Brakes

Brakes

My next project on our old power major is the brakes. They have seized on the on position and have been like that for, 20 years or so. How come the brakes are on like a separate shaft to the wheels ? What is the reason for this ? Is it possible to do the brakes without taking the back wheels of?

And lastly and most importantly, I know on some of these old vehicles the drum brakes have asbestos in them. Is this the case with the power major brakes ? If they do have asbestos in them, how can I safely work on them ?

And lastly and most importantly, I know on some of these old vehicles the drum brakes have asbestos in them. Is this the case with the power major brakes ? If they do have asbestos in them, how can I safely work on them ?

Hello Ivin,

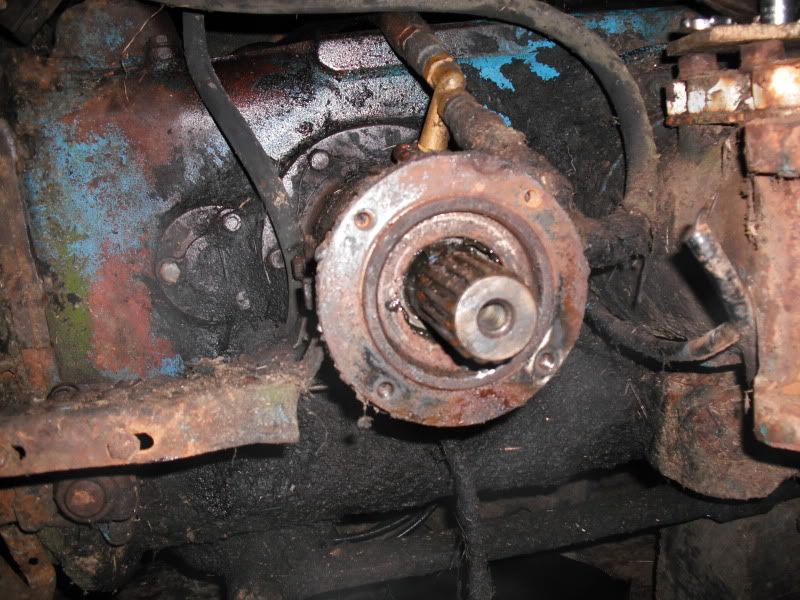

The brakes are on the bull pinion shafst, which are connected to the differential, which lies in the same axis as the brake shafts.

The rear weal half shafts are driven through big gears from these bull pinion shafts.

The bull shaft rotates far faster then the rear wheel shaft, thus having a lower torque and higher speed, which makes smaller brakes as effective as big brakes in the rear axle shaft.

Usually these brakes are with asbestos, which makes it very difficult to work safely. Wearing protective masks and not using an air gun are the easiest tips I have for you. Flush out the dust instead of blowing it away.

Best regards

Emiel

The brakes are on the bull pinion shafst, which are connected to the differential, which lies in the same axis as the brake shafts.

The rear weal half shafts are driven through big gears from these bull pinion shafts.

The bull shaft rotates far faster then the rear wheel shaft, thus having a lower torque and higher speed, which makes smaller brakes as effective as big brakes in the rear axle shaft.

Usually these brakes are with asbestos, which makes it very difficult to work safely. Wearing protective masks and not using an air gun are the easiest tips I have for you. Flush out the dust instead of blowing it away.

Best regards

Emiel

Best regards

Emiel

N 1937, E27N 1948, 8N 1949, E27N 1950, E1A Diesel 1953, E1ADKN PP 1956, Dexta 1959, NH Clayson M103 1964

Emiel

N 1937, E27N 1948, 8N 1949, E27N 1950, E1A Diesel 1953, E1ADKN PP 1956, Dexta 1959, NH Clayson M103 1964

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Best to wash the dust away. I did the brakes on my Power Major a few years ago. I found that the cheepest way was to have my old shoes relined. Besure that the brake cables are free and working smoothly. I had to remove the rear wheels to do the brake job. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

-

henk

- Site Governance Team & Expert Team

- Posts: 2099

- Joined: Wed Apr 16, 2008 8:56 pm

- Location: Arnemuiden, The Netherlands

- Contact:

Ian,

I would suggest to close the drum brake and clean up all from the rear axle to the brake pedals.

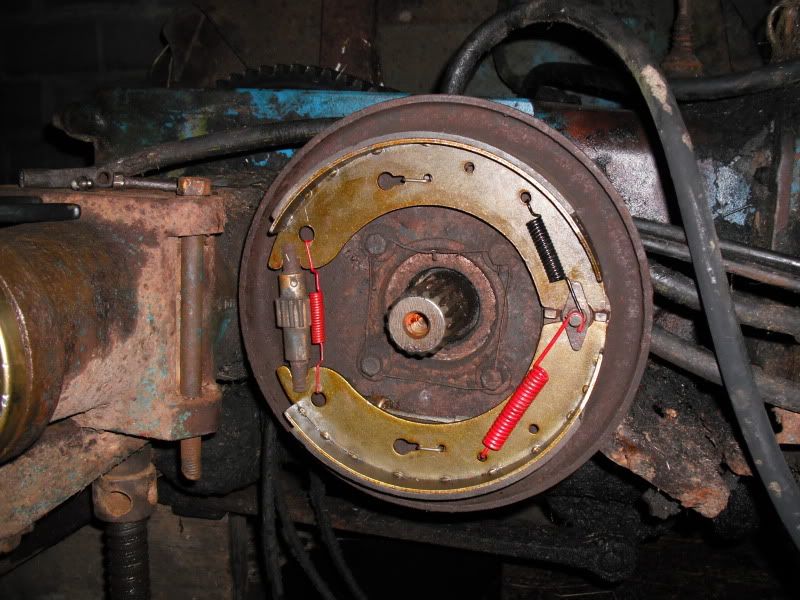

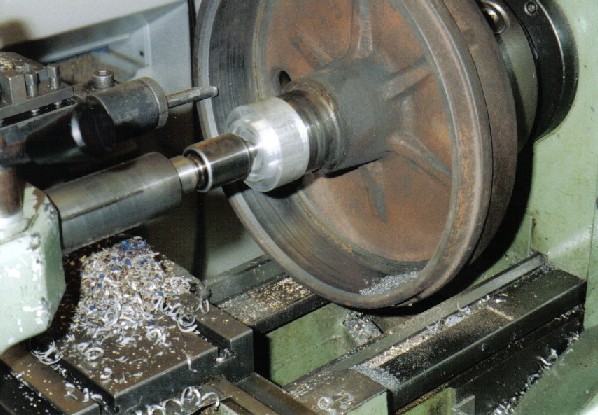

The drum brake is complete, but the shoe is worn to much. The drum could me worn so you have to machine it, like on the picture. I think your cable will be worn also to much and the bushes on the brake pedals could also be worn. So you have to check the whole line and clean it and undo it from the rust.

I would suggest to close the drum brake and clean up all from the rear axle to the brake pedals.

The drum brake is complete, but the shoe is worn to much. The drum could me worn so you have to machine it, like on the picture. I think your cable will be worn also to much and the bushes on the brake pedals could also be worn. So you have to check the whole line and clean it and undo it from the rust.

Kind regards, Henk

Fordson New Major February 1957 Mark I

Fordson New Major February 1957 Mark I

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

Man o man... that is rusty. Henk is right, the shoes are shot and need to be relined as they are down to the rivets. I would also renew the grease seals. Start on one end and free up everything as you go. I wonder if they ever greased the brake cables???Use plenty of never sieze on the adjusters after you get them freed up and working smoothly. I use a pair of visegrip locking pliers to remove brake springs all the time. Dandy Dave!

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

Those are the original brake shoes on the tractor. They had never once been serviced, so they are definitely going to be asbestos. Might be better I think to just buy new shoes rather than try and get them re-lined, or attempt to do it myself. They seem to be about £12 for a shoe. The drum itself looks pretty good inside. The tractor had been sat out in a field for half a century, so everything on it is pretty damn rusted.

-

Dandy Dave

- True Blue

- Posts: 1859

- Joined: Thu Apr 02, 2009 2:49 am

- Location: Copake, NY

When I did the brakes on my Power Major, I inquired at my New Holland dealer about new brake shoes. The quote I was given was like $500 US in parts to do the Brake Job. Just about knocked my socks off... And then I discovered Agriline after I did the brake job. When I took it apart, It was outside, and I high pressure washed everything before I pulled it apart. Dandy Dave!

http://www.agrilineproducts.com/

http://www.agrilineproducts.com/

Have a Fordsonful day Folks!

1960 Fordson Power Major

1960 Fordson Power Major

I don't seem to be having much luck with the brakes at the moment.

The old brake cable snapped when I took it off. The bolt that holds the cable to the brake pedal broke apart when I tried to take that off. The bolt that holds the cable to the brake back plate snapped when I tried to put a new cable on. One of the springs broke when I tried to put new shoes on :O

I've decided to just try and replace everything, however I don't know where I can get a new part circled in the picture. The part that connects the brake cable to do the pedal. The metal there is so rusted I can't get the old end of the cable out. It was so rusted I couldn't even move the nut on it.

-

Jerry Coles

- True Blue

- Posts: 546

- Joined: Thu Apr 17, 2008 9:09 pm

- Location: Camerton, Bath, UK

From what I can see from the photos you only have the axle supported on a jack. PLEASE make sure you have adequate support other than the jack such as axle stands as your efforts in repairing the tractor might cause it to move, slip and bang! you are injured.

Theres a lot of metal being supported there and you must make sure it is always safe to work on.

Regards

Jerry

Theres a lot of metal being supported there and you must make sure it is always safe to work on.

Regards

Jerry

Jerry Coles

Camerton, Bath, UK

West Highland White Terriers, Dexta's, E27N's and DUKW's

Camerton, Bath, UK

West Highland White Terriers, Dexta's, E27N's and DUKW's

could someone take a picture of the foot pedal area from the top and underside so I can see what it looks like ?

This area on my tractor is so rusted I'm not really what what it is meant to look like and what is missing. It's so rusted also the left and right foot pedals are also stuck together.

Also are the brake springs different on the live driver power majors, and the normal power majors ?

This area on my tractor is so rusted I'm not really what what it is meant to look like and what is missing. It's so rusted also the left and right foot pedals are also stuck together.

Also are the brake springs different on the live driver power majors, and the normal power majors ?

Hello Ian,

I think that it is the easiest to pull the old one out. Try to screw a screw into the metal housing of the seal and pull the screw.

[img]www.gt-hechttechniek.nl/.../schroef_HOBAU.jpg

[/img]

Installing the new one it tricky, because you can easily damage a seal on the splined shaft.

Best regards

Emiel

I think that it is the easiest to pull the old one out. Try to screw a screw into the metal housing of the seal and pull the screw.

[img]www.gt-hechttechniek.nl/.../schroef_HOBAU.jpg

[/img]

Installing the new one it tricky, because you can easily damage a seal on the splined shaft.

Best regards

Emiel

Best regards

Emiel

N 1937, E27N 1948, 8N 1949, E27N 1950, E1A Diesel 1953, E1ADKN PP 1956, Dexta 1959, NH Clayson M103 1964

Emiel

N 1937, E27N 1948, 8N 1949, E27N 1950, E1A Diesel 1953, E1ADKN PP 1956, Dexta 1959, NH Clayson M103 1964

There are two seals, one at both ends of the shaft. I think it would be better to chance both seals to ensure that oil doesn't find its way into the brakes. I believe that the shaft was designed to be that long just to improve the oil sealing capability.Ian wrote:so I don't need to remove the entire shaft?

I'll attach a couple of pictures from the repair manual. I did the job a little differently than what the manual says, though. I just pulled the trumpet housing (part no 4 in the picture) from around the shaft leaving the shaft and the pinion assembly in place. It worked for me and so far there has been no leaks.

I got them off of ebay for around £50 for both wheels. I was going to get them off of agriline, but I would have had to have hammered off the old asbestos linings, and riveted new ones on. Which I didn't especially want to do. The ones I bought off ebay, the linings were already bonded to the shoes.Tiger wrote:Hi Ian, Where did you get your pads from and how much.

My right brakes working a bit and the left pedal goes to the floor and nothing. So i reckon this job will be on my list soon

Thanks Chris