-ring groove clean them very wel and hope your in luck.

If they are coroded away you might just be wanting to look for another engine.

Ofcourse there are ways to restore the grooves all depends on your skils and the amount of mony you want to spend.

I bought a engine service kit with cilinders pistons valves valve guides valve springs main bearings conrod big and small end bearing and al the gaskets for 400 euro

It was the 1 bottom o-ring cilinder kit

Good luck with the project ill be keeping a eye on this topic.

Wondering about the wheel weight and extra protection on the front. What would it been used for

Re: My Super Major restoration

Posted: Thu Sep 22, 2016 5:24 pm

by SkidRoe

Up here in the Great White North, tractors used for grounds maintenance at airports or for mowing grass along highways were frequently painted a similar colour of orange.

I always though it was funny for them to go to all the trouble of painting a Ford or John Deere orange when they could have just bought an Allis.

Maybe that says something about Allis...

Looks like you have your work cut out for you - maybe you should just go buy the Power Major and give the SM a heart transplant... just a thought.

Best of luck with the project and keep the pic's coming!!

Cheers,

SR

Re: My Super Major restoration

Posted: Fri Sep 23, 2016 3:25 am

by lectricman

Brian wrote:Agriline now do both liners, the one you need is 7071 if it is a single "O" ring or 7072 for the double. The liners should push in with your hand, if they are tight it means the "O" ring grooves are not clean enough or you have the wrong liner.

I saw the listing for the two different liners. It has been several years since I rebuilt the first Major, and I don't remember how many different engine kits they had listed at that time. However, the liners supplied at that time were supposed to be for the single o-ring block, but were very, very tight. Am I remembering correctly that the two o-ring liners are ever so slightly larger in diameter or is that incorrect?

Fordson 60 wrote:This tractor has been used or rather abused.

Its going to be a lot of work to get here in tip top shape.

You have to pull the liners and look at the bottom o-ring groove clean them very wel and hope your in luck.

If they are coroded away you might just be wanting to look for another engine.

Ofcourse there are ways to restore the grooves all depends on your skils and the amount of mony you want to spend.

I bought a engine service kit with cilinders pistons valves valve guides valve springs main bearings conrod big and small end bearing and al the gaskets for 400 euro

It was the 1 bottom o-ring cilinder kit

Good luck with the project ill be keeping a eye on this topic.

Wondering about the wheel weight and extra protection on the front. What would it been used for

I will hopefully be pulling the liners this weekend to check the grooves and be able to properly clean the block. This engine is in MUCH better shape than the one in my '56 Major was before I rebuilt it. That one had lost oil pressure and seized, destroying the crank and bearings. Plus it had already been machined prior to my working on it. It now has .030 mains and .040 rods in it! It does suffer from low oil pressure from the cam being worn, as I didn't have any machine work done on that part of it. Lessons learned. I still haven't been able to find the specification for the cam journal diameters, if anyone could point me in the right direction it would be greatly appreciated!

As far as the wheel weights and grill guard, I have yet to see a Major near my part of the world without weights. The grill guard appears to be homemade, but is very stout and will soon find a home on my '56 so that I can fit a front loader on the Super.

SkidRoe wrote:Up here in the Great White North, tractors used for grounds maintenance at airports or for mowing grass along highways were frequently painted a similar colour of orange.

I always though it was funny for them to go to all the trouble of painting a Ford or John Deere orange when they could have just bought an Allis.

Maybe that says something about Allis...

Looks like you have your work cut out for you - maybe you should just go buy the Power Major and give the SM a heart transplant... just a thought.

Best of luck with the project and keep the pic's coming!!

Cheers,

SR

I am actually looking forward to the work ahead; the engineering and design put into these machines are not something you find in today's tractors. I'm proud to be able to keep them working. And believe me, I would love to have the Power Major, too!

Re: My Super Major restoration

Posted: Fri Sep 23, 2016 8:26 am

by blackbob

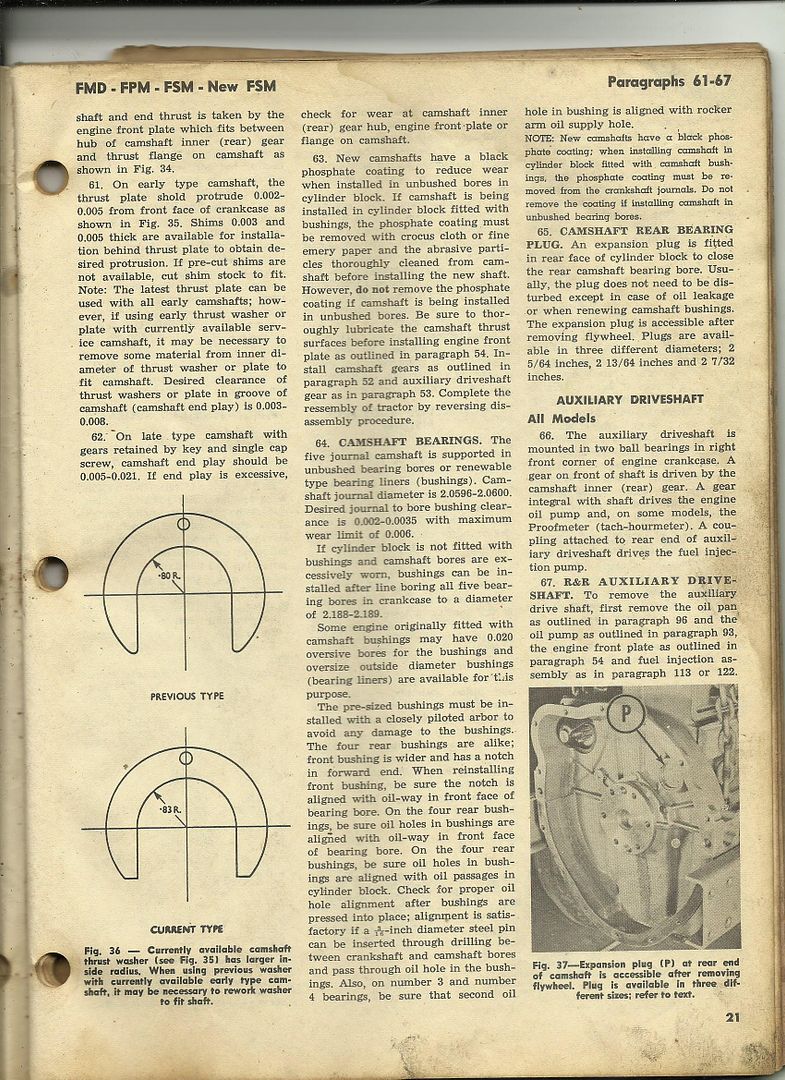

From an I&T 'shop' manual from your side of the pond - we often scan and post stuff like this on the Farming Forum, I don't know if there are copyright issues, this book is 25 years old but maybe still available?

Re: My Super Major restoration

Posted: Fri Sep 23, 2016 8:30 am

by Brian

The liners with two "O" rings were slightly thicker and had the machined area at the top for the second "O" ring. A few years ago, most aftermarket companies were selling this liner for everything it is only in the last few years that the single "O" ring version has started to appear. The double "O" ring is for New Performance Supers only.

What oil do you use? I used to use a modern 15/40W in all my tractors but found that I got low oil pressure and a lot of leaks. I changed to Morrises 20/50W, the oil pressure went up from 10 psi hot to 30 psi hot and I mean HOT. Henrietta is a petrol/kerosene and she runs hot enough to see the manifold glowing on a dark night. On the Nuffy, the timing cover oil seal leak dried up too.

I too did the crankshaft and bearings but left the camshaft so still have a 64 year old cam and oil pump and Henrietta is not a "Show Queen".

The "FL" head on the PM is worth nearly as much as he was asking for the tractor!

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 3:12 am

by lectricman

I'm glad to hear that about the liners! I too have 15w40 in the '56 and plan to try something different when I change the oil next time. I don't know if Morrises is available over here, but I will look into it. Tractor Supply locally carries a wide variety of straight grade oils that are supposed to be pretty good as well. The value of the FL head definitely puts things into a different perspective on the subject of the PM!!

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 3:16 am

by lectricman

Forgot to mention, thank you to blackbob for posting that! It is exactly what I was looking for.

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 8:29 am

by blackbob

lectricman wrote:Forgot to mention, thank you to blackbob for posting that! It is exactly what I was looking for.

They have lots here, but not the 'right' one - I have 2, one for the Major series on its own, and also a thicker one including other Ford models. Very concise and useful manuals, written for people with mechanical ability: although, published in the US so only for models available there - and the spelling is awful

http://www.ebay.com/bhp/i-t-manual

http://www.ebay.com/bhp/i-t-manual

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 12:50 pm

by lectricman

Just ordered one from eBay, a 1967 original for all of the Major series. Thanks again!

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 8:22 pm

by lectricman

Any suggestions for removing the liners? I have a homemade tool that is similar to the factory tool, but these things aren't budging! I'm concerned about damaging the top of the engine block with the tool. I have tried applying heat with a propane torch around the top and bottom of the liner. Any other tips would be great. Thanks!

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 8:48 pm

by AdrianNPMajor

Hello Lectricman

Tighten the nut at the top of the puller, then apply a shock force at the base by clouting the T bar with a lump hammer.

The aim is to proceed millimetre by millimetre. Each time you hit the T bar, go back to tightening the nut. You will find that you will gain another half turn on the nut.

Mine were excessively tight, but they all succumbed to this technique.

Tight because of accretion of gunge. As Brian has advised, installing the new liners, after you have cleaned the empty block (wire brush on an electric drill works well), is quite a different matter - they should just drop in (without the O ring fitted).

Best, Adrian.

Re: My Super Major restoration

Posted: Sat Sep 24, 2016 11:52 pm

by lectricman

Thanks, Adrian. That's pretty much what I was doing until the top of my puller started spreading and bending. I'll be adding reinforcement to it in the morning and try again.

Re: My Super Major restoration

Posted: Sun Sep 25, 2016 12:19 am

by oehrick

Best thing for lubricating the nut / screw is an old tallow candle (or tallow soldering flux) it extends the load at which they finally seize together

I go along with the impact under load method too

Remember my specs and have yer goggles on

More pics to come!!

More pics to come!!