Page 9 of 16

Posted: Fri Sep 18, 2009 4:57 pm

by Pascal

Thank you, Grani.

I have read it, but due to my lack of experience with these kind of things, I have asked a cousin of mine to help me.

Two know more than one.

I'll keep you updated.

By the way, this is the 200th post on this topic!

Posted: Mon Oct 05, 2009 8:33 pm

by Pascal

Hi guys,

Last saturday my cousin got the cranckshaft and the camshaft out and cleaned them.

As one of the bearings of the crankshaft was damaged, we replaced all the bearings of the crankshaft.

After cleaning, my cousin put both the shafts back in.

Posted: Mon Oct 05, 2009 8:47 pm

by henk

Keep good friends with your cousin Pascal. Nice workshop he has.

Heavy cranckshaft.

Posted: Tue Oct 06, 2009 3:18 pm

by Pascal

Hi Henk,

The crankshaft was quite heavy indeed..about 80 kilograms (kg), I think.

We weighted the engine (without the head). It was 275 kg without the flywheel and 325 kg with the flywheel on.

Posted: Tue Oct 06, 2009 9:33 pm

by Frans

Well lets hope there is no upcoming tax plan for the weight of the tractors

The 6 cylinder symphonie is come a bit closer, next year iff we both finished the job we must meet in between..

Frans

Posted: Wed Oct 07, 2009 3:32 pm

by Pascal

Sounds like a great idea, Frans!

I am looking forward to it!

Posted: Mon Oct 12, 2009 9:39 am

by Pascal

Hi guys,

I am collecting parts in preparation for the conversion from 4 to 6 cylinder.

I have two questions at this moment. I hope you can help me.

1. Is there a gasket between the engine and the gearbox? If so, do I need a paper gasket, or will fluid gasket do fine?

2. What should the oil pressure of an 590E be? Then I can buy the right oil pressure gauge?

Thank you in advance!

Posted: Mon Oct 12, 2009 4:30 pm

by Grani

Pascal wrote:Hi guys,

I am collecting parts in preparation for the conversion from 4 to 6 cylinder.

I have two questions at this moment. I hope you can help me.

1. Is there a gasket between the engine and the gearbox? If so, do I need a paper gasket, or will fluid gasket do fine?

2. What should the oil pressure of an 590E be? Then I can buy the right oil pressure gauge?

Thank you in advance!

1.There is no gasket. 2. A 3 bar gauge is enough. My boat engine had 1,6 bar before and 2,7 bar after the engine rebuild when running at 1700 rpm and at 85 degres celcius

Posted: Tue Oct 13, 2009 12:30 pm

by Pascal

Hi Grani,

Thank you very much for your answers.

About the pressure. What harms an engine more: too high or too low pressure? Which one is more likely to happen?

You mention, your boat has 2.7bar at 1700rpm. Your tractor runs at a higher rpm, you once wrote.

Does your tractor then automatically has a higher pressure? Or has the rpm not much to do with it?

Which part of the renovation of your boat engine do you think is the most important reason, that the pressure went from 1.6 to 2.7?

Or has it to do with the complete renovation?

Posted: Tue Oct 13, 2009 4:45 pm

by Grani

The oilpump has a pressure valve that keeps the pressure at nearly a constant pressure. When the engine is in good condition the bearings let a small but nessesary amount of oil thrugh them to keep them cool. If the bearings are to tight the amount of oil is to small to chill the bearing and in the other hand worn bearings let to mutch oil through so the pump is not able to keep the pressue up. A worn pump and pressurevalve does the job even worse. Oil is thinner when hot and the pressure is allways lower then. How low it goes depends on the general condition of the engine. If the pressure is to high you have a stuck valve or wrong spring in it.

Posted: Wed Oct 14, 2009 8:05 pm

by Frans

Posted: Wed Oct 14, 2009 9:00 pm

by Pascal

Grani,

Thank you for your explenation!

Frans,

That looks great! Thank you for the pictures.

Posted: Sun Nov 01, 2009 8:25 pm

by Pascal

Hi guys,

Here's an update from me.

My cousin and I have been working on the 590e. Slowly it's coming all together.

Posted: Fri Nov 06, 2009 10:46 pm

by Pascal

Hi Grani,

You helped me a lot with this link:

http://www.fordson.se/1A_Motor_Suplemen ... 01-031.pdf

Could you please help me with the next pages (32 and so on) of this book?

I am mounting the noizzles, but I don't know how tight I should pull them. Also for the rocker shaft.

Posted: Sat Nov 07, 2009 7:11 am

by Grani

I don´t have the next pages. Here is an older one if it helps.

http://www.fordson.se/1A_Motorkapitlet_ ... manual.pdf

Here is for the nozzles. 1,86-2,07 Kpm and make sure you have new copper gaskets and the oldones removed from the holes first.

Rockershaft 2,35-3,04 Kpm. Tight them alternately so the shaft won´t bend.

Posted: Sat Nov 07, 2009 10:49 am

by Brian

Those pages are from the Major manual and that is in the manual section on this site. Go to the home page, click on manuals and that will take you though to the manuals on Mike's server. You can download the whole lot from there.

Posted: Tue Nov 10, 2009 10:35 pm

by Pascal

Thank you very much both Brian and Grani!!

Posted: Sun Nov 22, 2009 10:15 pm

by Pascal

Hi guys,

Next week I am hoping to paint my new engine.

After the first paint, I will put the vacuumpump, distribution and flywheel back on.

What's the best order of rank to mount these three?

I have read the posts about the timing on the Major-forum with great interest. I have learned a lot from it.

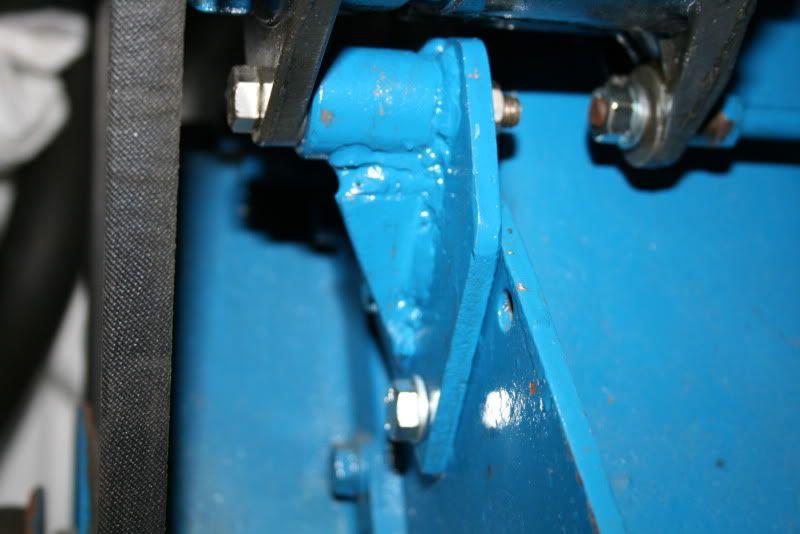

I have noticed, that the coupling of the vacuumpump is different from the 4 cylinder. Can anybody tell me, if this is the correct position for the coupling?

Does anybody knows the order of rank of the cylinders in a 590e?

I think, that in a 4 cylinder it's 1-4-3-2.

Posted: Mon Nov 23, 2009 8:14 am

by Brian

1-5-3-6-2-4. four cylinder is 1-3-4-2

Posted: Mon Nov 23, 2009 10:31 am

by Pascal

Thank you, Brian!

Do you have any advices for mounting the flywheel, vacuum pump and distribution? Which should be on first, for example?

Posted: Mon Nov 23, 2009 3:22 pm

by Brian

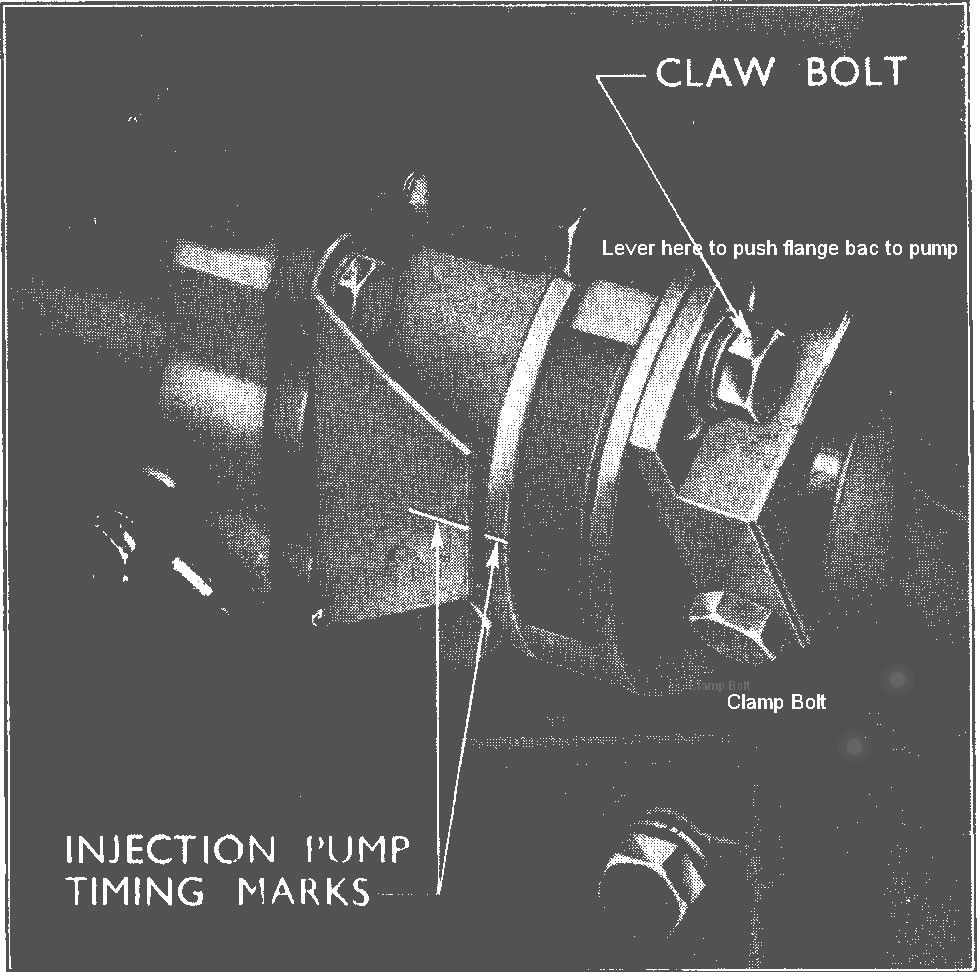

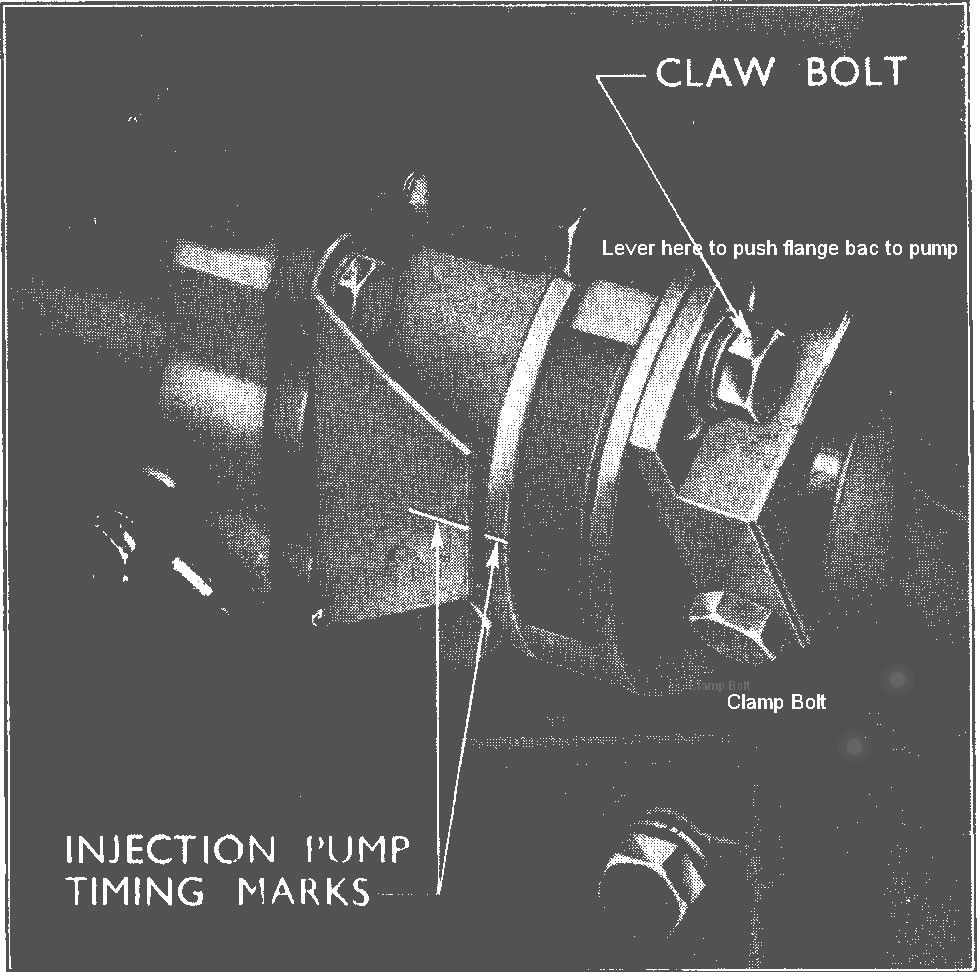

Flywheel first as this will give the setting for the pump. Make sure you are on No.1 when fitting the pump. Your two marks on the pump should be in line when 23 degrees is in the sump inspection port.

Will it be ready to meet us in Museum Plain in Amsterdam next spring?

Posted: Mon Nov 23, 2009 10:16 pm

by Pascal

Hi Brian,

Thank you the advice! What do you mean by "you are on No. 1"? Is the piston supposed to the up or down?

What 's a simple way to see this? I have the engine closed already..

Maybe through the cover assembly of the head?

Or maybe through the inspection port?

I hope it will be ready before next spring!

It would be great to meet you in the centre of Amsterdam on my Fordson!

Guess we have a lot of attention than.

Posted: Tue Nov 24, 2009 9:01 am

by Brian

Because the pump turns at half engine speed, the timing marks on it, line up in two positions, TDC No.1 and TDC No.6.

So, unless you check and are certain, you have a 50/50 chance that the pump is fitted 180 degrees out. This would mean it was injecting on No.6 when No.1 was coming up on its firing stroke.

This has happened many times and caused many hours of head scratching.

The easiest way to check is to look at the pump drive on the engine end. There is a clamp bolt through the coupling where it fits to the drive shaft. When you line up the marks on the fly wheel to 23 degrees, make sure the clamp bolt is under the shaft rather than over it. This means the engine is on the No.1 firing stroke and the pump is too if its marks are lined up.

This problem is there on all Major-based engines.

Posted: Tue Nov 24, 2009 10:28 pm

by Pascal

Hi Brian,

Thank you again for your reaction!

Tommorrow evening I will be working on my engine again. Hopefully I will be able to put the engine on time.

The coupling on my engine looks a little different, but it should work the same, I guess. I will take a look at it and find the marks.

Does "firing stroke" means that the cylinder is on its lowest position?

Posted: Wed Nov 25, 2009 6:56 pm

by Grani

Pascal wrote:

Does "firing stroke" means that the cylinder is on its lowest position?

It means that the piston is at highest position and both it´s valves are closed. It is the firingstroke when the piston goes down from this position.

http://www.youtube.com/watch?v=ERyMKtbe ... re=related