I was thinking that some people might be interested in how the pump inner parts fit together.

So ill take some pictures during the proces of stripping rebuilding and callibrating.

The callibratong part is going to be done in a creative way youll see it when i get there

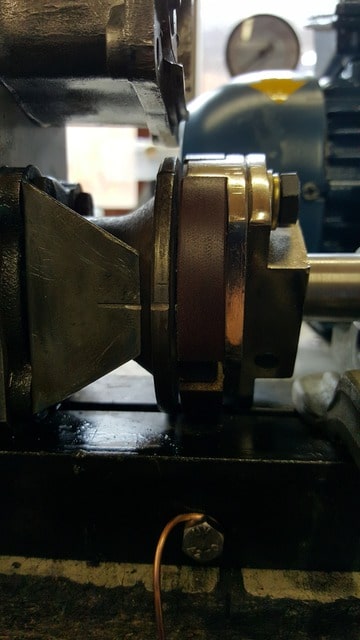

First picture of the completely stript pump.

And a few pictures of damage created by fitting wrong bearings and penetration of water.

The wrong bearings where to wide but they tryed to fit them anyway so they broke of a piece of the bearing lid.

Then they fitted it with a spacer so the cam was not in the center of the plungers.

That created a rotating force on de cam rollers so the pump housing got worn out and the cam rollers where able to rotate.

And then there is the damage from water creating pitting in the camshaft.

In other words this pump is beyond repair.

But today i got me another pump. The guy i bought this pump from had it laying around for 20 years.

In this pump the pumping elements are probably rusted but the ones in my old pump are in reasenble condition.

When i get to stripping the other pump and putting together the best parts of both pumps ill be placing new pics of the work in progress.

Hopfully ending up with a callibrated working pump.

The donor pump:

Dont laugh over my spelling never been typing in other language but dutch