Crank Pulley nut

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Crank Pulley nut

Hi Chaps, I have decided to investigate my knocking noise and poor starting alittle further. So far i have taken the head off and pulled the injectors out. My question is, is there a trick to getting the big nut off the crank pulley??

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Large adjustable and a sharp blow with a hammer.

-

thestig246

- True Blue

- Posts: 105

- Joined: Sun Oct 07, 2012 5:38 pm

Re: Crank Pulley nut

a good hit with a hammer should do it  mine came of quite easyly

mine came of quite easyly

"oNe LiFe LiVe It"!!!

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Thanks guys, will give it ago after work.

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

And his name was BINGO! Gave it a clout with a hammer and its undone!, My next question is I have got all the timing marks lined up on the timing gears, and looking through the fly wheel hole i can see the TDC timing mark. which timing mark on the fuel pump should I be using as there seems to be several lines???

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Minimec pump: 21 degrees BTDC.

Best

Adrian

Best

Adrian

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Thanks Adrian! Everything is looking good with the engine, Bores are nice and smooth and pistons look like a good fit. going to regrind the valve seats this afternoon.

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Either i am being really thick or something isnt right. I have taken acouple pictures of what i think are the timing marks on the pump both are with 21 degrees BTDC showing on the fly wheel. which are the right ones?? (ignore the white tip ex)

these:

Untitled by fixersteve, on Flickr

or this one??

Untitled by fixersteve, on Flickr

with this one lined up its showing 3 degees BTDC on the flywheel??

these:

Untitled by fixersteve, on Flickr

or this one??

Untitled by fixersteve, on Flickr

with this one lined up its showing 3 degees BTDC on the flywheel??

Re: Crank Pulley nut

A bit more info. Steve.

You've said that the marks in both pics line up with the flywheel 21 BTDC. For the bottom pic you also said it lines up with 3 BTDC. I would assume that the latter was with only one complete turn of the flywheel which would indicate that the first pic alignment would be the correct one -- unless you have previously un-coupled the injector pump and are now re-timing it.

Pavel

You've said that the marks in both pics line up with the flywheel 21 BTDC. For the bottom pic you also said it lines up with 3 BTDC. I would assume that the latter was with only one complete turn of the flywheel which would indicate that the first pic alignment would be the correct one -- unless you have previously un-coupled the injector pump and are now re-timing it.

Pavel

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Hi Pavel, Yes you are correct the first picture shows the pump position at 21 BTDC Cyl 1. Which line is the timing line?? There are 9 or so lines there??? I havent had the pump off

Thanks

Steve

Thanks

Steve

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Hi Steve

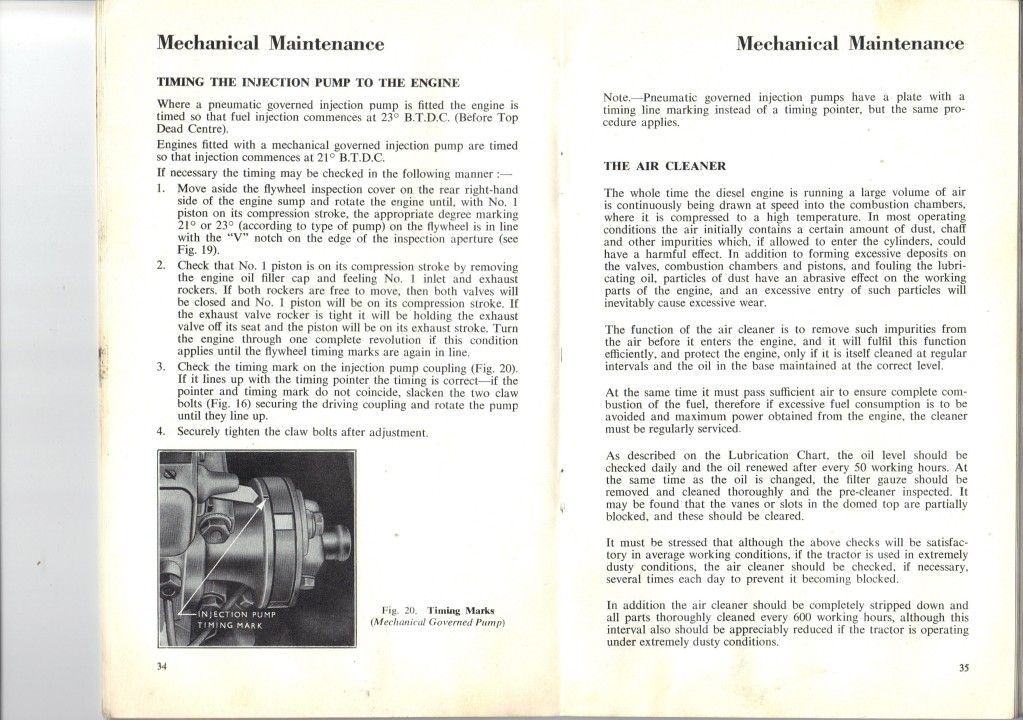

There should be a single mark on the pump coupling (ie not the drive coupling that it mates with). With the flywheel lined up with the notch in the aperture at 21 degrees BTDC, the pump pointer should line up with the drive coupling mark (no 1 cylinder will be on compression stroke).

In your photos I cannot see a mark on the drive coupling. Could you take some more photos? I'll try to upload an image from the NP Super operator's manual that shows all.

Could you take some more photos? I'll try to upload an image from the NP Super operator's manual that shows all.

Best

Adrian

There should be a single mark on the pump coupling (ie not the drive coupling that it mates with). With the flywheel lined up with the notch in the aperture at 21 degrees BTDC, the pump pointer should line up with the drive coupling mark (no 1 cylinder will be on compression stroke).

In your photos I cannot see a mark on the drive coupling.

Best

Adrian

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Thanks adrian, I will take some more pictures tomorrow when im at work. I think there is another mark after the series of lines on the pump side of the coupling. should the marker on the pump be on the side or on top??

Cheers

Steve

Cheers

Steve

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

I Have taken some more pictures this morning,

Showing flywheel at 21 BTDC Compression Cyl 1

Untitled by fixersteve, on Flickr

Timing gear marks

Untitled by fixersteve, on Flickr

Piston Position

Untitled by fixersteve, on Flickr

Pump drive position

Untitled by fixersteve, on Flickr

Untitled by fixersteve, on Flickr

Showing flywheel at 21 BTDC Compression Cyl 1

Untitled by fixersteve, on Flickr

Timing gear marks

Untitled by fixersteve, on Flickr

Piston Position

Untitled by fixersteve, on Flickr

Pump drive position

Untitled by fixersteve, on Flickr

Untitled by fixersteve, on Flickr

Re: Crank Pulley nut

If you have not uncoupled the inj. pump, I would be inclined to leave it timed as is. Your timing position appears, as near as damn it, to be the same as mine.

I've always wondered why the timing plate [?] attached to top of the pump bears no relationship to mark on the drive shaft.

Pavel

I've always wondered why the timing plate [?] attached to top of the pump bears no relationship to mark on the drive shaft.

Pavel

Re: Crank Pulley nut

PS -I meant the side mark -- which is the only one on mine.

Pavel

Pavel

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Thanks Pavel, The only reason i was questioning the pump timing was the fact that she wont start without a sniff of ether..... Ive reground all the valves and checked the bores for pitting, they are beautifully clean and smooth. Also i have stripped and cleaned all the injectors. Any other ideas as to what would cause her to be bad at starting would be greatfully recived.

Steve

Steve

-

origin

- Not Quite Blue Yet

- Posts: 47

- Joined: Fri May 11, 2012 1:49 am

- Location: Lloydminster, SK, Canada

Re: Crank Pulley nut

I'm keeping an eye on this thread, because this is exactly the same issue that I'm having with my Minimec...

1962 Fordson Super Major w/ Robin FEL (6' rough cut mower)

1978 Ford LGT 165 (w/ 42" Mower, 36" Tiller, and 48" Plow)

1976 Ford LGT 165 (Parts Tractor)

1974 Ford LGT 145 (50" Mower, 42" 2 stage Blower, Sleeve Hitch, Cultivator)

1978 Ford LGT 165 (w/ 42" Mower, 36" Tiller, and 48" Plow)

1976 Ford LGT 165 (Parts Tractor)

1974 Ford LGT 145 (50" Mower, 42" 2 stage Blower, Sleeve Hitch, Cultivator)

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Steve and guys

Please find below a photo of the New Performance Super Major operator's manual.

It appears from your photos that the coupling has been changed to accommodate a quiet running pump drive spacer. This may well be causing the problem. If you are sure that the bores are not worn and that the valves are seating correctly ie you have good compression, there would be no need for ether to get her going.

I have no experience of this coupling. Does the pump side of the coupling have a mark as shown in the photo?

Best

Adrian

Please find below a photo of the New Performance Super Major operator's manual.

It appears from your photos that the coupling has been changed to accommodate a quiet running pump drive spacer. This may well be causing the problem. If you are sure that the bores are not worn and that the valves are seating correctly ie you have good compression, there would be no need for ether to get her going.

I have no experience of this coupling. Does the pump side of the coupling have a mark as shown in the photo?

Best

Adrian

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Thanks Adrian, There is a mark on the pump coupling but its at 9 oclock to where the timing mark on the pump is when im at 21 BTDC Compression

Have got the new cylinder head gasket, just waiting for the block to head seal to come and then i can put her back together to see if regrinding the valves and cleaning the injectors has made any difference.

I have got a compasite head gasket, do i need to put any sealer on it???

Cheers

Steve

Have got the new cylinder head gasket, just waiting for the block to head seal to come and then i can put her back together to see if regrinding the valves and cleaning the injectors has made any difference.

I have got a compasite head gasket, do i need to put any sealer on it???

Cheers

Steve

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Steve

I would have thought that that the quiet running coupling would have a mark positioned to allow for the different configuration. I don't think you'll get enough adjustment on the claw bolts to bring it back to 12 o'clock. Sorry, this needs another, wiser head than mine!

Re gasket, thin film of blue Hylomar on the top of the block and on the top surface of the gasket.

Best

Adrian

I would have thought that that the quiet running coupling would have a mark positioned to allow for the different configuration. I don't think you'll get enough adjustment on the claw bolts to bring it back to 12 o'clock. Sorry, this needs another, wiser head than mine!

Re gasket, thin film of blue Hylomar on the top of the block and on the top surface of the gasket.

Best

Adrian

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Thanks Adrian, I will see what she starts like once i have got the head back on. If i still have a problem i will look at the timing in more detail.

All the Best

Steve

All the Best

Steve

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Resist the temptation to reach for the Easy-Start!

That coupling is throwing things out - that's my best guess. Have you considered getting it changed to the good old clattering one that most of us have?!

Best

Adrian

That coupling is throwing things out - that's my best guess. Have you considered getting it changed to the good old clattering one that most of us have?!

Best

Adrian

-

Fixersteve

- True Blue

- Posts: 212

- Joined: Wed Nov 21, 2012 12:34 am

- Location: West Cornwall, UK

Re: Crank Pulley nut

Until you said just now about it being a modified coupling i had no idea. I will see what she starts like when i put the head back on.

-

AdrianNPMajor

- True Blue

- Posts: 1174

- Joined: Sat Aug 13, 2011 6:11 pm

Re: Crank Pulley nut

Steve

If you compare yours with the one in the photo in the operator's manual (see pic above), you'll see the difference. Yours is designed to run more quietly, which is nice, as long as it runs!

Best

Adrian

If you compare yours with the one in the photo in the operator's manual (see pic above), you'll see the difference. Yours is designed to run more quietly, which is nice, as long as it runs!

Best

Adrian

Re: Crank Pulley nut

Steve,

You mention excessive diesel knock. This usually indicates the injection pump timing is too far advanced. Also the exhaust smoke will be blacker than normal at a steady fast idle.

I would be inclined to use the graduations on top to retard the pump by one line as a start.

Pavel

You mention excessive diesel knock. This usually indicates the injection pump timing is too far advanced. Also the exhaust smoke will be blacker than normal at a steady fast idle.

I would be inclined to use the graduations on top to retard the pump by one line as a start.

Pavel