|

Author

|

Topic: Major brakes

|

Kiwi Kev

True Blue Posts: 132

From: Norfolk Island, South Pacific

Registered: Jan 2005

|

posted November 18, 2007 20:52

posted November 18, 2007 20:52

Morning all

How effective should major brakes be???

Should they be able to throw you over the steering wheel if applied hard, merely slow you down, or be able to stop you within a reasonably short distance.

Mine are almost non existant, but have never been that good since I've had her.

Hope someone can help me as to how good they should be.

Thanks

Kiwi KevIP: Logged |

Henk

True Blue Posts: 502

From: Arnemuiden, The Netherlands

Registered: Nov 2004

|

posted November 18, 2007 21:50

posted November 18, 2007 21:50

Good evening Kiwi Kev,On this side of the globe were thinking of going to bed. If you are talking about a New or Power Major, I know that the brakes can bloc the wheels if there working well.

I think it's time to open de the brake drums and check your brake shoes and drums. If the shoes are not worn until the nail, they can be flattened with a file. But be careful. It could be asbestos. If there worn out you have to buy new ones.

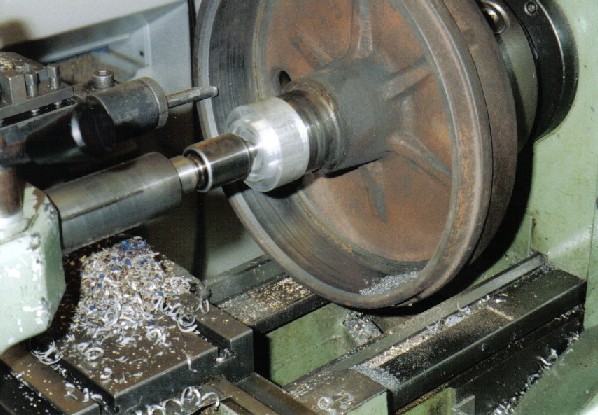

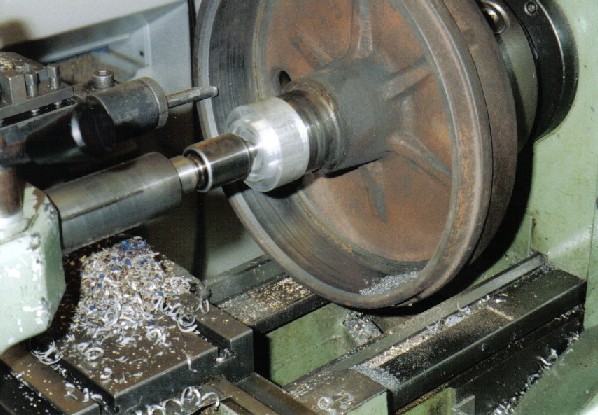

I myself machined the drums.

When reassembled you have to adjust the brakes.  Regards Henk IP: Logged |

tmac

True Blue Posts: 465

From: USA Washington state

Registered: Jul 2002

|

posted November 20, 2007 02:58

posted November 20, 2007 02:58

Henk

Looks like a real nice gap bed lathe  ) That yours? What make is it? It almost looks like a Haligenstat from Germany. ) That yours? What make is it? It almost looks like a Haligenstat from Germany. If you dont mind a couple of suggestions for turning brake drums discs, and flywheels with a clutch face on them, in a standard industrial lathe as opposed to a brake drum lathe. Flywheels with the clutch face and brake drums and discs become very hardened on the surface. It is good to have a solid carbide shank cutting tool and use an indexable TPG 322 1/8R for the finish and a TNG 322 1/16 R for the roughing of the drums. Keep the tail stock center as close to the work as possible on the lathe you are using. Wrap the drum or Flywheels with rubber hold down strips as used on truck covers as tight as you can put the ends together. This will prevent cutter chatter and part squeal. A screen door spring can also be used for a wrap instead. Lead shot in a small bag placed resting on the cutting tool shank will reduce cutter chatter. If you find that either drums or flywheels have deep hard spots that dont cut, if you dont have grinding attachments you can normalize the metal by burning them in a wood fire then slow cooling covered in deep ash. I have done many of these in a lathe and have run into almost every problem that could ever be. Then if all else cutting tools, fails just hunt up a grinder attachment, but be warned grinding is so sloooow ;(( No more than a .0020 inch cut per pass and that is heavy. (I dont do metrics well either) Hope this helps anyone turning these items, as these items can be a real pain  ( I may also add that 2 of the same kind may not cut alike either. ( I may also add that 2 of the same kind may not cut alike either.

quote:

Originally posted by Henk:

Good evening Kiwi Kev,On this side of the globe were thinking of going to bed. If you are talking about a New or Power Major, I know that the brakes can bloc the wheels if there working well.

I think it's time to open de the brake drums and check your brake shoes and drums. If the shoes are not worn until the nail, they can be flattened with a file. But be careful. It could be asbestos. If there worn out you have to buy new ones.

I myself machined the drums.

When reassembled you have to adjust the brakes. Regards Henk

[This message has been edited by tmac (edited November 20, 2007).] IP: Logged |

Henk

True Blue Posts: 502

From: Arnemuiden, The Netherlands

Registered: Nov 2004

|

posted November 20, 2007 19:03

posted November 20, 2007 19:03

I can read you have a lot of experience on the turning machine. The machine is a EMCO Maximat. There small but easy to work on machines. We have two of them. I mean my boss. If I need something quickly to be done, I will take the Emco. We also have two Spanish brands. They work best for turning threats, but vibrate faster as the Emco. The tips and tops you told are very useful. It cost me a lot of efforts to write some the things like that because of my small knowledge of technical English. Most of the times I change the rpm or feed to provide chatter. The rubber strips are third option for me if the peace of lead is not working. Never done a flywheel..By the way, what is a lathe? Regards Henk IP: Logged |

tmac

True Blue Posts: 465

From: USA Washington state

Registered: Jul 2002

|

posted November 20, 2007 19:45

posted November 20, 2007 19:45

Henk

Lathe is a Turning machine, like the Emco you used.NOTE: SEE ARTICLE ON LATHES HERE: http://www.fordsontractorpages.nl/ubb/Forum1/HTML/000068.html Your MaxiMat is a very good Austrian made machine made by Emco Mair. They come in models of V-10, V-11 and I think a V-13. In the USA here we never see much of them in the V-13 model. These are a very expensive machine here. But are more of a tool room precision machine. Nice machines though. Iam surprised that they are now big enough to take a Major drum!  ) Without the gap block removed. Your Spanish machines are not made by Zubel are they? ) Without the gap block removed. Your Spanish machines are not made by Zubel are they? There are many kinds of "lathes" "Turning machines" that are found in machine shops but the 2 most common manual not CNC are: 1. Is the Engine QC quick change Lathe, this has the Norton quick change gear box for cutting threads or the standard old Engine Lathe that has take off change gears to change the Threads feeds. These lathes can be of any size floor standing or bench mounted. 2. The centers Lathe or Turning Lathe, this lathe has no provisions for Threading at all. There are an endless variety of both of these types in use. This Link will show pictures of almost every Lathe and machine that would be suitable to the home shop some pretty big too

http://www.lathes.co.uk/ The term "Engine Lathe" Includes any Lathe that has the ability to cut treads by the use of a differential gearing system, of either the Floor standing or a bench mounted models. My all time favorite was a "DSG" Dean Smith & Grace made in England. It was a 15/19 natural gap bed (no gap block) machine that could take a 1/2 inch cut in a piece of 4140 every pass. This Lathe had 12 hp English rating 15 hp USA rating to the spindle. Now thats a lathe!!

Did have to get used to the right handed carriage wheel though.

[QUOTE]Originally posted by Henk:

[b]

I can read you have a lot of experience on the turning machine. The machine is a EMCO Maximat. There small but easy to work on machines. We have two of them. I mean my boss. If I need something quickly to be done, I will take the Emco. We also have two Spanish brands. They work best for turning threats, but vibrate faster as the Emco. The tips and tops you told are very useful. It cost me a lot of efforts to write some the things like that because of my small knowledge of technical English. Most of the times I change the rpm or feed to provide chatter. The rubber strips are third option for me if the peace of lead is not working. Never done a flywheel..

By the way, what is a lathe?

[This message has been edited by tmac (edited November 23, 2007).] IP: Logged |

Henk

True Blue Posts: 502

From: Arnemuiden, The Netherlands

Registered: Nov 2004

|

posted November 20, 2007 21:07

posted November 20, 2007 21:07

Tmac,We use EMCO Maximat V10. You have to change wheels for threads. The Spanish brand is Pinocho. You can make every thread on these without changing the gear wheels. They have a break pedal over the length of the machine and strong breaks. But you can’t use the starting lever sliding. They feel a bit cheap, and I prefer the left handed Z axle like on the Emco.

I use to work on a shipyard with machine shop. There we made big Sulzer ship engines with piston diameter from 900 or 1000 mm. (40 inches) Real beast. Just type Sulzer on Google and look at the pictures to get an idea. To machine the parts for it, there were turning machines with a diameter up till 3000 mm. This one was used for gearwheels and was made in the year 1919. Others had a length of 10 meters. We used manual as CNC machines. Regards Henk [This message has been edited by Henk (edited November 20, 2007).] IP: Logged |

tmac

True Blue Posts: 465

From: USA Washington state

Registered: Jul 2002

|

posted November 20, 2007 21:32

posted November 20, 2007 21:32

HenkI know what The Spanish brand Pinocho is. And yes it is a dirt cheap machine. Even the schools that bought them here in the USA got rid of them. They are kinda of what we here in the US what we call a cement mixer. ;(( Now a Zubal is a whole different story as it has NO flat ways and has the wider stance of the premium machines. It preforms as good as in light weight machines and has the build of a heavy machine.

I also had great French made machine called a Gallic. It seems though in the European heavy machines that the Germans got the best. But over here USA they just cost to much to buy. Another great medium weight machine that was priced right was the Italian made Grazziano, Sag series, which had strange arrangement of stepped ways. But they were made like a Ferrari Car, each bolt and taper locking pin had a P/N to be fitted in only that single spot.  ) )

quote:

Originally posted by Henk:

Tmac,We use EMCO Maximat V10. You have to change wheels for threads. The Spanish brand is Pinocho. You can make every thread on these without changing the gear wheels. They have a break pedal over the length of the machine and strong breaks. But you can’t use the starting lever sliding. They feel a bit cheap, and I prefer the left handed Z axle like on the Emco.

I use to work on a shipyard with machine shop. There we made big Sulzer ship engines with piston diameter from 900 or 1000 mm. (40 inches) Real beast. Just type Sulzer on Google and look at the pictures to get an idea. To machine the parts for it, there were turning machines with a diameter up till 3000 mm. This one was used for gearwheels and was made in the year 1919. Others had a length of 10 meters. We used manual as CNC machines. Regards Henk [This message has been edited by Henk (edited November 20, 2007).]

IP: Logged |

Henk

True Blue Posts: 502

From: Arnemuiden, The Netherlands

Registered: Nov 2004

|

posted November 21, 2007 22:04

posted November 21, 2007 22:04

Hello TMac,What is or was your occupation? Seems you know a lot about it. Regards Henk

IP: Logged |

tmac

True Blue Posts: 465

From: USA Washington state

Registered: Jul 2002

|

posted November 22, 2007 02:43

posted November 22, 2007 02:43

Hi Henk

I owned and run a machine shop/contract manufacturing operation for the best part of 20 years. I preferred to working in the shop and hired a stuffed shirt and tie guy, manager to run the front office. But started with one 12" lathe (turning machine) Taiwan Made about the same size as your V-10 but with QC Norton box. But by the time I retired/quit I had 17 lathes up and running and 4 milling machines. With a couple of surface grinders and other kinds of machines. I still have a couple of 10x24 inch and a 12x36. The 10 inch Logan flat belt drive bench model with take off change gear, it was purchased new by my Dad, the same year I was born. And still has no more than .0005 in, ball bearing spindle, run out, cant say same for the old 3 Jaw chuck, but that is why I bought a new Buck 6 jaw. Set right. quote:

Originally posted by Henk:

Hello TMac,What is or was your occupation? Seems you know a lot about it. Regards Henk

IP: Logged |

Henk

True Blue Posts: 502

From: Arnemuiden, The Netherlands

Registered: Nov 2004

|

posted November 22, 2007 19:02

posted November 22, 2007 19:02

Hello Tmac,Didn’t know we were colleges.

Mostly I worked on milling machine and for more than 25 years on a Cincinnati Milacro. We had about ten of them trough the whole company. We also used a milling machine named “War Time”. It was used in the production of weapons during WW 2

I also use to work on vertical key machine named “BUTLER”. It was also belt driven and was build between 1920 and 1940. We were not able to find out what year. It was a heavy machine and it was hard labor to make a key or a spline in a hole. Today I worked on the Emco for a V drive belt disc to drive a turning machine for wood. I notice I have been wrong about the type. It's an Emco Maximat V13. Don't know the brands your writing about, but I would keep that Logan in good shape. Funny how you start with brakes and end up talking about shop machine. Regards Henk [This message has been edited by Henk (edited November 22, 2007).] IP: Logged | |

Fordson Bulletin Board

Fordson Bulletin Board

Fordson Major

Fordson Major

Major brakes

Major brakes

) That yours? What make is it? It almost looks like a Haligenstat from Germany.

) That yours? What make is it? It almost looks like a Haligenstat from Germany. ( I may also add that 2 of the same kind may not cut alike either.

( I may also add that 2 of the same kind may not cut alike either.