I purchased a second hand 8" PTO wood chipper from a guy in Oregon who apparently never sized his PTO shaft, resulting in binding and a bent Jack Shaft.

Video of bent shaft;

https://www.youtube.com/watch?v=wr6E0YebQSM

After contacting several machine shops, and getting a response from only one of them, I was told I could expect a repair bill of up to $500. Well, I can buy the tools to fix it for less than that.

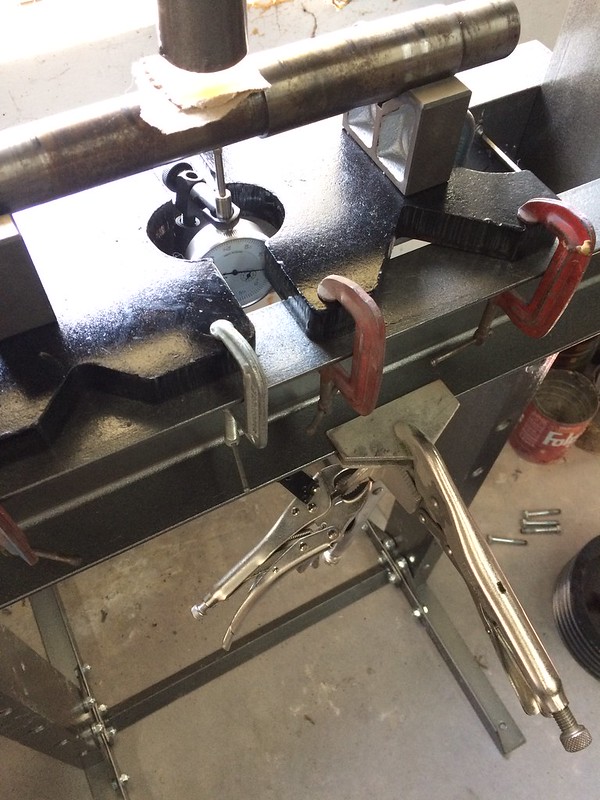

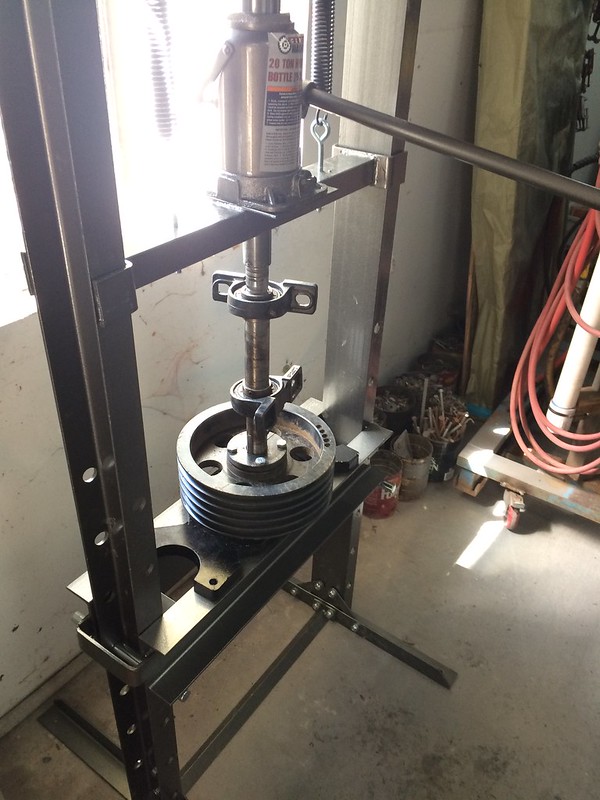

So that's what I did. I took advantage of a Mothers Day sale at Harbor Freight to pick up a 20 ton shop press and a clamp on dial indicator, and sourced a couple of V-Blocks from Amazon.

Also found this as a guide, which I will reference in my repair;

http://www.repairengineering.com/shaft- ... ening.html

So far, I've assembled my shop press, and disassembled the shaft assembly;

Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on Flickr Untitled by CASEY, on Flickr

Untitled by CASEY, on FlickrI expect to receive my V-Blocks tomorrow, which should allow me to proceed with the appropriate repair procedures.

If anyone has any advice, I'm open ears, this will be my first attempt at a shaft straightening. I know quite a bit about working with sheet metal, as I am a professional auto body man, and painter, but this is a bit outside of my experience zone, so I'm just seeking out anecdotes from those who've been there and done that.