Page 1 of 1

Shaft Straightening for PTO wood chipper

Posted: Mon May 15, 2017 4:25 pm

by American

Hello all, new tractor owner here (1959 Dexta) and I have my first implement repair to attempt.

I purchased a second hand 8" PTO wood chipper from a guy in Oregon who apparently never sized his PTO shaft, resulting in binding and a bent Jack Shaft.

Video of bent shaft;

https://www.youtube.com/watch?v=wr6E0YebQSM

After contacting several machine shops, and getting a response from only one of them, I was told I could expect a repair bill of up to $500. Well, I can buy the tools to fix it for less than that.

So that's what I did. I took advantage of a Mothers Day sale at Harbor Freight to pick up a 20 ton shop press and a clamp on dial indicator, and sourced a couple of V-Blocks from Amazon.

Also found this as a guide, which I will reference in my repair;

http://www.repairengineering.com/shaft- ... ening.html

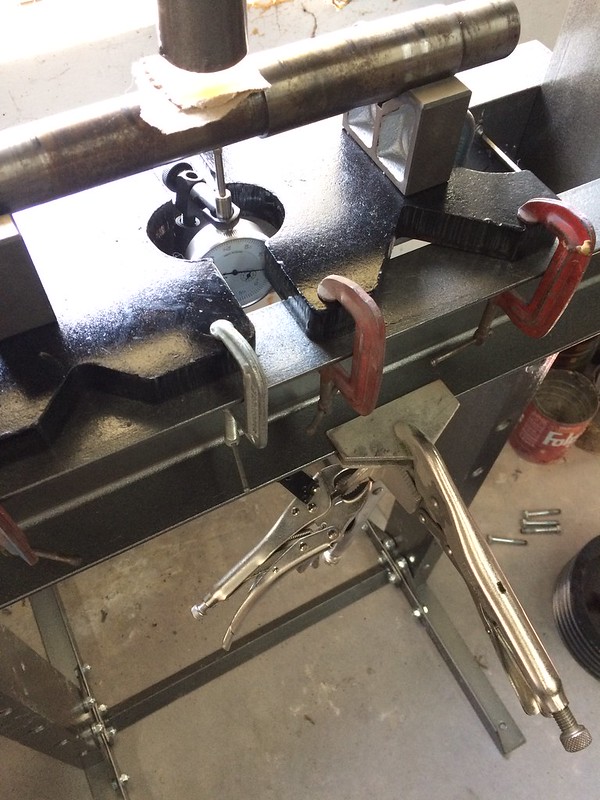

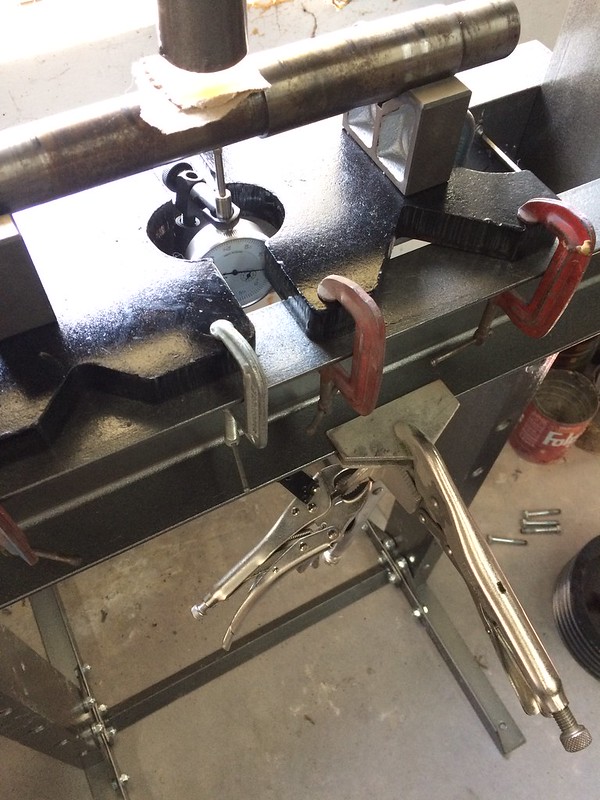

So far, I've assembled my shop press, and disassembled the shaft assembly;

Untitled

Untitled by

CASEY, on Flickr

Untitled

Untitled by

CASEY, on Flickr

Untitled

Untitled by

CASEY, on Flickr

I expect to receive my V-Blocks tomorrow, which should allow me to proceed with the appropriate repair procedures.

If anyone has any advice, I'm open ears, this will be my first attempt at a shaft straightening. I know quite a bit about working with sheet metal, as I am a professional auto body man, and painter, but this is a bit outside of my experience zone, so I'm just seeking out anecdotes from those who've been there and done that.

Re: Shaft Straightening for PTO wood chipper

Posted: Mon May 15, 2017 8:28 pm

by henk

Be carefull, you can end up with two halfs.

Bin there done that.

The shaft is hardened so it will not bent easy.

Re: Shaft Straightening for PTO wood chipper

Posted: Mon May 15, 2017 8:55 pm

by American

henk wrote:Be carefull, you can end up with two halfs.

Bin there done that.

The shaft is hardened so it will not bent easy.

How can I tell if it's hardened? It's off a Chinese made machine that doesn't cost much new. Something that big, if it's hardened, you would think would destroy the PTO shaft before it bent, no?

For reference, this is the implement:

http://www.woodmaxx.com/WM_8M_Mechanica ... /wm-8m.htm

Re: Shaft Straightening for PTO wood chipper

Posted: Mon May 15, 2017 11:39 pm

by oehrick

Consider using a third vee block underneath the press ram, (or at least a slip of leather or fibre) which may reduce the natural tendancy of the shaft to rotate.

If an ordinary file will barely or not touch the metal then Henk is right to warn about the hardness, however it may well be surface hardness - assume you are going to try to straighten cold ?

I'd be more concerned about stressing that shoulder where the diameter increases, a sharp root there would be a real stress raiser.

The main problem is figuring how far past straight you need to bend it, to spring back straight - you are on your own with that, but a fibre tip pen marked line along the side and a block of wood with a nail through it on the press bed will scribe a before pressure' line that you can test against as you apply pressure rather than trying to 'guesstimate deflection.

Hope its easier than my last one, had a 3 ft dia piston on it, was 3" dia and had about 12 ft of rod sticking out each end - I cheated and had some help from our local BIG electric motor manufacturer - they regularly took a couple of thou out of 2 ft dia shafts and had boring machine you could fit an entire fairground carousel on with space round the edge.

Good luck

Re: Shaft Straightening for PTO wood chipper

Posted: Mon May 15, 2017 11:53 pm

by American

oehrick wrote:Consider using a third vee block underneath the press ram, (or at least a slip of leather or fibre) which may reduce the natural tendancy of the shaft to rotate.

If an ordinary file will barely or not touch the metal then Henk is right to warn about the hardness, however it may well be surface hardness - assume you are going to try to straighten cold ?

I'd be more concerned about stressing that shoulder where the diameter increases, a sharp root there would be a real stress raiser.

The main problem is figuring how far past straight you need to bend it, to spring back straight - you are on your own with that, but a fibre tip pen marked line along the side and a block of wood with a nail through it on the press bed will scribe a before pressure' line that you can test against as you apply pressure rather than trying to 'guesstimate deflection.

Hope its easier than my last one, had a 3 ft dia piston on it, was 3" dia and had about 12 ft of rod sticking out each end - I cheated and had some help from our local BIG electric motor manufacturer - they regularly took a couple of thou out of 2 ft dia shafts and had boring machine you could fit an entire fairground carousel on with space round the edge.

Good luck

I do intend to straighten it cold if the press is up to it. If the press isn't enough, my second option is to attempt to flame straighten it, but I'd rather not.

I have a dial indicator for measurement so I'll be able to measure accurately and bend as needed, I bend tubing and spring-back is usually between 2-4 degrees. I don't know if that helps me beyond visualizing or estimating, but it's there, rattling around in my head.

I plan to map the bend along the shaft, as per the directions I posted earlier.

Lastly, I tried the file test as you suggested. It filed like other mild steels I've messed with. About 10 passes with a fine file produced ample metal shavings. Not that I've ever filed hardened steel from which to compare it, but it files like other mild steel (cars, HREW, DOM, plate) I've worked on.

I'll look around for a strip of leather or something grippy, I won't have a third V-Block.

Thanks for the tips

Re: Shaft Straightening for PTO wood chipper

Posted: Tue May 16, 2017 12:09 pm

by oehrick

A through hardened or case hardened shaft would have the file not taking much if anything off so it sounds as if it has not been through or case hardened.

If you are used to tube bending, other than the force involved you have already got a feel for it, likewise having a clock to measure deflection, I nearly put height gauge or dti in but thought it best to start simple knowing how remote some of you guys over there may be from sources of special ised tools

IF it has not been seriously heat treated in manufacure you are unlikely to spoil it if you do need to cook the shaft, I'd keep to only just visible dull red and keep the heat as far from the splines as possible - old method here for small items was to stick the end needing cooling in a potato - for the larger size perhaps some sort of beet ??

Look forward to hearing its back in the chipper with runout in tenths of a thou

Re: Shaft Straightening for PTO wood chipper

Posted: Wed May 17, 2017 6:58 pm

by American

Welp, got er done this morning. Took less than two hours to map and straighten.

Runout at it's worst spot was .063" After set up and pressing, I got it down to .006" at which point I hit a wall and couldn't improve it any further. Not a problem though, perfectly adequate for the task at hand.

The press, v blocks and dial guage all came in under $200, and now I have tools for doing other projects, so the repair is ultimately free

American maths.

Here is the set up, reference marks along the top with a degree location at the end of the shaft. This ended up being overkill as this was a pretty straight forward fix, but it was good to get the practice and learn something;

Untitled

Untitled by

CASEY, on Flickr

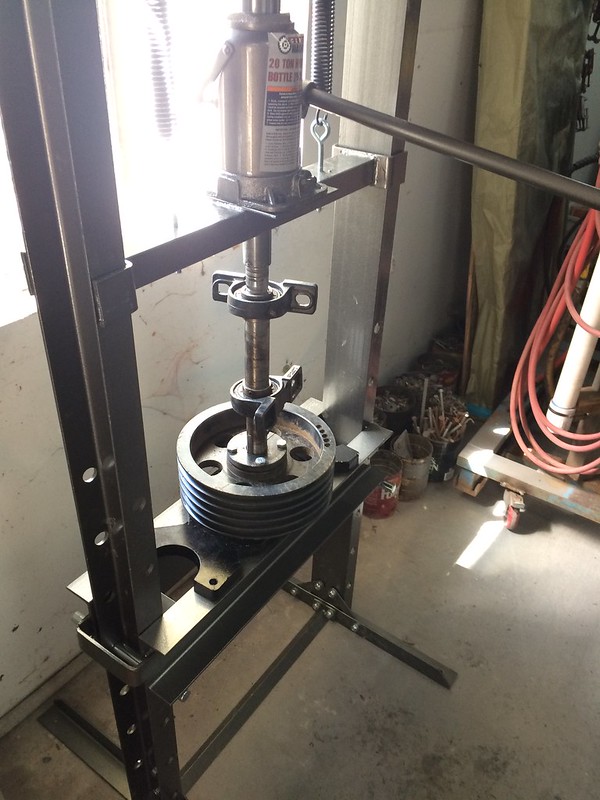

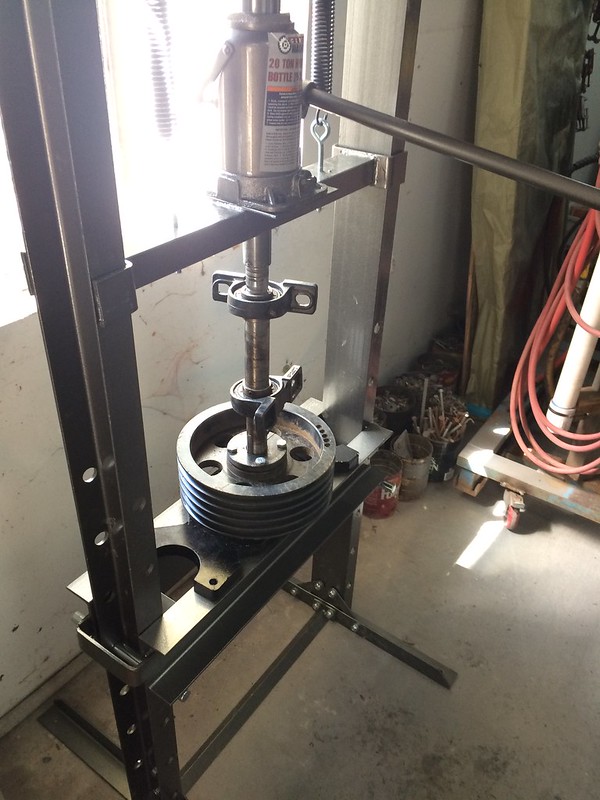

Here you can see I clamped everything down. I started with the press plates, then I set up the v-blocks with a square to get the angle and alignment just right;

Untitled

Untitled by

CASEY, on Flickr

All done and reassembling the shaft;

Untitled

Untitled by

CASEY, on Flickr

Re: Shaft Straightening for PTO wood chipper

Posted: Wed May 17, 2017 9:37 pm

by American

Re: Shaft Straightening for PTO wood chipper

Posted: Wed May 17, 2017 9:49 pm

by henk

Re: Shaft Straightening for PTO wood chipper

Posted: Thu May 18, 2017 1:24 am

by oehrick

Well done from a wet & rainy Bogside too,

I dunno about his maths though Henk (sorry math, they only have the one in the US - must have to share it around

)

$200 outlay on tooling works out free ? despite buying a press with a set of nice flamecut Vee blocks, he goes and buys a set of ground, accurate vees but then stands them on the flamecut ones

I'm not surprised its still as bent as a Waltham Watch

I've known people spend hours trying to chase the last thou or three out of a hydraulic ram when the end to end bore of an old cylinder is unlikely to be that close and seals are made flexible ! I doubt you are likely to suffer any serious ill effects at PTO speed - probably far more wear / runout on the couplings

Nice set up for future problems as you say and you can also do contracting jobs which will make it even cheaper!

Re: Shaft Straightening for PTO wood chipper

Posted: Thu May 18, 2017 1:24 pm

by jdaley

That was an amazing problem and solution, well done

Re: Shaft Straightening for PTO wood chipper

Posted: Thu May 18, 2017 3:20 pm

by American

oehrick wrote:Well done from a wet & rainy Bogside too,

I dunno about his maths though Henk (sorry math, they only have the one in the US - must have to share it around

)

$200 outlay on tooling works out free ? despite buying a press with a set of nice flamecut Vee blocks, he goes and buys a set of ground, accurate vees but then stands them on the flamecut ones

I'm not surprised its still as bent as a Waltham Watch

I've known people spend hours trying to chase the last thou or three out of a hydraulic ram when the end to end bore of an old cylinder is unlikely to be that close and seals are made flexible ! I doubt you are likely to suffer any serious ill effects at PTO speed - probably far more wear / runout on the couplings

Nice set up for future problems as you say and you can also do contracting jobs which will make it even cheaper!

And here I was, more concerned about the machined V-Blocks being cast iron and letting go in a fractured explosion of glory and tears.

The job was free because it's tools, not parts, it's my American capitalist accounting mechanism at play. This is how people like Donald Trump get away with crime long enough to become President.

Re: Shaft Straightening for PTO wood chipper

Posted: Fri May 19, 2017 1:09 am

by oehrick

Thats how I justify any purchases to my wife and to be fair it didn't take her too long to see the logic.

I must own to having a silver soldered back together vee block which was not being used for measuring when it failed

Those flame / plasma cut blocks (which I assume were part of the press kit?) look as if they might bruise a shaft so I can see why you went for something a bit nicer - all you need now is some neighbours with full pocket books and bent crankshafts to fund the next tractor.

Have you run the chipper up as yet and if so how does it sound ? Looking forward to seeing the dexta

Nice to have a win even if the kit to do it cost the thick end of nothing

Re: Shaft Straightening for PTO wood chipper

Posted: Fri May 19, 2017 3:57 am

by American

I ran the chipper the last few days, filled up my truck with wood chips killing full grown manzanita, and pine saplings/trimmings. Works like a champ, eats wood like nothing. Whatever fits in there, its gone. Dexta barely bogs down at all on the biggest stuff. Let me find a pic, it's all over a different thread titled "My First Tractor". I want to sand blast and paint it soon, but it has a good bit of blow by, so I should probably freshen up the motor first and keep the oil changed in the meantime. I have some contract work (I sand blast and paint ag equipment and big rig trailers) coming up soon, so the tractor and yard work projects will all need to take a break so I can go make some more money.

Tractor

Tractor by

CASEY, on Flickr

Tractor

Tractor by

CASEY, on Flickr

Tractor

Tractor by

CASEY, on Flickr

BONUS ROUND. Here's a Hay Squeeze I blasted and painted;

Untitled

Untitled by

CASEY, on Flickr

And a blasted and painted hay trailer, with my beater truck, sand blaster and towable air compressor in the background;

Untitled

Untitled by

CASEY, on Flickr

Here is a pair I did, all stacked up with hay;

Untitled

Untitled by

CASEY, on Flickr

DOUBLE JEAPORDY!!! A 1969 Camaro I restored for a customer, I try to stay away from this kind of work anymore, doesn't pay like it should;

Untitled

Untitled by

CASEY, on Flickr

Re: Shaft Straightening for PTO wood chipper

Posted: Fri May 19, 2017 3:11 pm

by oehrick

You look well geared up for the sheetwork etc when you get round to it, some hard work is the best thing for Fordsons which have been retired or on light duties so if a period of collar work re beds the rings and reduces the smoke it sounds like you have a good one for your first

and if not its one less cylinder than a Major to fix !

Thanks for the photos and delighted the fix worked out so well - one of the beauties of this site is that people will be looking to do the same, find this thread and learn how and gain confidence to have a go instead of buying a replacement.

Cheers & beers

Rick

Re: Shaft Straightening for PTO wood chipper

Posted: Sat Jul 01, 2017 12:50 am

by Jerry Coles

Slight digression but can you give us details of yuor front weight tray please. Looks to be a tidy answer.

Cheers

Jerry

Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr