Is there a sealing on this axle and what would be the way to fix this leak. Can't find any thing in the part list.

Oil leak at the fuel pump drive

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Oil leak at the fuel pump drive

The second oil leak is at the fuel pump drive axle coming out of the engine. (lower red line) I've been working on the engine mounting plate and the gear cover plate this winter and had everything removed. Including the front of the tractor. I think that removing the axle would mean to do it all over again.

Is there a sealing on this axle and what would be the way to fix this leak. Can't find any thing in the part list.

Is there a sealing on this axle and what would be the way to fix this leak. Can't find any thing in the part list.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

Hi Henk,

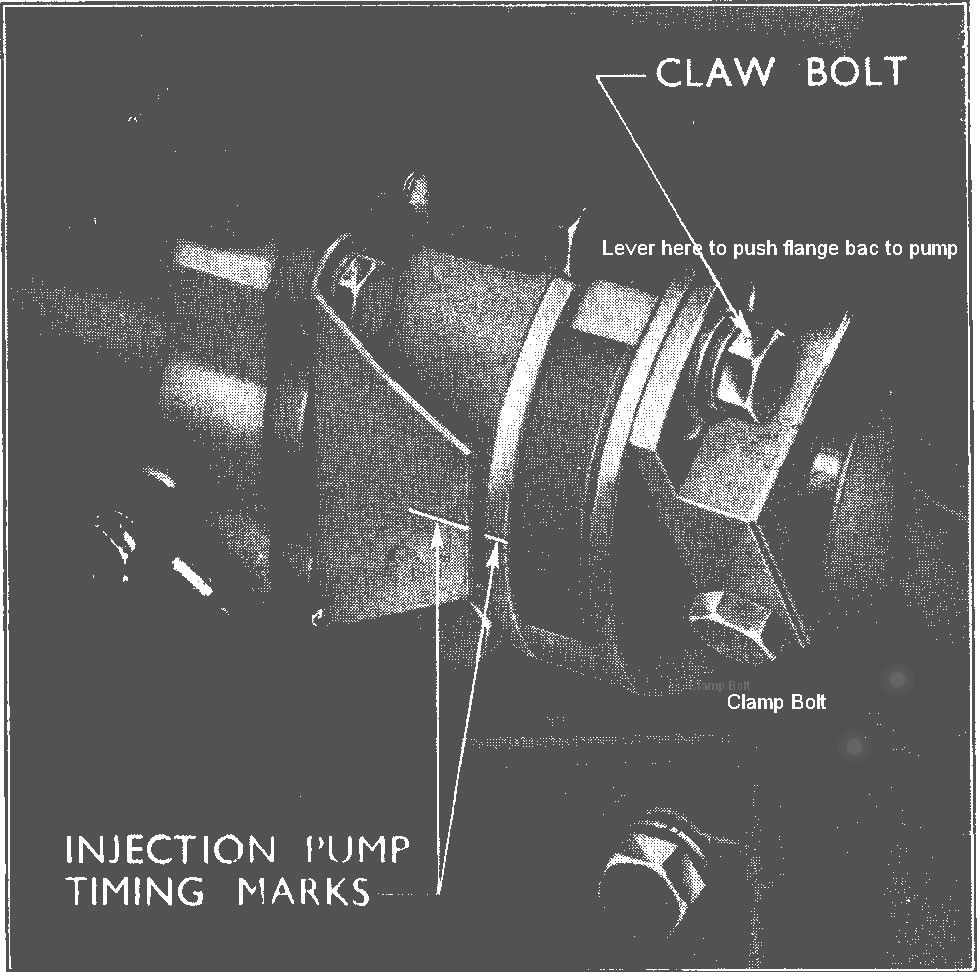

There is an oil seal that can be fitted by removing the injection pump and drive. It has a metal case. Its just a matter of getting it out and fitting a new one. (Sorry about the paint ).

).

There is an oil seal that can be fitted by removing the injection pump and drive. It has a metal case. Its just a matter of getting it out and fitting a new one. (Sorry about the paint

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Thanks Brian and Emiel,

Gives me hope again.

Great pictures Emiel. Shows exactly what to do. Are the measurements not inches instead of mm?

I think I have to use a speedy sleeve on the crankshaft pulley. It’s worn and still leaking with a new seal. I was planning to machine it on a lathe next winter and press a thin bush over it, but this could be the solution.

Gives me hope again.

Great pictures Emiel. Shows exactly what to do. Are the measurements not inches instead of mm?

I think I have to use a speedy sleeve on the crankshaft pulley. It’s worn and still leaking with a new seal. I was planning to machine it on a lathe next winter and press a thin bush over it, but this could be the solution.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

New seal will be on its way to you on Monday Henk, along with some other bits for Dies.

The seal came in the kit of gaskets that I got for Henrietta but did not use as she does not need a seal there, the shaft is inside her governor housing.

The seal came in the kit of gaskets that I got for Henrietta but did not use as she does not need a seal there, the shaft is inside her governor housing.

Fordson Tractor Pages, now officially linked to: Fordson Tractor Club of Australia, Ford and Fordson Association and Blue Force.

Brian

Brian

-

JC

- Site Governance Team & Expert Team

- Posts: 1092

- Joined: Thu Apr 17, 2008 3:48 am

- Location: Montague Calif. USA

Henk

Seals and bearings are often manufactured in mm sizes, even when the rest of the machine is measured in inches. I couldn't find an inch sized seal that would fit, but I can find the exact size in mm.

I have a US-made concrete mixer from the 1940s and all of the bearings in it are mm, even though millimeters weren't used here at that time.

Thanks to Brian, you won't need those measurements, but maybe someone else will.

Seals and bearings are often manufactured in mm sizes, even when the rest of the machine is measured in inches. I couldn't find an inch sized seal that would fit, but I can find the exact size in mm.

I have a US-made concrete mixer from the 1940s and all of the bearings in it are mm, even though millimeters weren't used here at that time.

Thanks to Brian, you won't need those measurements, but maybe someone else will.

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Brian,Brian wrote:New seal will be on its way to you on Monday Henk, along with some other bits for Dies.

Today I received your parcel. On behalf of Dies, thank you.

Thanks for the oil seal. I removed the old one. I have to make some tools to fit the new one in.

I'm waiting for some other parts. In the mean time I'm cleaning things up an give it a new paint on some spots.

You should see the paint now.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

Sorry for hijacking your thread henk, but I have a question that has to do with lining up the pump, I have the other kind of drive coupling on my pump, the simms one with a rubber star inside and since I exchanged pumps this one seems to "wobble" a little bit, why is it doing that? I also had the pump bracket loose and cleaned it off since everything around it was dirty as ****... Any suggestions?

Essex Lily - Super Major -62 (No. 1618924)

Mr Fordson - Super Dexta -64(dad's)

"Si is est non infractus , effrego is quod animadverto si vos can redintegro is!"

<Ut simplex, validus quod constanter ut ferrum talea campester = Super Major>

Mr Fordson - Super Dexta -64(dad's)

"Si is est non infractus , effrego is quod animadverto si vos can redintegro is!"

<Ut simplex, validus quod constanter ut ferrum talea campester = Super Major>

-

Tjibbe

- Not Quite Blue Yet

- Posts: 31

- Joined: Sun Apr 04, 2010 9:00 pm

- Location: Pretoria in South Africa

Speedy sleeve device

Sounds like a very useful method to prevent seal wear.

I have never seen this, how does it look; how do you fit it on a shaft ?

Tjibbe

I have never seen this, how does it look; how do you fit it on a shaft ?

Tjibbe

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Foxen,

I had the pump and bracket of and was also wondering how to get it back in line.

Put the bracket on and made it hand tight. Than mounted the pump and hand tight it to. Than press the pump forward and feel if it flat to the other coupling and take a look at the coupling to se if the outside of the coupling is even all around. Than thigh up the bracket and then the pump. It's feel and look. You can't measure it. It worked fine with me.

I wanted to use the soft coupling cross but the sales man told me I had to buy a complete coupling, so I used the old pertinax cross.

I had the pump and bracket of and was also wondering how to get it back in line.

Put the bracket on and made it hand tight. Than mounted the pump and hand tight it to. Than press the pump forward and feel if it flat to the other coupling and take a look at the coupling to se if the outside of the coupling is even all around. Than thigh up the bracket and then the pump. It's feel and look. You can't measure it. It worked fine with me.

I wanted to use the soft coupling cross but the sales man told me I had to buy a complete coupling, so I used the old pertinax cross.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

-

Cornishbloke

- Not Quite Blue Yet

- Posts: 9

- Joined: Sat Oct 03, 2009 4:34 pm

- Location: Dark side of a far county